Configuring the smp-3 overload relay, Setting trip class – Rockwell Automation 193 193-5.0: Bulletin 913/592 SMP-3 Solid-State Overload Relay User Manual

Page 42

Chapter 3 – Installation and Wiring

3-32

CONFIGURING THE SMP-3 OVERLOAD RELAY

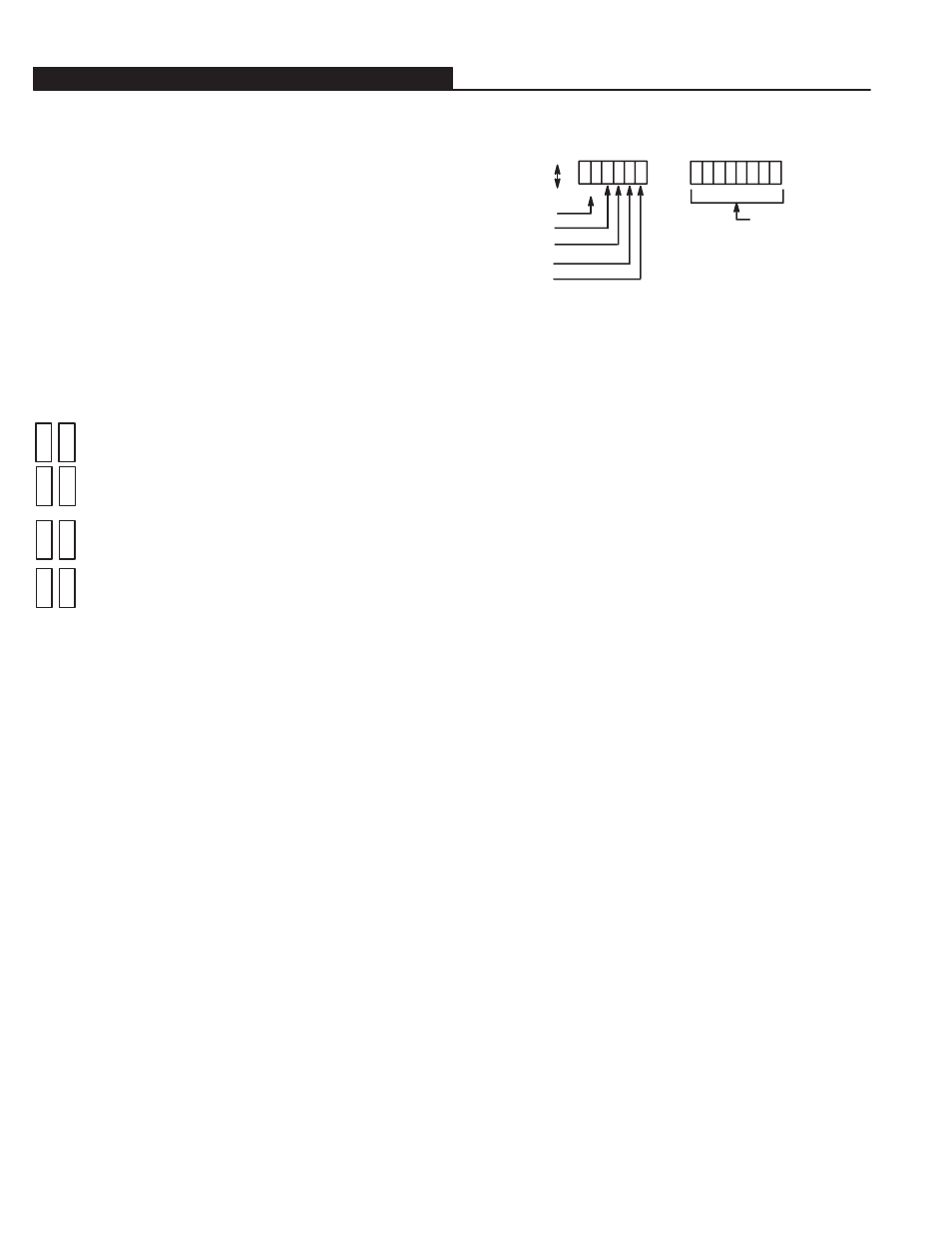

The SMP-3 overload relay contains 14 DIP switches for

configuring the trip characteristics of the SMP-3 overload relay.

These DIP switches are located on the front of the device under

the anti-tamper shield. These DIP switches are used to set the

trip class, manual or automatic reset mode, ground fault

detection, jam detection, test, and the full load current of the

SMP-3 overload relay as shown below:.

Setting Trip Class – The trip class can be set to class 10, 15, 20,

or 30. The trip class number (10, 15, 20, 30) defines the maxi-

mum time, in seconds, at which the relay will trip when carry-

ing 600% of the rated current. For the SMP-3 overload relay,

the rated current is 1.2 times the full load current (FLC) set-

ting.

Figure 3.32 SMP-3 DIP Switches

FLC Setting

Trip Class

Auto/Man

Ground Fault

Jam

Test

}

ON

OFF

Trip Class

DIPSwitch

• •

Class 10 – Place both Trip Class DIP switches in the “OFF” postion. (Class 10 is used for motor loads with low inertia

and for hermetically sealed motors with short locked rotor times that require the maximum protection.)

•

•

Class 15 – Place the most significant trip class DIP switch in the “OFF” position and the least significant in the “ON”

position. (Class 15 is used when the motor is not able to accelerate the load with a class 10 setting and the maximum

protection is needed.)

•

•

Class 20 – Place the most significant trip class DIP switch in the “ON” position and the least significant in the “OFF”

position. (Class 20 is standard overload protection for general applications.)

• •

Class 30 – Place both trip class DIP switches in the “ON” postion. (Class 30 is used for motors that need to start high

inertia loads and require long acceleration times.)