Torque requirements, Power stack mounting – Rockwell Automation MV SMC Flex OEM Components User Manual

Page 20

4-4

Power Stack Installation

1503E-IN001E-EN-P – June 2013

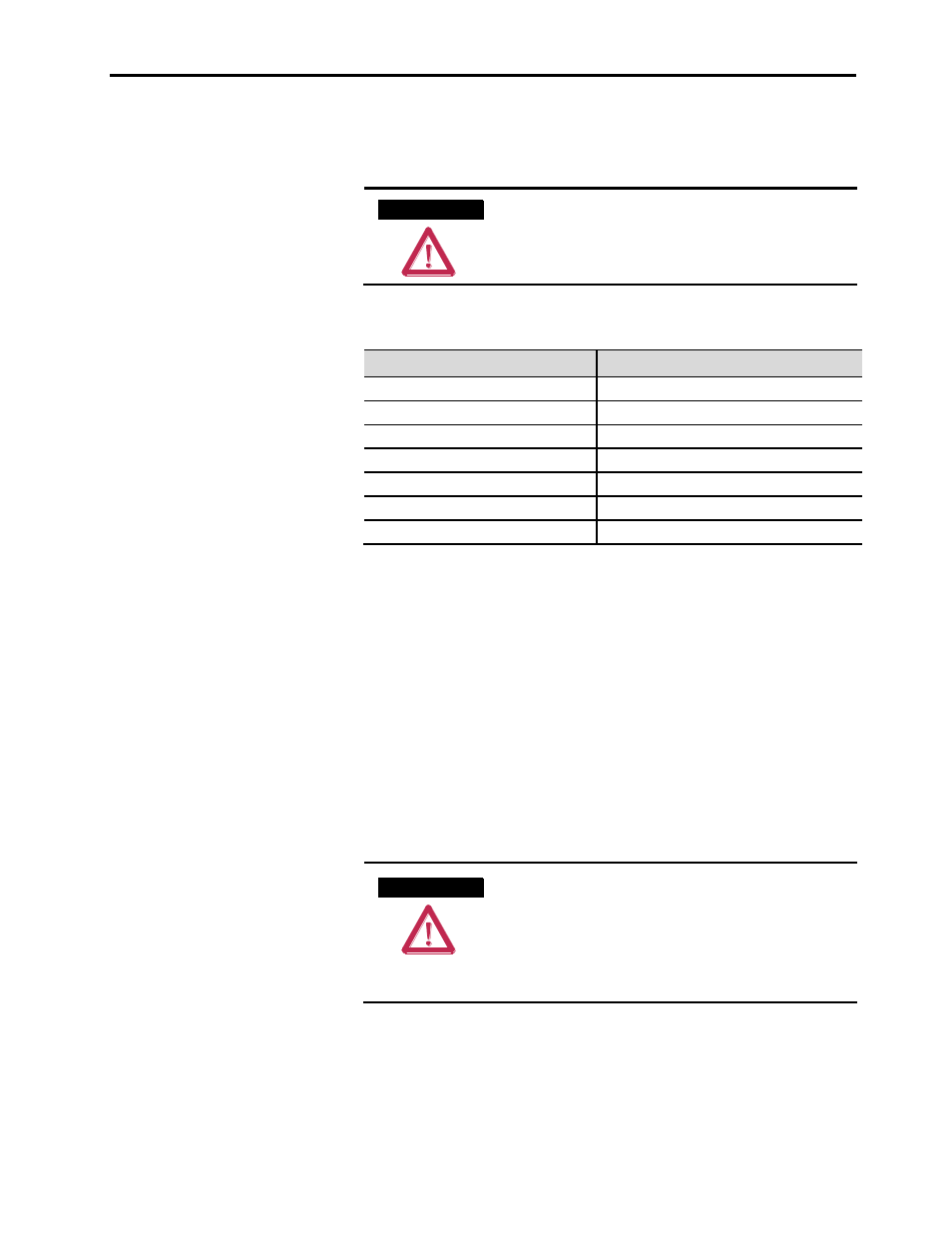

Torque Requirements

All electrical connections must be torqued to the specifications shown

in Table 4.D.

A T T E N T I O N

A T T E N T I O N

Ensure that all electrical connections are torqued

to the correct specification. Failure to do so may

result in damage to the equipment and/or injury

to personnel.

Table 4.D – Torque Requirements

Hardware

Recommended Torque

1/4 in.

6 ft·lb (8 N·m)

5/16 in.

11 ft·lb (15 N·m)

3/8 in.

20 ft·lb (27 N·m)

1/2 in.

48 ft·lb (65 N·m)

Control Wire Terminals

2.0 – 3.3 in·lb (0.2 – 0.4 N·m)

CLGD Power Assembly Terminals

50 in·lb (5.6 N·m)

SMC Flex Control Module Terminals

5 in·lb (0.6 N·m)

Power Stack Mounting

Power stacks are to be mounted in a vertical orientation in order to

provide adequate component cooling. Mount the heatsink in a

suitable location using the mounting holes provided in the assembly.

Use M10 (3/8”) or similar hardware for the mounting hole dimensions

of 10.7 mm x 15.9 mm (0.421in. x 0.625 inches).

Power stacks rated 180/360A, up to 4799V, are provided with

mounting brackets (as shown in Figures 4.2 and 4.4). The mounting

brackets should be affixed to a horizontal surface, and the power stacks

slide into and bolt to the mounting brackets.

A T T E N T I O N

A T T E N T I O N

Maintain sufficient clearance between the power

phases and between phases and grounded

surfaces. Refer to local electrical codes to

determine the required clearance. Failure to do

so may result in injury to personnel or damage to

the equipment.