Specifications, Hart, Protocol – Steriflow Mark 16IQ Series User Manual

Page 3

Mark 16IQ Smart Valve Positioners

Specifications

-3-

Input:

•

Signal Range: 2 wire circuit ~ 4-20 mA; 3/4 wire cir-

cuit ~ 0 / 4-20 mA

•

Load Voltage: 2 wire circuit ~ > 11V with HART; > 10

V without HART

•

Auxiliary Voltage: 3/4 wire circuit ~ 18 - 30 V

Output:

Up to full air supply pressure

Pneumatic System:

•

Air Supply Pressure: 45 psig max for Steriflow Valve

actuators)

•

Air Capacity: > 5.3 scfm; adjustable

•

Standard Consumption: 0.02 scfm independent of

air supply pressure

Optional Gauge Block:

delivered with two gauges for in-

put air supply and positioning pressure

Control Data:

•

Sensing Time A/D Converter: 12.5 ms

•

Resolution A/D Converter: <0.05%

•

Transmission Error A/D Converter: <0.2%

•

Dead Band Controller: adaptive or adjustable, 0.1-

10%

•

Setting Time Controller: 1.5 - 150

Ambient Temperature:

-20 to +175°F

Shock Resistance:

10g

Connections:

•

Pneumatic: 1/4" NPT

•

Electric: screwed terminals max. 1.5mm2, cable

union size PG 13

Protection Class:

IP 65/NEMA 4X

Weight:

2.86 pounds

Hazardous Location Approvals:

•

Basic unit: none

•

Standard HART

®

protocol unit:

—

FM/CSA: (IS) Class I, Div. 1, Groups ABCD, T6/

T5/T4

–

NEC 505: Class I, Zone 2 Group IIC T6/

T5/T4.

–

NEC 500: Class I, Div 2 Group IIC T6/T5/

T4.

—

EU: II 2G EEx ia/ib IIC T6/T5/T4

•

For explosion proof installations (i.e. (XP) Class I,

Div. 1), please contact factory for options.

With the HART

®

option comprehensive sets of mainte-

nance and diagnostic data can be called up directly at

the positioner itself:

•

zero point and range

•

actuating speed

•

original & current stats

—

Actuator leakage

—

Operating hours

—

Min/max temperatures

—

Valve limit position (i.e. change of stroke length

due to seat wear)

•

dead band in both directions

•

number of alarm reports

•

number of directional changes

•

total travel

In addition, you may call up data about the controlled ac-

tuator:

•

instrument number

•

type of actuator

•

operating mode

•

process data

•

parameter data

With the SIPROM PS2 Software interface, the current

maintenance data can be remotely compared with previ-

ous information to quickly detect any deviations so that

corrective action can be taken. And, actuator and valve

problems can be caught early to allow ample time to

schedule repairs.

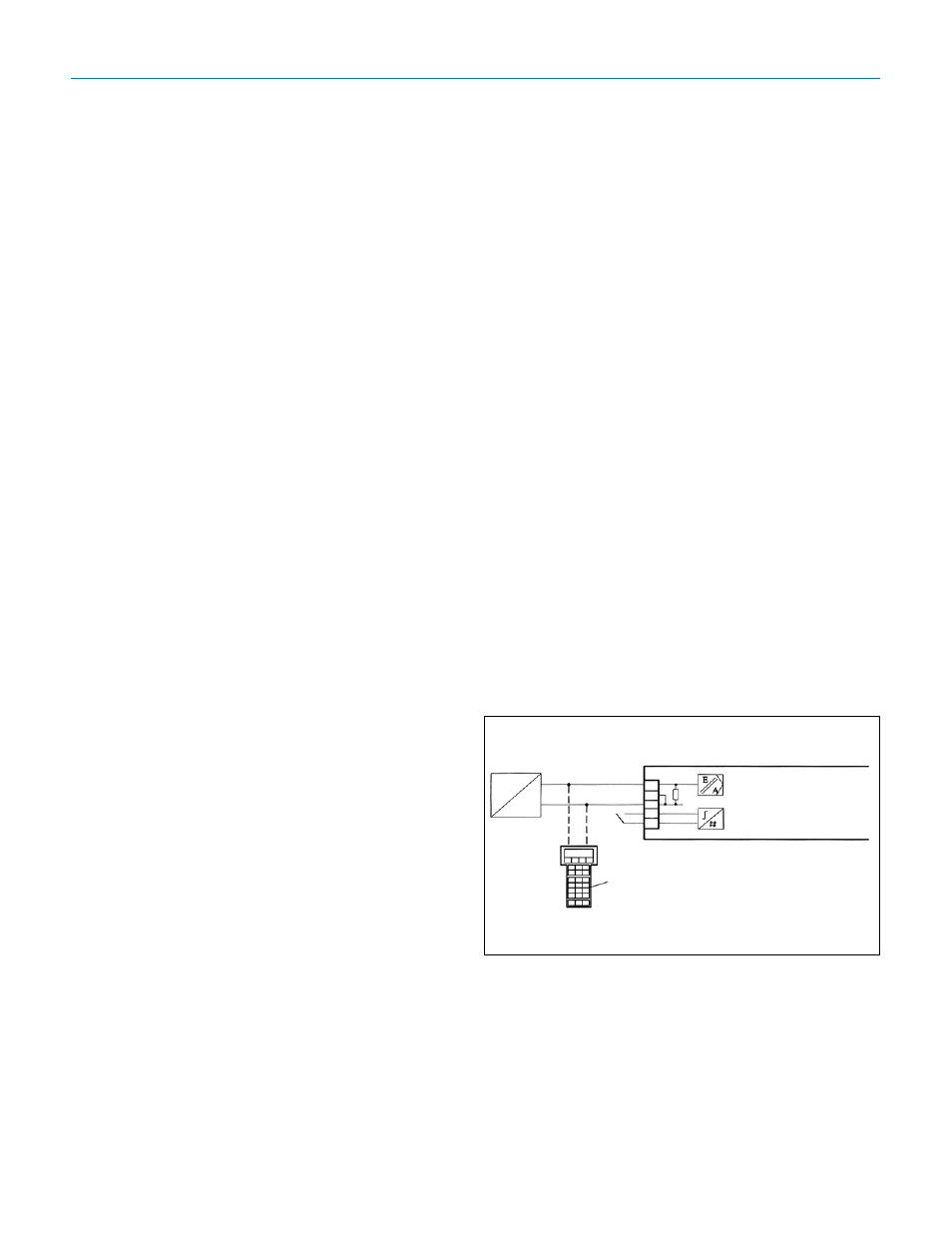

HART

®

Protocol

Positioner

Digital Input 1

HART Communicator

J

Two-Wire Connection

+ 4 to 20 mA

How to Order

1. See Mark 978 Control Valve order grids

2. Select the appropriate base valve model. See mod-

els Mark978SP or NSP for an Inline valve. (Sp for Side

Mounted Positioner).

3. Select the specific positioner you want in the last digit

of the MK978 model number. Choices are available

for HART

®

, Foundation Fieldbus

TM

, models.