Installing input power wiring to the drive, Installing input power wiring to the drive -15, Table 2.b – Rockwell Automation 20L PowerFlex 700L Liquid-Cooled Adjustable Frequency AC Drive User Manual

Page 41

Frame 2 Installation

2-15

PowerFlex 700L Frames 2, 3A, and 3B Liquid-Cooled AC Drives User Manual

Installing Input Power Wiring to the Drive

Use the following steps to connect AC input power to the drive.

1. Connect the three-phase AC input power leads (three-wire 380-480V

AC) to the R/L1, S/L2, and T/L3 input power terminals on the Frame 2

drive.

For terminal locations, see

Figure 2.15

.

2. Tighten the AC input power terminal connections to the recommended

torque as shown in

Table 2.B Frame 2 Drive Power Terminal Specifications

!

ATTENTION: Do not route signal and control wiring with

power wiring in the same conduit. This can cause interference

with drive operation. Failure to observe this precaution can result

in damage to, or destruction of, the equipment.

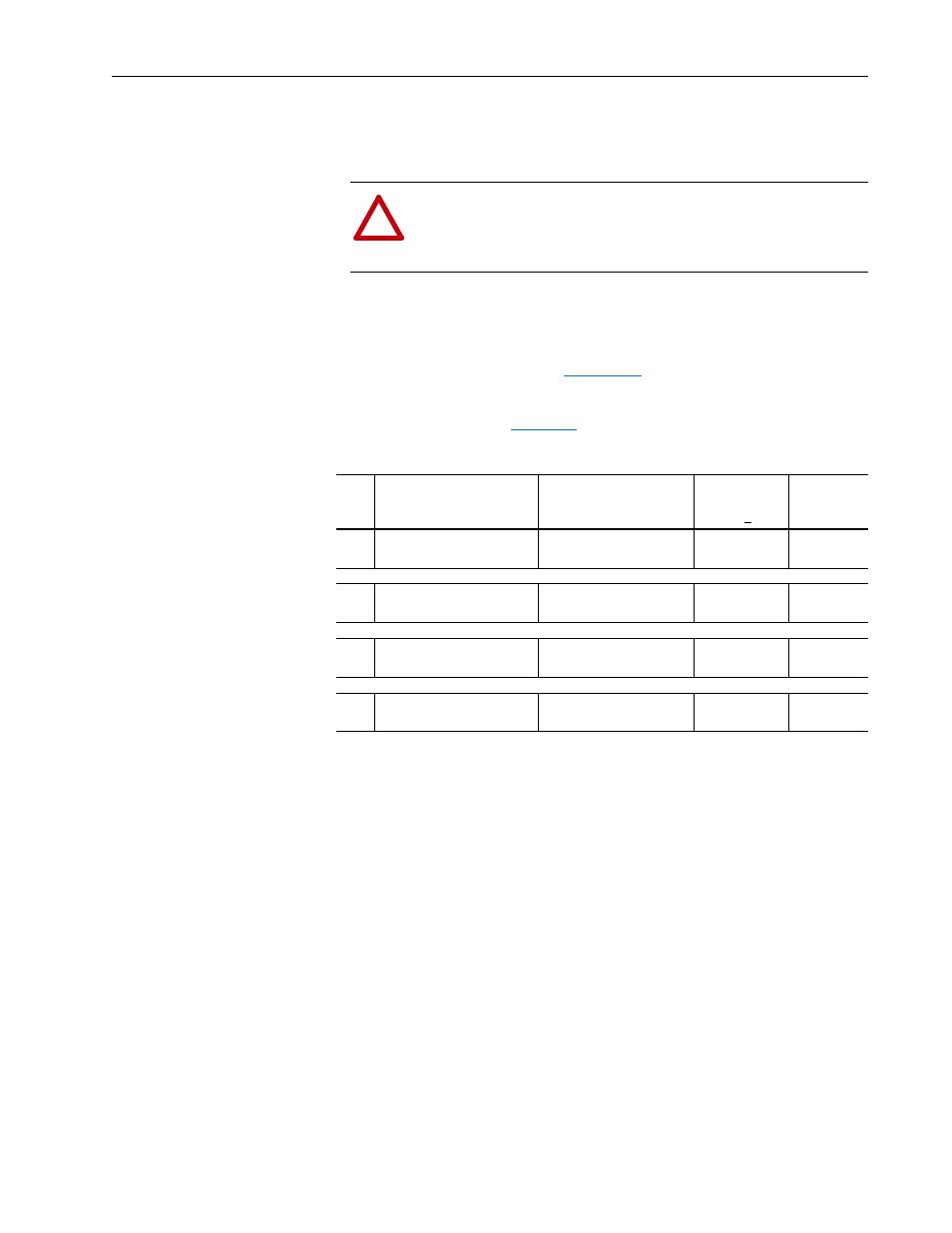

Item Name

Description

Recommended

Tightening

Torque (+10%)

Terminal

Bolt Size

(1)

(1)

Apply counter torque to the nut on the other side of terminations when tightening or loosening the terminal bolt to

avoid damage to the terminal.

➊

Input Power Bus Bar

(2)

R/L1, S/L2, T/L3

(2)

These connections are bus bar type terminations and require the use of lug connectors.

Input power

40 N

•m

(354 lb

•in)

M8

➋

Output Power Bus Bar

(2)

U/T1, V/T2, W/T3

Motor connections

40 N

•m

(354 lb

•in)

M8

➌

PE, Motor Ground Bus Bar

(2)

Terminating point for wiring

shields and grounds

40 N

•m

(354 lb

•in)

M8

➍

DC Bus Test Point Socket

(3)

(2 Terminals; DC+, DC-)

(3)

Use only to verify that DC bus capacitors are discharged before servicing the Power Module. No other external use

is permitted.

4 mm socket for DC bus

voltage measurement only

—

—