Power connections – Rockwell Automation MV SMC Flex OEM Components User Manual

Page 27

Power Stack Installation

4-11

1503E-IN001E-EN-P – June 2013

A T T E N T I O N

A T T E N T I O N

To avoid shock hazard, lock out incoming

power to power cables when completing

connections. Failure to do so may result in

severe burns, injury or death.

It is the responsibility of the OEM to ensure that

suitable line and load cables are used to satisfy

the requirements of the equipment and meet

local electrical codes.

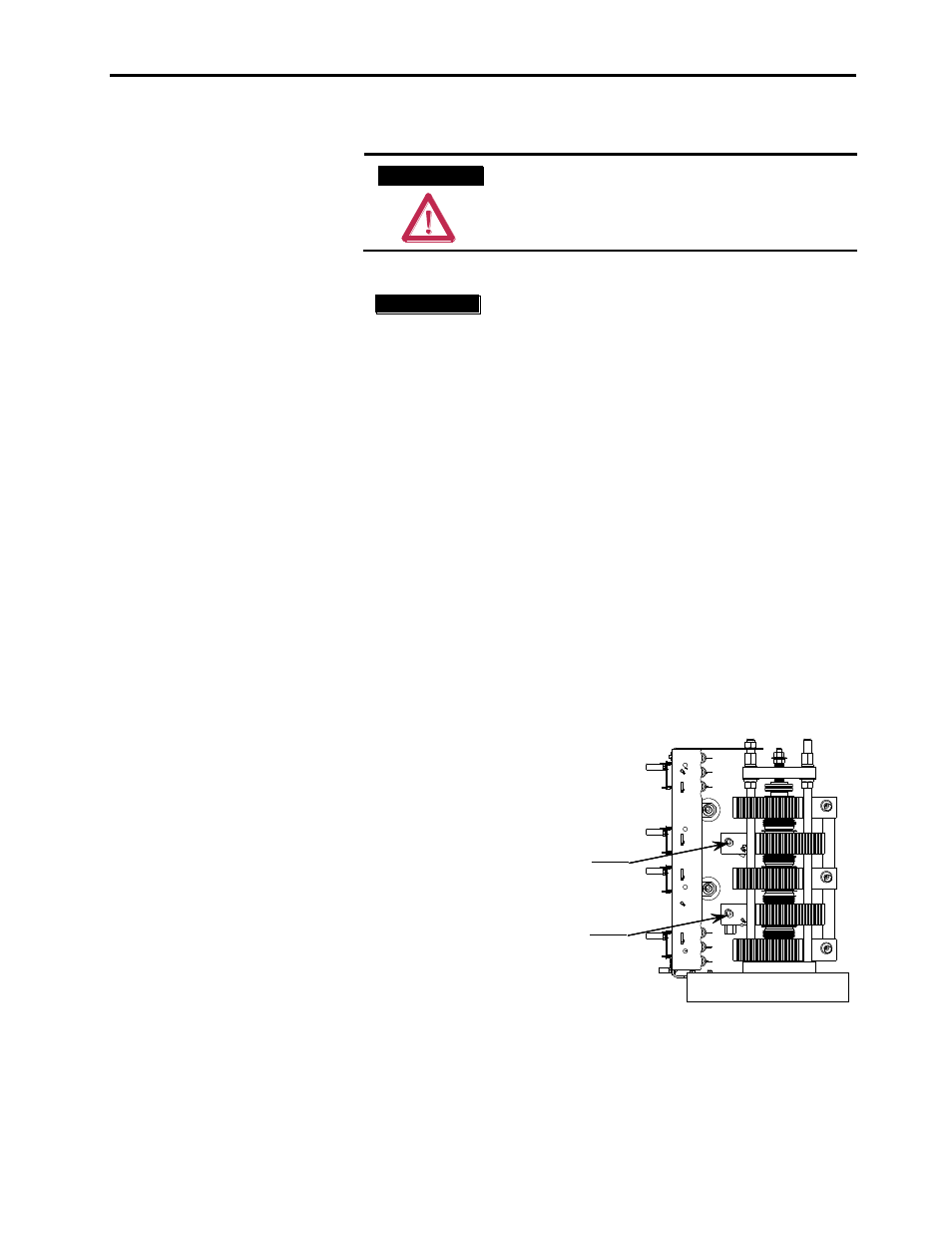

1) Use appropriate cable lugs to attach suitable line cables to the

line cable terminal (upper power terminal) of the heatsink

assembly. The terminal is predrilled with a mounting hole with a

diameter of 10.3 mm (0.406 in.). The holes are suitable for M10

(3/8 in.) hardware. Refer to Figure 4.8 for the terminal location.

Torque the fastening hardware to the specifications shown in

Table 4.D.

2) Use cable lugs to attach suitable load cables to the load cable

terminal (lower power terminal) of the heatsink assembly. Refer

to Figure 4.8 for the terminal location. Torque the fastening

hardware to the specifications shown in Table 4.D.

3) Refer to Chapters 6 and 7 for a typical wiring diagram to

determine the required connections. Appendix B includes a

typical schematic for a complete soft starter unit.

Line Cable Terminal

10.3 mm (0.406 in.) diameter

(All stacks in SMC frame have similar configuration)

Right Side View

Load Cable Terminal

10.3 mm (0.406 in.) diameter

Line Cable Terminal

10.3 mm (0.406 in.) diameter

(All stacks in SMC frame have similar configuration)

Right Side View

Load Cable Terminal

10.3 mm (0.406 in.) diameter

Figure 4.8 - Heatsink Assembly Power Connections

(4160V, 360A heatsink shown)

I M P O R T A N T

I M P O R T A N T

Power Connections