Steriflow SVC-SHC Series User Manual

Page 2

CSDT S

erieS

Compact Sanitary Disc Trap for Clean Environments

s

peciFicatiOns

Sizes:

1/2" (DN15) & 3/4" (DN20)

Ends:

Tri-Clamp

®

Materials

• Body: AISI 316L

• Disc Trap: AISI 316L

• Disc: AISI 316L

External Finish:

20 Ra mechanical finish

Pressure Maximum Allowable:

227 psig (16 kg/cm

2

)

Temperature Maximum Allowable:

842°F (450°C)

Maximum operating back pressure at the outlet should not

exceed 80% of the inlet.

Minimum differential pressure for satisfactory operation

3.6 psig.

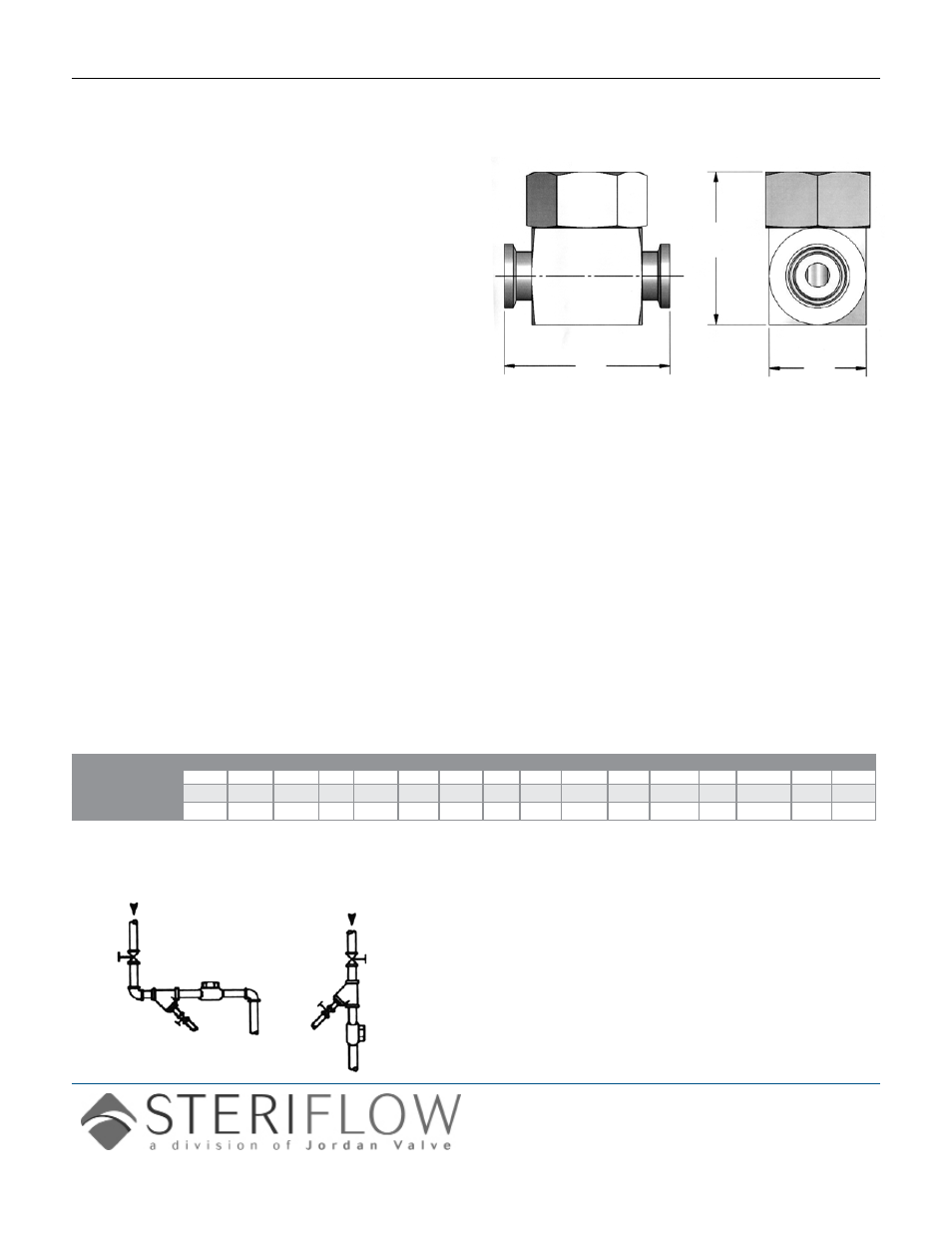

d

imensiOns

2.6

(65,0)

2.4

(59,9)

1.5

(38,1)

bar

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

psig

14

29

43

58

72

87

101 116 130

145

159

174

188

203

217

232

kg/hr

0

125

200

260 300 340

380

410 440 460

480

500

510

515

520

520

520

pph

0

275

440

572 660 748

836

902 968 1012 1056 1100 1122 1133 1144 1144 1144

The CSDT can be installed any position, but the preferred installation is in the horizontal plane with the

cap on top. As with all steam traps, isolation valves should be installed upstream and downstream of

the trap for safe maintenance. Always open isolation valves slowly until normal operating conditions are

achieved to avoid system shocks.

The CSDT Series can be maintained without disturbing the piping connections. Ensure that the trap is iso-

lated - upstream and downstream - before attempting to dismantle it. Allow the trap to cool before disman-

tling. Periodic cleaning of the disc and seat will facilitate trouble-free performance. Do not use corrosive

media for cleaning. Only the disc and seat are subject to wear. A worn disc can be replaced and slight

seat wear can be corrected by resurfacing with a lap plate.

From equipment

being drained

valve

strainer CSDT

strainer

(optional)

CSDT

valve

i

nstallatiOn

p

reventative

m

aintenance

CSDT/0611

Steriflow, a division of Jordan Valve

3170 Wasson Road • Cincinnati, OH 45209

513.533.5600 • 800.543.7311 • 513.871.0105 (f)

[email protected] • www.steriflowvalve.com

Steriflow Valve reserves the right to make revisions to its product, specifications, literature and related information without notice. Please visit our

website at www.steriflowvalve.com for the latest information on our products.

p

ressure

r

atings

r

ecOmmended

i

nstallatiOn