Steriflow Mark 9030 Series User Manual

Page 11

M

ark

9030 S

erieS

S

anitary

B

all

V

alVeS

-11-

t

echnical

i

nFormation

Size

Operating Torque*

Flow Coefficient

NPS

DN

in-lb

N.m

Cv

Kv

Straight (Run)

90°

(Branch)

Straight

(Run)

90°

(Branch)

1/2"

DN15

49

55

4.6

2,6

3.7

2,3

3/4"

DN20

104

11,8

12.3

7,7

10.6

6,6

1"

DN25

243

27,5

25

15,7

21.6

13,5

1-1/2"

DN40

408

46,1

65

41

56

35

2"

DN50

958

108

126

80

108

69

2-1/2"

DN65

207

132

178

113

3"

DN80

1476

167

310

194

267

166

4"

DN100

582

345

501

297

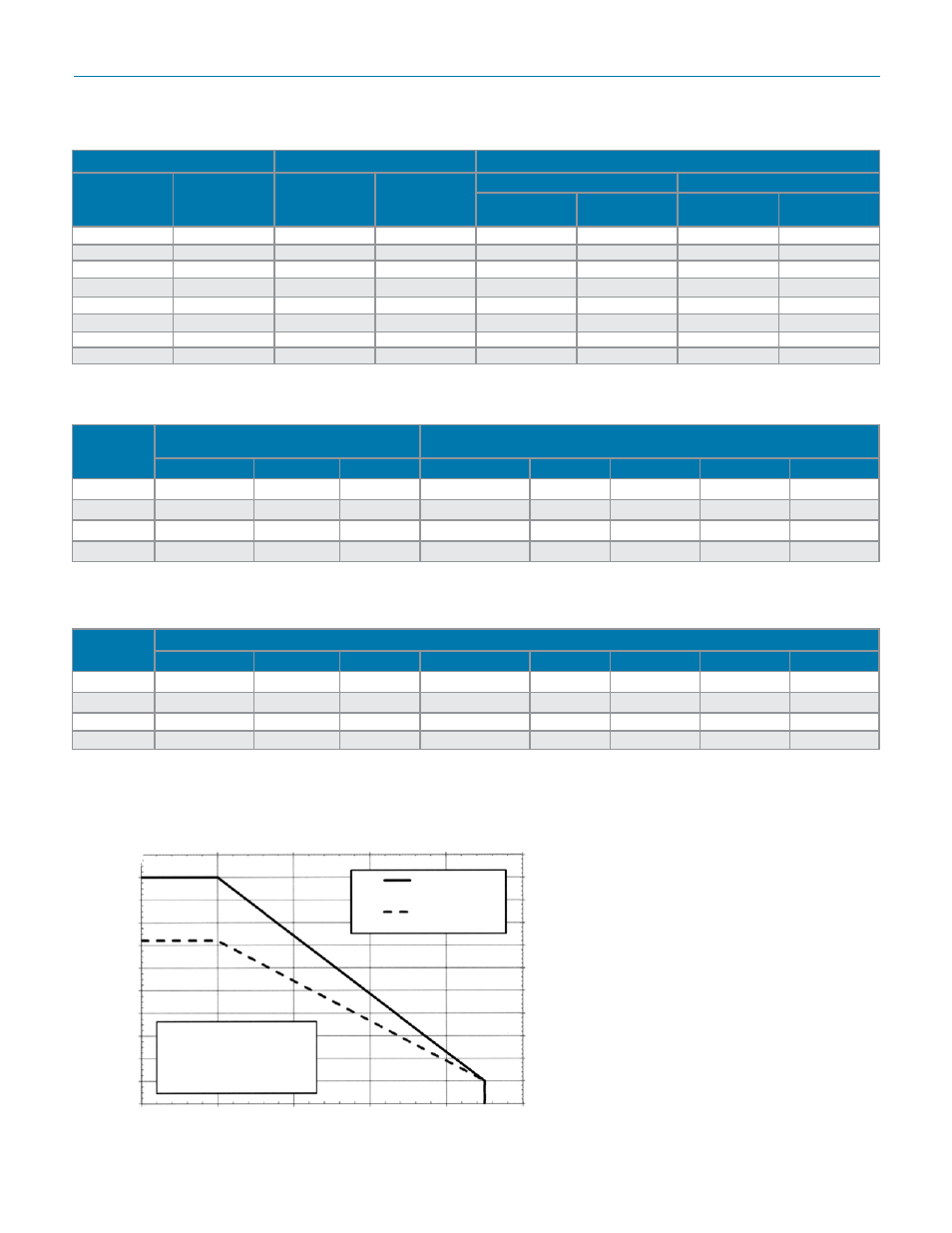

p

ressure

- t

emperature

c

hart

1000

900

800

700

600

500

400

300

200

100

0

0

100

200

300

400

500

1/2"~ 2"

DN15-DN40

2-1/2"~ 4"

DN50-DN100

Temperature °F

Pressure, psi

Graph shows body center

rating. Clamp fittings or tube

ends may have lower allowable

pressure and temperature

values than center section

1100

* TFM 1600 seats, maximum differential pressure

Temp °F

Pressure Rating, psi

13MHP Tri-Clamp (2 bolt)

Pressure Rating, psi

A13MHM Tri-Clamp (2-Segment Hinged, Wing Nut)

1/2" ~ 1-1/2"

2" ~ 3"

4"

1/2" ~ 1-1/2"

2"

2-1/2"

3"

4"

-20

1500

1000

800

500

450

400

350

300

0

1500

1000

800

500

450

400

350

300

75

1500

1000

800

500

450

400

350

300

250

1200

800

600

300

250

200

175

150

Tri-clamp gasket material maximum temperatures: Buna-N, PTFE – 200°F; EPDM – 300°F; Viton – 400°F; Silicon – 450°F

t

ri

-c

lamp

p

ressure

– t

emperature

r

atings

Temp °F

Pressure Rating, 2" – 4" Tube End, psi

1/2"

3/4"

1"

1-1/2"

2"

2-1/2"

3"

4"

-20 – +300

>2000

>2000

1635

1070

795

695

525

505

350

>2000

>2000

1575

1035

770

610

510

485

400

>2000

>2000

1575

995

740

590

480

470

450

>2000

>2000

1465

960

715

570

470

450

t

uBe

p

ressure

– t

emperature

r

atings

Tube ratings based on ASME B31.2 – 2002 for 316L tubing

-18

38

93

149

204

260

Seat Tightness Note: If closed port

pressure exceeds open port pressure,

the ball may be forced slightly off the

seat, which would allow mixing from all

ports. Occurrence may vary depending

upon flow and ambient conditions.

76

69

55

48

41

34

28

21

14

62

7

0

Pressure, bar

Temperature °C