Brother ULT2002D User Manual

Page 303

9-8

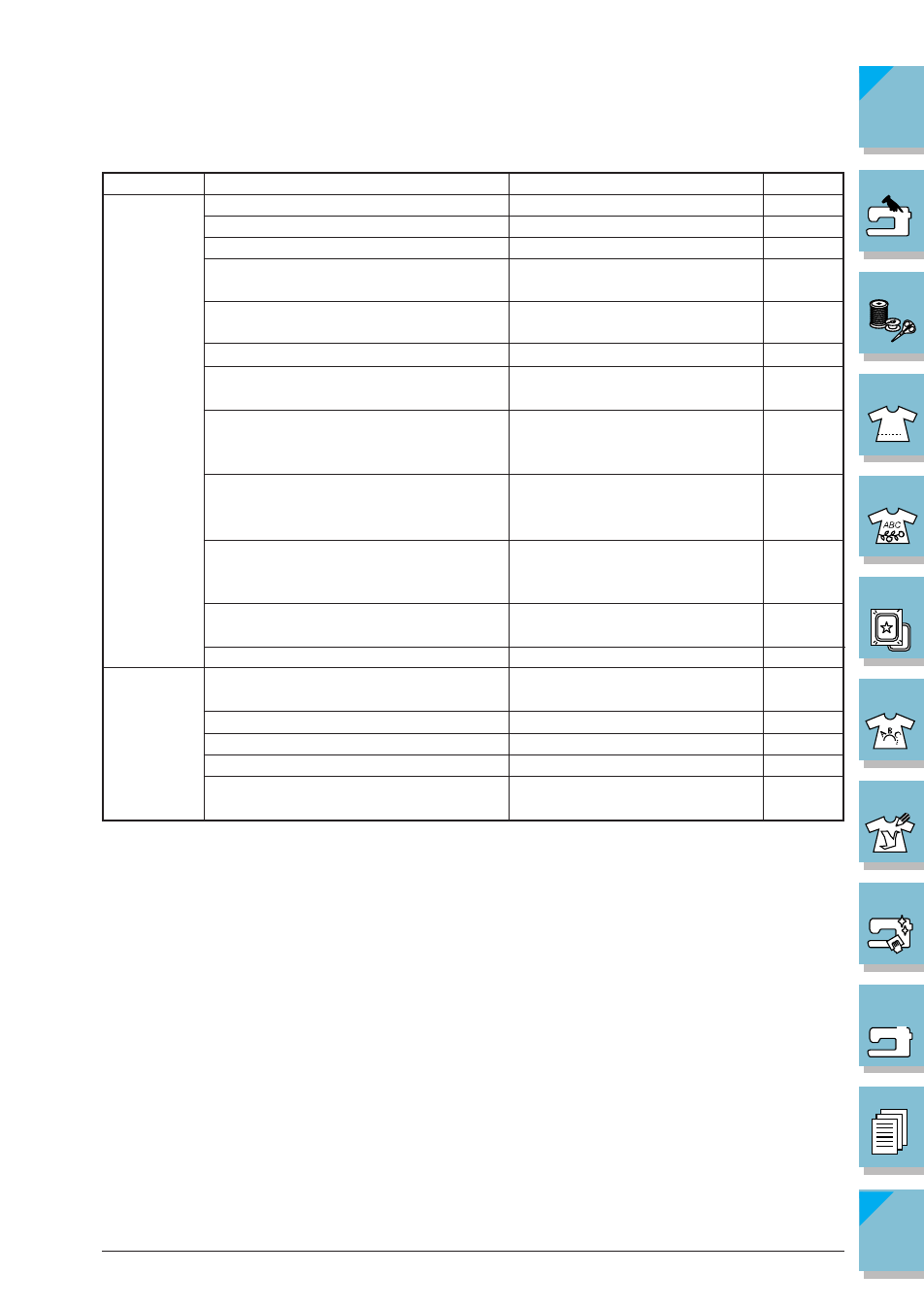

Troubleshooting

1 Needle is installed incorrectly.

2 Needle clamp screw is not tightened.

3 Needle is turned or bent.

4 Using improper needle or thread for the

selected fabric.

5 Wrong presser foot was used.

6 Upper thread tension is too strong.

7 Fabric is pulled during sewing.

8 Spool cap is set incorrectly.

9 There are scratches around the holes

in the needle plate.

0 There are scratches around the hole(s)

in the presser foot.

A There are scratches on the race.

B Needle is defective.

1 Feed dogs are set in the down position.

2 Stitches are too close together.

3 Wrong presser foot was used.

4 Needle is turned, bent or the point is dull.

5 Thread is entangled.

Problem

Cause

Page

Solution

Reinstall the needle correctly.

Tighten the needle clamp screw.

Replace the needle.

Check the “Fabric/Thread/Needle

Combination” chart.

Use the recommended presser

foot.

Adjust the thread tension setting.

Do not pull the fabric during sew-

ing.

Check the method for attaching the

spool cap, then reattach the spool

cap.

Replace the needle plate, or con-

sult your authorized dealer.

Replace the presser foot, or con-

sult your authorized dealer.

Replace the race, or consult your

authorized dealer .

Replace the needle.

Use the feed dog position lever to

raise the feed dogs.

Lengthen the stitch length setting.

Use the correct presser foot.

Replace the needle.

Cut the entangled thread and re-

move it from the race.

Fabric does

not feed

through the

machine

Needle

breaks

—