Steriflow Mark 95AA Series User Manual

Page 2

M

ark

95aa S

erieS

S

anitary

a

ir

a

ugMented

B

ack

P

reSSure

r

egulatorS

-2-

Sizes:

1/2" (DN15), 3/4" (DN20), 1" (DN25), 1-1/2"

(DN40), 2" (DN50), 3" (DN80)

End Connections

• Quick disconnect fittings (

to match Tri-Clamp®

fitting)

• DIN/ISO sanitary connections

Body & Trim Materials:

316L Stainless Steel (ASTM

A47, S31603)

Seat Materials

• Optional soft seat (for Cv 1.5, 1" size and above)

– Jorlon (FDA & USP Class VI) for steam and hot

fluid service to 338°F (170°C)

– PEEK (FDA & USP Class VI) for steam and hot

fluid service to 350° (177°C)

–

PTFE to +252°F (122°C) continuous or 275°F

(135°C) intermittent [not to exceed 15 min. in a one

hour period]

FDA, USP Class VI

Note: consult factory for 1/2" & 3/4" soft seat materials

Spring Housing Materials

• CF8M cast SST (1/2" – 1-1/2")

• Fabricated 316L SST (2" – 3")

Diaphragm Materials

• EPDM/Nylon (to 275°F, 135°C) – FDA only

• Jorlon (to 400°F, 204°C) – FDA, USP Class VI

• Ulta-thin Jorlon (to 400°F, 204°C), FDA, USP

Class VI (for use with 3-8 range spring only)

O-Ring Materials

• EPDM (to 275°F, 135°C) - FDA, USP Class VI

• Buna-N (to 225°F, 107°C) - FDA

• Viton (to 400°F, 204°C) - FDA, USP Class VI

• Silicone (to 400°F, 204°C) - FDA, USP Class VI

• Teflon-Encapsulated Viton (to 400°F, 204°C) -

FDA, USP Class VI

• Teflon-Encapsulated Silicone (to 400°F, 204°C) -

FDA, USP Class VI (1-1/2" - 3")

Shutoff:

Class VI soft seat; Class III hard seat

Body Pressure Temperature Rating:

(dependent

upon construction)

Pressure on 1/2", 3/4" & 1" size limited to 225 psig (15,5 bar)

@ 100°F and 200 psig (13,8 bar) @ 400°F if using Ultra-thin

Jorlon diaphragm.

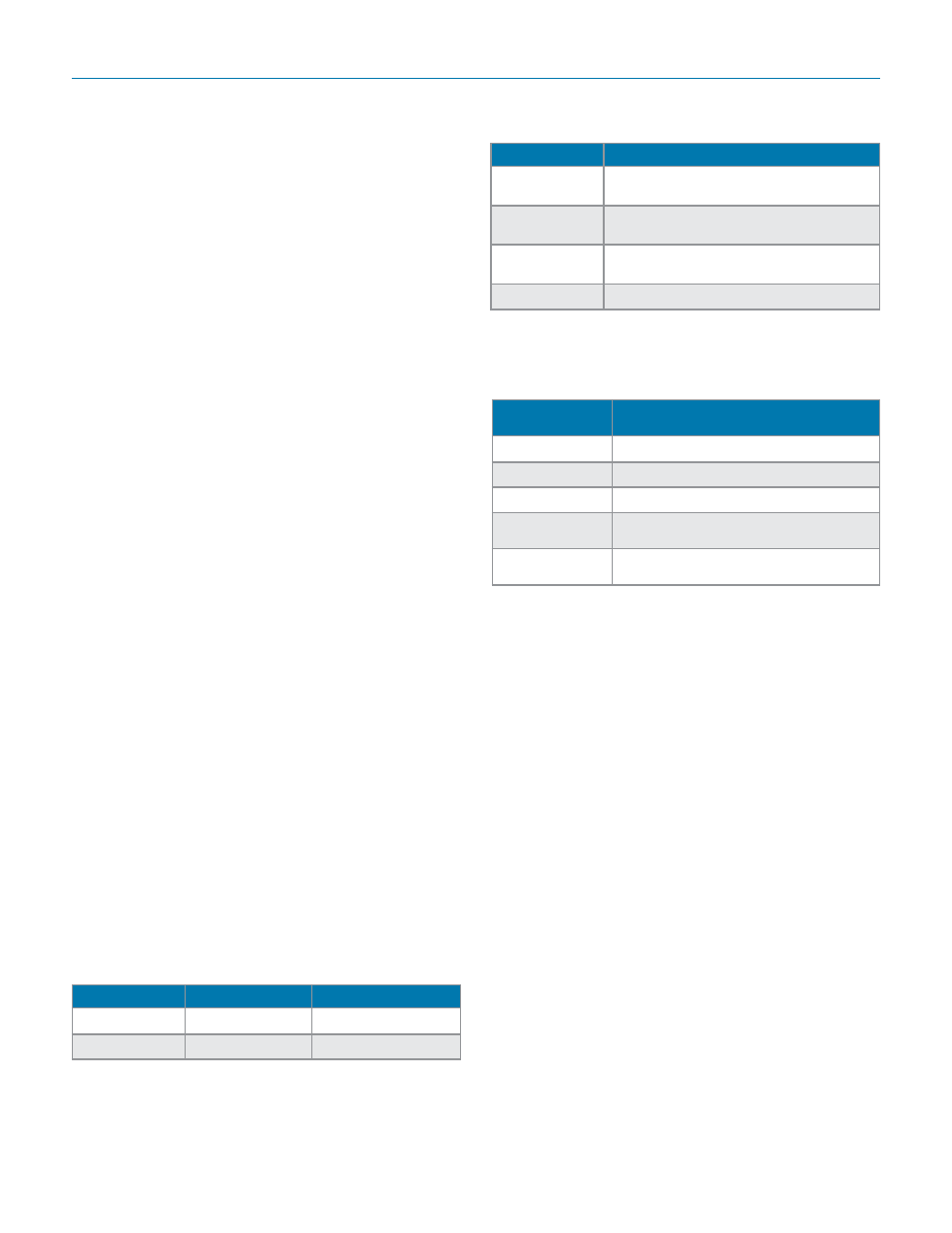

Valve Size

PSIG @ 100°F

PSIG @ 450°F

1/2", 3/4" & 1"

350 (24,1 bar)

250 (17,2 bar)

1-1/2" , 2" & 3"

200 (13,8 bar)

200 (13,8 bar)

Valve Size

Set Point Ranges, PSI (bar)

1/2", 3/4" & 1"

3-8* (0,2-0,5), 5-30 (0,3-2,1),

15-50 (1,0-3,4), or 35-90 (2,4-6,2)

1-1/2"

3-25* (0,2-1,7), 10-25 (0,7-1,7),

15-40 (1,0-2,8) or 35-85 (2,4-5,9)

2"

5-25* (0,3-1,7), 10-25 (0,7-1,7)

or 15-60 (1,0-4,1)

3"

15-25 (1,0-1,7) or 15-60 (1,0-4,1)

* Range available with elastomer or Ultra-thin Jorlon

diaphragm only. Maximum pressure drop 40 psi

.

Set Point Spring Ranges

Cv (Kv) Ratings:

Valve Size

Elastomer & Jorlon Diaphragms

Cvs (Kvs)

1/2", 3/4"**

0.5 (04,), 1.5 (1,3)

1"**

1.5 (1,3), 3.0 (2,6) or 5.5 (4,7)

1-1/2"

4.5 (3,9) or 10.0 (8,6)

2"

10.0 (8,6) or

19.0 (16,3)

3"

10.0 (8,6) or

28.0 (24,1)

Maximum Allowable Pressure Differential:

200 psi

(3-8 spring range has a max of 40 psi)

Maximum Allowable Pressure Setpoint:

The total

of the spring setpoint and additional air pressure can-

not exceed:

• 3/4" – 1": 135 psi (9,3 bar)

• 1-1/2": 100 psi (6,9 bar)

• 2" – 3": 80 psi (5,5 bar)

Minimum Allowable Differential Pressure:

No

restrictions

Minimum Allowable Setpoint:

Equivalent to the

minimum spring rate set point:

• 3/4" – 1": 2 psi (0,14 bar)

• 1-1/2": 3 psi (0,21 bar)

• 2": 5 psi (0,34 bar)

Surface Finish:

Refer to MK95 data sheet

** Cv's limited when using the 3-8 range spring