Anchoring, Torque requirements – Rockwell Automation MV SMC Flex OEM Components User Manual

Page 13

Power Stack Frame Installation

3-5

1503E-IN001E-EN-P – June 2013

Anchoring

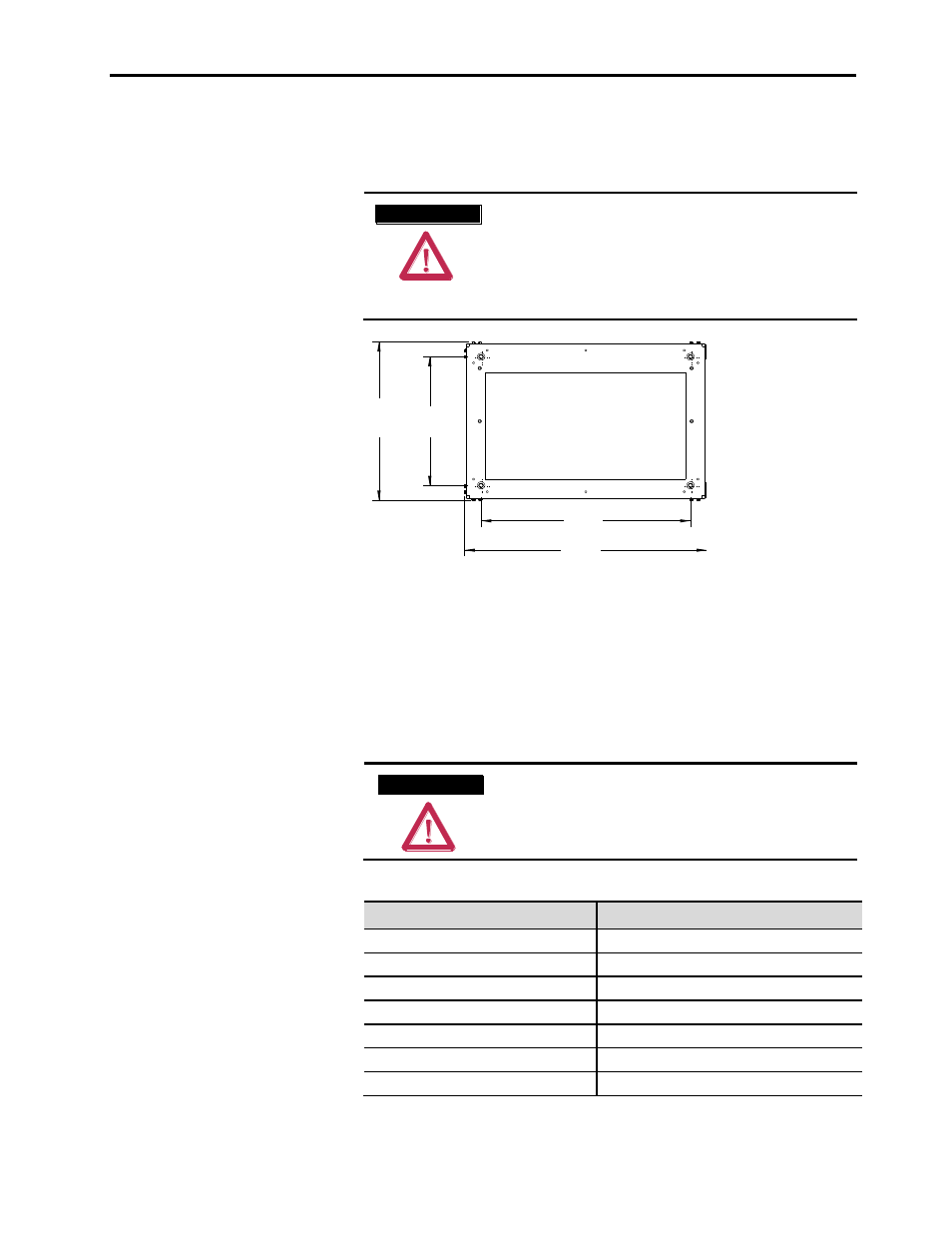

Mounting holes are provided in the frame and are suitable for 0.5 in.

(M12) diameter anchor bolts (refer to Figure 3.5).

A T T E N T I O N

A T T E N T I O N

The frame is designed to be anchored in the

upright position and on a level surface. Do not

attempt to mount the frame upside down or at

any angle that is not level. Improper anchoring

may cause injury to personnel and/or damage to

the equipment.

640

[25.2]

521

[20.5]

778

[30.6]

900

[35.4]

(All dimensions in millimeters [inches])

Front

Figure 3.5 – Frame Mounting Hole Locations (Bottom View)

Torque Requirements

All electrical connections must be torqued to the specifications shown

in Table 3.C.

A T T E N T I O N

A T T E N T I O N

Ensure that all electrical connections are torqued

to the correct specification. Failure to do so may

result in damage to the equipment and/or injury

to personnel.

Table 3.C – Torque Requirements

Hardware

Recommended Torque

1/4 in.

6 ft·lb (8 N·m)

5/16 in.

11 ft·lb (15 N·m)

3/8 in.

20 ft·lb (27 N·m)

1/2 in.

48 ft·lb (65 N·m)

Control Wire Terminals

2.0 – 3.3 in·lb (0.2 – 0.4 N·m)

CLGD Power Assembly Terminals

50 in·lb (5.6 N·m)

SMC Flex Control Module Terminals

5 in·lb (0.6 N·m)