Original instructions, The ansi safety distance formula, European safety distance formula – Rockwell Automation 440L GuardShield PAC Type 4 Safety Light Curtain User Manual

Page 12

GuardShield™ PAC Safety Light Curtain Installation Instructions

10

Original instructions

The ANSI Safety Distance Formula

The ANSI safety distance formula, which is the Rockwell

Automation recommended formula, is as follows:

D

S

= K x (T

S

+ T

C

+ T

r

+ T

bm

) + D

pf

Ds

Minimum safety distance between the safe guarding

device and the nearest point of operation hazard, in

inches.

K

Hand speed constant in inches per second. The ANSI

standard value is 63 in. per second when the operator

begins reaching toward the point of operation hazard

from rest. NOTE: ANSI B11.19 1990 E4.2.3.3.5 states “The

value of the hand speed constant, K, has been

determined by various studies and although these

studies indicate speeds of 63 inches/second to over 100

in./second, they are not conclusive determinations. The

employer should consider all factors, including the

physical ability of the operator, when determining the

value of K to be used.”

Ts

Stop time of the machine tool measured at the final

control element.

Tc

Response time of the control system

Note:

T

s

and T

c

are usually measured by a stop time

measuring device.

Tr

Response time of the presence sensing device (safety

light curtain) and its interface, if any. This value is

generally stated by the device manufacturer or it can be

measured by the user.

Tbm

Additional time allowed for the brake monitor to

compensate for variations in normal stopping time.

Dpf

Depth penetration factor. It is an added distance to

allow for how far into the protective field an object, such

as a finger or hand, can travel before being detected. D

pf

is related to the safety light curtain’s object sensitivity.

Object sensitivity is the smallest diameter object which

will always be detected anywhere in the sensing field.

Example—Reach Over

In this example, the value of K is the hand speed constant of 63 in.

per second, the Ts machine stop time is 250 ms (0.250 sec), the

20% brake wear factor is 0.05 sec and the GuardShield PAC

response time is 20 ms (0.020 sec). The Dpf is 48 in. for reach over

applications.

IMPORTANT

The T

S

number must include the response

times of all devices, including the response

time of the safety light curtain, the safety light

curtain controller (if used), the machine’s

control circuit and any other devices that

react to stop the hazardous motion of the

machinery. Not including the response time

of a device or devices in the stop time

calculation will result in insufficient safety

distance for the application. This may result in

operator injury.

Ds= 63 in./sec X ( 0.250 + 0.050+ 0.02) + 48 in.

Ds = 20.16 in. + 48 in.

Ds = 68.16 in. from hazardous motion

The GuardShield three beam PAC should be mounted at least 68.2

in. from the closest reachable hazard point of the protected

machinery or equipment.

European Safety Distance Formula

A safety distance must be maintained between the light curtain

and the point of danger. This safety distance ensures that the

point of danger can only be reached after the dangerous state of

the machine has been completely removed.

The safety distance as defined in EN ISO 13855 and EN ISO 13857

depends on:

• Stopping/run-down time of the machine or system. (The

stopping/run-down time is shown in the machine

documentation or must be determined by taking a

measurement.)

• Response time of the protective device

• The person’s speed of approach

• Resolution of the light curtain and/or beam separation

When using the GuardShield PAC three beam with 400 mm beam

spacing, EN 999 requires that the first beam should be mounted

at 300 mm above the floor. When mounted in this configuration, it

is necessary to add 850 mm as the value for “C” in the safety

distance calculation equation.

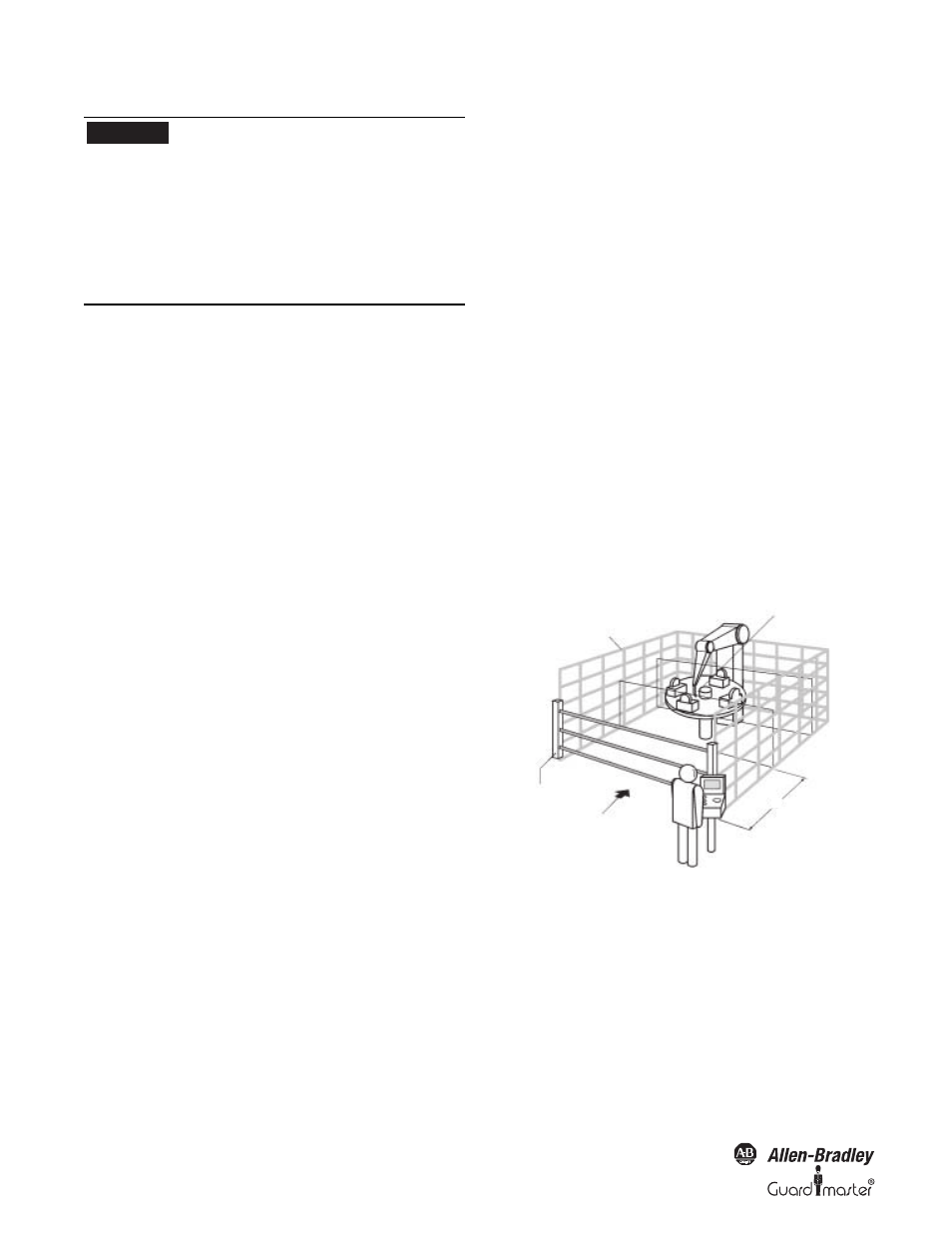

Figure 7: Safety distance from the point of danger