Rockwell Automation 1503 OEM Starter Frame Components Installation Manual User Manual

Page 40

3-6

Adjustments

1503-IN050E-EN-P – June 2013

To Reduce the Gap Distance

5) Loosen the two screws in the stop bracket and move the stop bracket

up against the interlock lever.

6) With the feeler gauge positioned in the gap, move the interlock lever

and the stop bracket closer to the isolation switch operating lever to

reduce the gap space. Tighten the stop bracket screws.

7) Tighten the nylock nut until it is snug against the contactor operating

lever. Do not overtighten the nylock nut as it will move the interlock

lever and reduce the gap. Proceed to Step 11.

To Increase the Gap Distance

8) Loosen the two screws in the stop bracket and move the stop bracket

away from the interlock lever.

9) Loosen the nylock nut until the gap reaches the desired size.

10) Move the stop bracket until it just touches the interlock lever and

tighten the screws.

11) Apply Loctite 290 (or equivalent adhesive) to the stop bracket screws

and torque the screws to 6 ft.-lb. (8 N•m).

12) Move the isolation switch handle to the ON position.

13) Manually close the contactor by attaching locking pliers to the contac-

tor operating lever and pushing down until the armature plate contacts

the magnetic cores (see Figure 3.7). Verify that the interlock lever

overlaps the isolation switch operating lever by at least 0.125 in. (3 mm)

(see Figure 3.8).

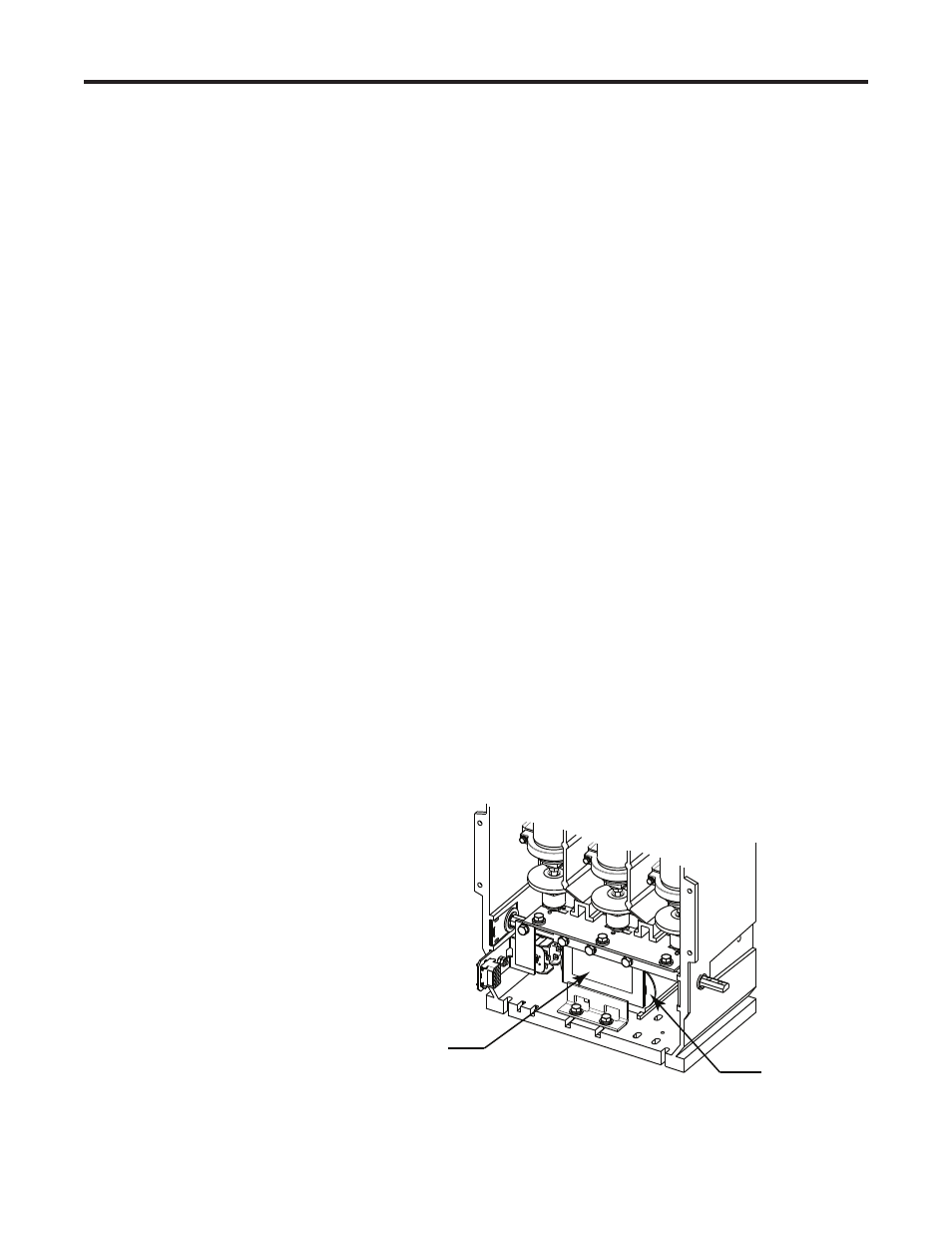

Figure 3.7 – Closing Contactor Manually (Some parts not shown)

Contactor Interlock Rod

Adjustment (cont.)

Magnetic Core

Armature Plate