Packaging and mounting, 1336 force, Powerflex 700s – Rockwell Automation 1336T FORCE to PowerFlex 700S Phase II Drive Conversion Guide User Manual

Page 39

1336 FORCE™ To PowerFlex® 700S Phase II AC Drive Conversion Guide

39

Packaging and Mounting

1336 FORCE

• Small size conserves expensive panel space.

• “Planar Construction” eliminates most internal cables and connectors. Increases reliability.

• Laminar Bus Design reduces internal inductance, thereby reducing snubber losses and improving IGBT performance.

• Common Human Interface Module provides simplicity of programming and flexibility of operation.

• Thermal Dissipation Management design and extensive infra-red testing minimizes hot spots to maximize reliability.

• NEMA and International standards designed for global acceptability.

• Common AC/DC Bus accommodates both stand alone and common bus using standard Bulletin 2362 Motor Control

Center (MCC) vertical sections.

• Adapter Board Interface allows you to change the personality of the drive based on application.

PowerFlex 700S

• The innovative bookshelf design allows Zero Stacking™ or side-by-side mounting of the drives. With no minimum

spacing required between drives, valuable panel space is conserved and installation cost is reduced.

• The design of the PowerFlex® family of drives incorporates proven noise reduction components on both the input and

output of the drive. Many of the global EMC standards can be met and many noise related application concerns can be

reduced or eliminated using a standard “out-of-the-box” PowerFlex drive with no additional hardware or cost. By also

incorporating higher rated components and significant voltage suppression devices for both phase-to-phase and phase-

to-ground protection, power conditioning concerns and the need for additional hardware are significantly reduced.

• Pull-apart control terminal blocks for easy wiring and quick disconnect.

• Scalable hardware options include feedback and communications.

11

450

2

30.5 (100)

68.6 (225)

76.2 (250)

121.9 (400)

243.8 (800)

304.8 (1000)

1321-3R600-C

20

945

(3)

500

2

30.5 (100)

68.6 (225)

76.2 (250)

121.9 (400)

243.8 (800)

304.8 (1000)

1321-3R600-C

20

945

(3)

560

2

30.5 (100)

68.6 (225)

61.0 (200)

91.4 (300)

243.8 (800)

304.8 (1000)

1321-3R750-C

20

945

(3)

12

(1)

630

2

30.5 (100)

68.6 (225)

61.0 (200)

91.4 (300)

243.8 (800)

304.8 (1000)

2 X 1321-3RB400-C 40

480

(3)

710

2

30.5 (100)

68.6 (225)

61.0 (200)

91.4 (300)

243.8 (800)

304.8 (1000)

2 X 1321-3R500-C

40

645

(4)

800

2

30.5 (100)

68.6 (225)

61.0 (200)

91.4 (300)

243.8 (800)

304.8 (1000)

2 X 1321-3R500-C

40

645

(4)

13

900

(2)

2

30.5 (100)

68.6 (225)

61.0 (200)

91.4 (300)

243.8 (800)

304.8 (1000)

2 X 1321-3R600-C

40

645

(4)

1000

(2)

2

30.5 (100)

68.6 (225)

48.8 (160)

91.4 (300)

243.8 (800)

304.8 (1000)

2 X 1321-3R600-C

20

840

(5)

1100

(2)

2

30.5 (100)

68.6 (225)

48.8 (160)

91.4 (300)

243.8 (800)

304.8 (1000)

2 X 1321-3R750-C

20

840

(5)

(1)

Frame 12 drives have dual inverters and require two output reactors. The resistor ratings are per phase values for each reactor.

(2)

Some Frame 13 drives require two output reactors to match drive amp rating. The resistor ratings are per phase values for each reactor.

(3)

Resistor specification is based on two cables per phase.

(4)

Resistor specification is based on three cables per phase.

(5)

Resistor specification is based on four cables per phase.

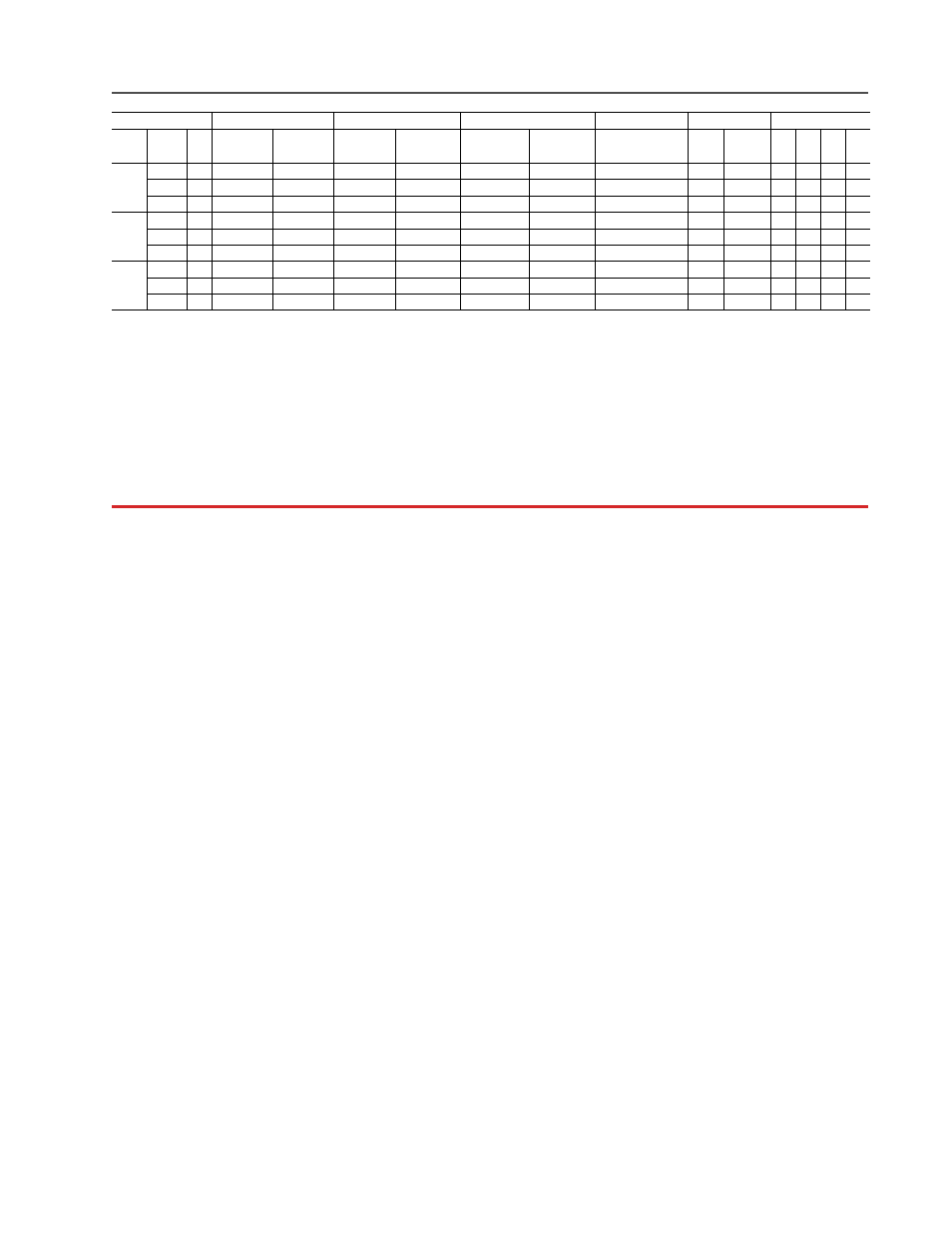

Drive

No Solution

Reactor Only

Reactor + Damping Resistor Reactor

Resistor

Available Options

Frame kW

kHz 1850V

2000V

1850V

2000V

1850V

2000V

Cat. No.

Ohms Watts

TF

A1

TF

B2

RW

R

2

RW

C