Steriflow Mark 9020 Series User Manual

Page 13

Size

A

2"

3.94 (100mm)

2-1/2"

3.94 (100mm)

3"

3.94 (100mm)

M

ark

9020 S

erieS

S

anitary

B

all

V

alVeS

-13-

t

ri

c

lamp

p

ressure

- t

emperature

r

atings

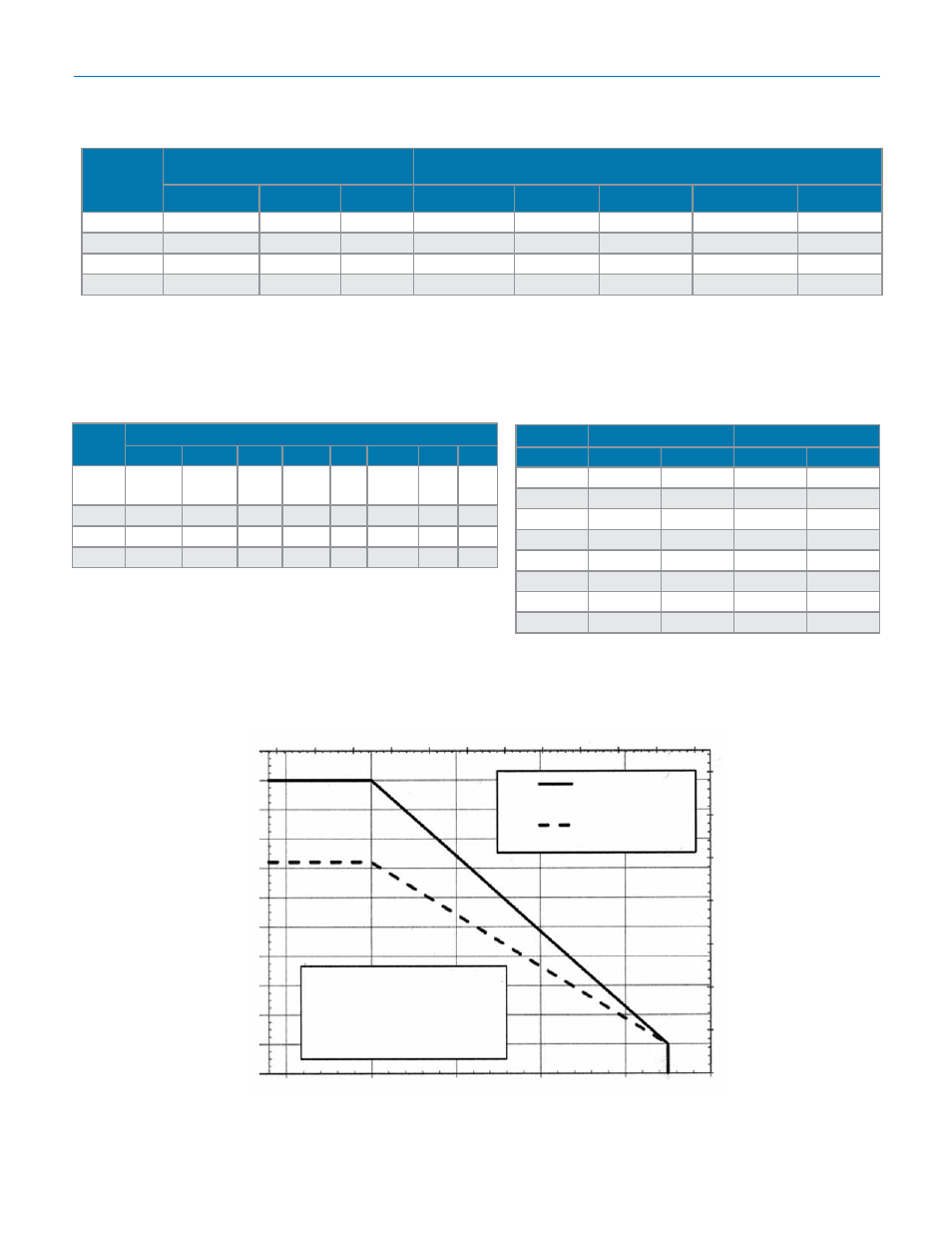

Temp °F

Pressure Rating, psi

13MHP Tri-Clamp (2 bolt)

Pressure Rating, psi

A13MHM Tri-Clamp (2-Segment Hinged, Wing Nut)

1/2"~2"

2-1/2"~3"

4"

1/2"~1-1/2"

2"

2-1/2"

3"

4"

-20

1000

720

720

500

450

400

350

300

0

1000

720

720

500

450

400

350

300

75

1000

720

720

500

450

400

350

300

250

1000

720

600

300

250

200

175

150

• Tri-Clamp gasket material maximum temperatures: Buna-N, PTFE – 200°F; EPDM – 300°F; Viton — 400°F;

Silicon — 450°F

• Pressure ratings based on tri-clamp and maximum pressure rating for product.

t

uBe

p

ressure

- t

emperature

r

atings

t

echnical

i

nFormation

Temp

°F

Pressure Rating, 2" ~ 4" Tube End, psi

1/2"

3/4"

1" 1-1/2" 2" 2-1/2" 3"

4"

-20 to

+300 >1000 >1000 1000 1000 720 695

525 505

350

>1000 >1000 1000 1000 720 610

510 485

400

>1000 >1000 1000 995 720 590

480 470

450

>1000 >1000 1000 960 715 570

470 450

Size

Operating Torque*

Flow Coefficient

NPS

in-lb

N.m

Cv

Kv

1/2"

39

4,4

8

6,9

3/4"

95

10,7

30

26

1"

148

16,7

65

56

1-1/2"

338

38

190

163

2"

651

74

435

374

2-1/2"

797

90

720

619

3"

974

110

1120

963

4"

1328

150

2100

1806

p

ressure

- t

emperature

c

hart

1000

900

800

700

600

500

400

300

200

100

0

0

100

200

300

400

500

1/2"~2"

2-1/2"~4"

Temperature °F

Pressure, psi

Graph shows body center rating.

Clamp fittings or tube ends may

have lower allowable pressure

and temperature values than

center section

* TFM 1600 seats, maximum differential pressure

Tube ratings based on ASME B31.3 – 2002 for 316L tubing

and on maximum pressure rating for the valve

1100

-25

0

25

50

75 100 125 150 175 200 225 250

0

10

20

40

30

50

60

70

Pressure, bar

Temperature °C