Original instructions, Applications and application require- ments, Applications – Rockwell Automation 440L GuardShield PAC Type 4 Safety Light Curtain User Manual

Page 9: Application requirements

GuardShield™ PAC Safety Light Curtain Installation Instructions

7

Original instructions

The test input must be configured via a dip-switch located in the

GuardShield PAC transmitter.

Beam Coding

If several safety light curtains are operating in close proximity to

one another, it is possible that the transmitter’s infrared light from

one GuardShield PAC system is “seen” by another GuardShield

PAC system’s receiver. This would cause a “nuisance” stop. To

prevent this optical interference, the GuardShield PAC has the

ability to have the transmitter generate different beam patterns,

which is referred to as “Beam coding.” Selection and activation of

beam coding is accomplished through dip-switch settings in both

the transmitter and receiver.

The following settings are available in the GuardShield PAC safety

light curtain; noncoded and coded.

Applications and Application Require-

ments

Applications

The GuardShield PAC multi-beam safety light curtain may be used

as an opto-electronic fence; detecting the presence of personnel

as they pass through the sensing field or for safeguarding access

to a hazardous area or machine process. Used in combination

with corner mirrors, the GuardShield PAC multi-beam safety light

curtains provide multiple-side access detection.

When using corner mirrors to protect multiple sides of a machine

or work cell, the GuardShield PAC with integrated laser alignment

is the preferred solution. Activation of visible laser light allows

positioning and adjustment of the transmitter, receiver and

corner mirrors.

A typical system configuration for access detection to a hazardous

area or machine process is to have the GuardShield PAC multi-

beam safety light curtain connected to an external module along

with two or four sensors. The external module allows material to

pass through the GuardShield PAC multi-beam’s sensing field

without stopping the machine or equipment as long as the

muting conditions are met. As the material is moving through the

process, the GuardShield PAC multi-beam’s sensing field is

interrupted and the outputs switch to the OFF state. However, if

the muting module sensors are interrupted with the proper

timing, the module disregards the GuardShield PAC multi-beam’s

outputs and remains in the ON condition, allowing the machinery

or equipment to continue operation.

If the muting sensors are not interrupted and maintained in the

required timing and or sequence, the muting module will switch

OFF when the GuardShield PAC multi-beam’s sensing field is

interrupted.

IMPORTANT

Beam coding improves resistance to optical

interference.

Beam coding increases the system’s response

time, which may also increase the required

safety distance. Refer to Safety Distance

calculations on page 9 of this manual.

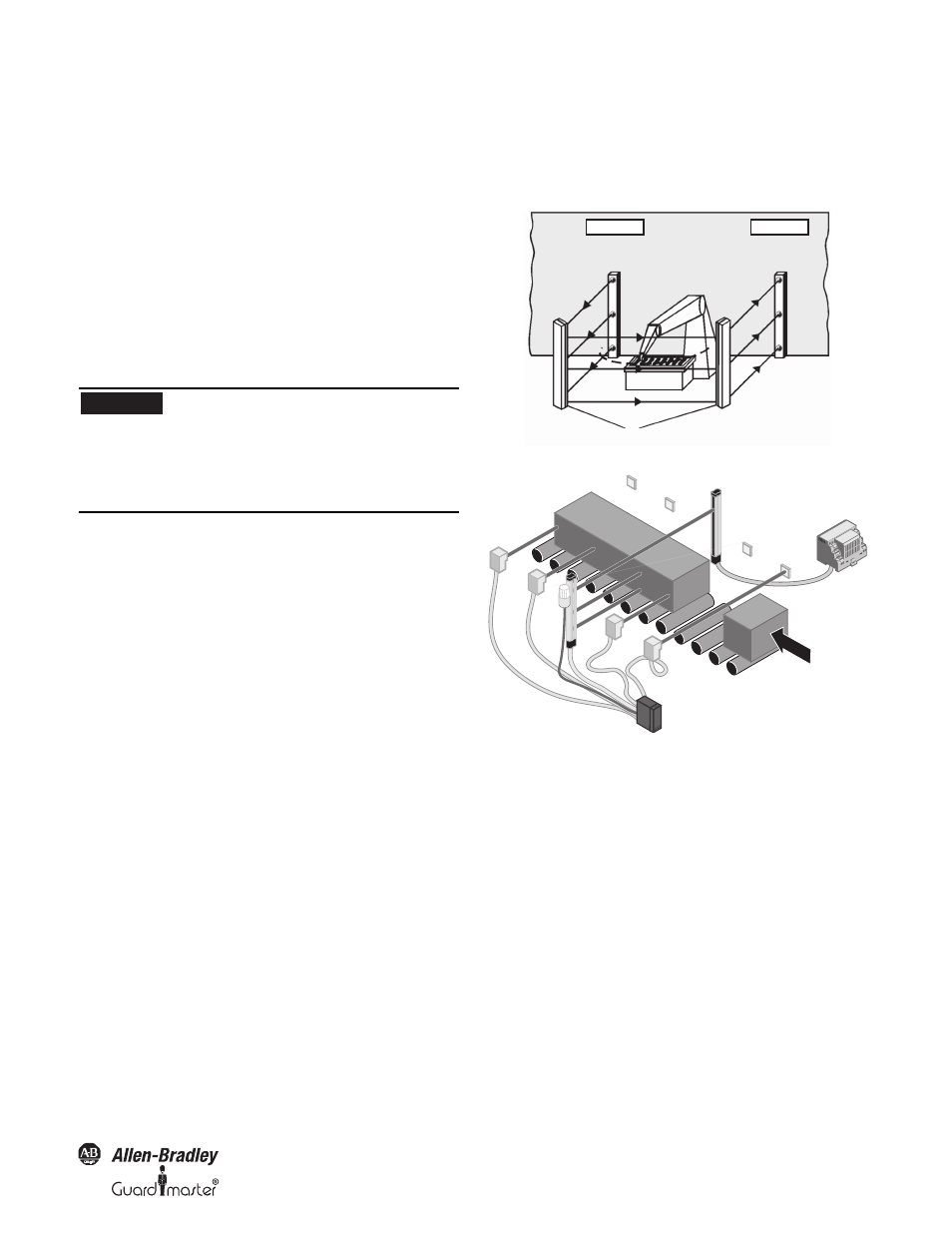

Figure 2 is an example of a GuardShield PAC three-beam safety

light curtain used as an opto-electronic fence with corner mirror

columns.

Figure 3 is an example of a GuardShield PAC three beam with four

retroreflective sensors and an external muting module.

Figure 2: GuardShield PAC three beam with corner mirror columns

Figure 3: GuardShield PAC three beam with muting module

Application Requirements

The protective functions of the PAC can only be used properly

when the following conditions are satisfied:

• The machine or installation must be controlled electrically.

• It must be possible to stop hazardous machine movement.

• The PAC must be installed so that entry into the danger

zone interrupts one or more of the light beams.

The light beam diameter of 23 mm (0.90 in.) must be fully

covered, to assure a change in state of outputs.

Release can only be achieved with the use of a restart switch.

The restart switch must be located such that it cannot be pressed

from inside the danger zone.

The GuardShield PAC should be mounted such that upon

interruption of the light beam, the dangerous location can only

be reached if the dangerous condition of the machine has been

stopped. The requirement for this is that there is a proper safety

GuardShield

GuardShield

PAC

Transmitter

PAC

Receiver

Corner Mirror

Roller Work Path

Power

Supply

Work

Piece

Muting

Module

Work

Piece