Steriflow Mark 96 Series User Manual

Page 2

M

ark

96 S

erieS

S

anitary

P

reSSure

r

egulatorS

s

peciFications

– o-r

ing

D

iaphragm

Sizes:

3/4" (DN20), 1" (DN25), 1-1/2" (DN40), 2"

(DN50), 3" (DN80)

End Connections

• Quick disconnect fittings (

to match Tri-Clamp®

fitting)

• DIN/ISO sanitary connections

Body Connections:

Mark 96 – Bolted – Standard for

all sizes

Body & Trim Materials:

316L Stainless Steel (ASTM

A479)

Seat Materials

• Standard hard seat – integral 316L SST seat

• Optional soft seat

– Jorlon (for Cv 1.5, 1" size and above) (FDA &

USP Class VI) for steam and hot fluid service to

338°F (170°C)

– Teflon (for Cv 2.5, 1" size and above) to 252°F

(122°C) continuous or 275°F (135°C) intermittent

[not to exceed 15 min. in a one hour period] FDA,

USP Class VI

– PEEK (3/4" and above) (FDA & USP Class VI)

for steam and hot fluid service to 350° (177°C)

Note: consult factory for how to order PEEK soft seat

materials

Spring Housing Materials

• CF8M cast SST (3/4" – 1")

• Fabricated 316L SST (1-1/2" – 3")

Diaphragm Materials

• 316L SST

• EPDM/Nylon (to 275°F, 135°C), FDA only

• Jorlon (to 400°F, 204°C) – FDA, USP Class VI

• Ulta-thin Jorlon (to 400°F, 204°C), FDA, USP

Class VI (for use with 3-8 range spring only)

O-Ring Materials

• EPDM (to 275°F, 135°C) – FDA, USP Class VI

• Buna-N (to 225°F, 107°C) – FDA

• Viton (to 400°F, 204°C) – FDA, USP Class VI

• Silicone (to 400°F, 204°C) – FDA, USP Class VI

• Teflon-Encapsulated Viton (to 400°F, 204°C) –

FDA, USP Class VI (1-1/2" - 3" only)

• Teflon-Encapsulated Silicone (to 400°F, 204°C) –

FDA, USP Class VI

Shutoff:

ANSI Class III hard seat or Class VI soft seat

-2-

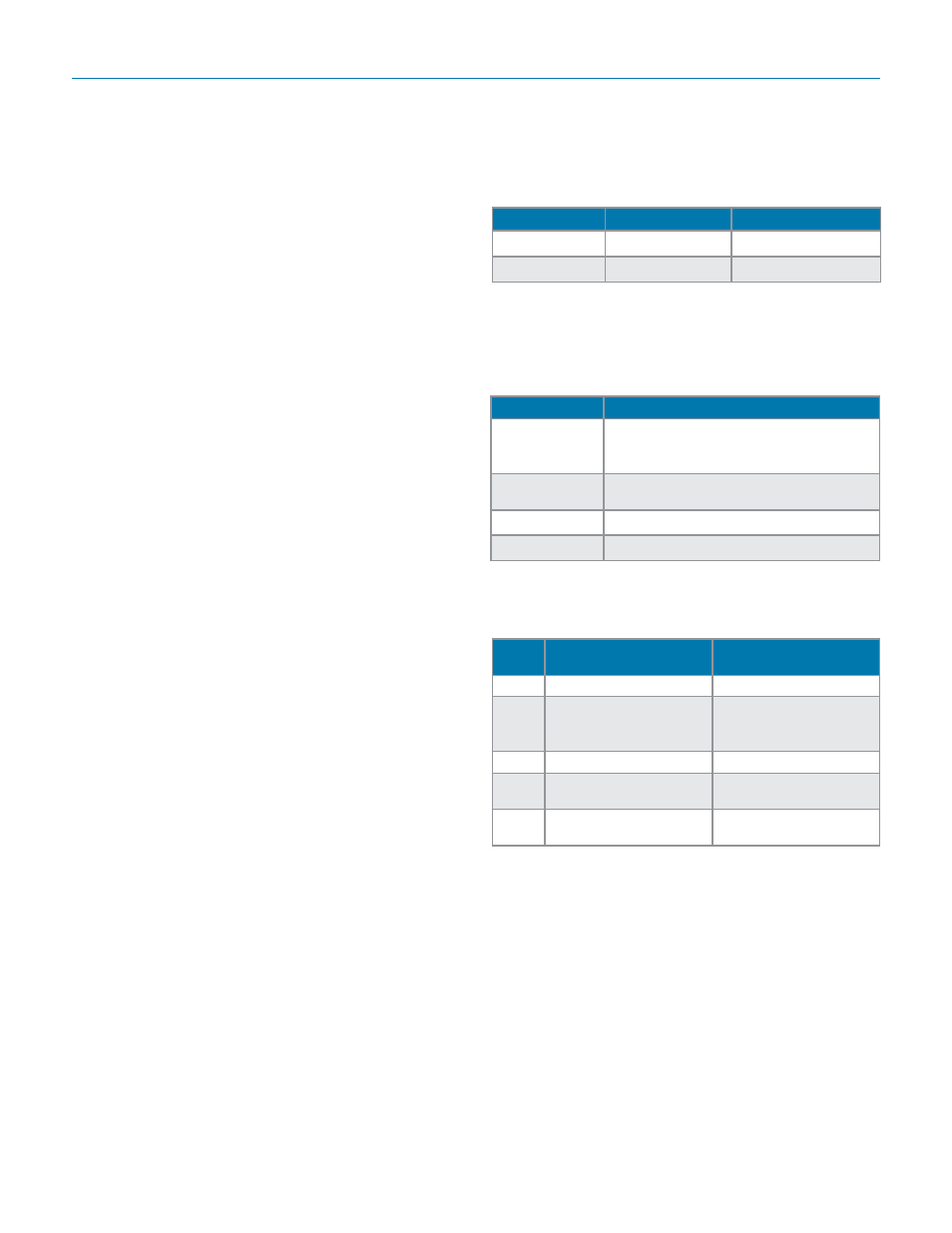

Valve Size

PSIG @ 100°F

PSIG @ 450°F

3/4" & 1"

350 (24,1 bar)

250 (17,2 bar)

1-1/2" , 2", & 3" 200 (13,8 bar)

200 (13,8 bar)

Note: for 1/2" size, refer to our Mark 96C datasheet

Valve Size

Set Point Ranges, PSI (bar)

3/4" & 1"

3-8* (0,2-0,5), 5-25 (0,37-1,7), 15-50

(1,0-3,4), 40-90 (2,7-6,2), or 75-135

(5,2-9,3)

1-1/2"

10-25 (0,7-1,7), 15-50 (1,0-3,4) or

35-100 (2,4-6,9)

2"

10-25 (0,7-1,7) or 15-60 (1,0-4,1)

3"

15-25 (1,0-1,7) or 15-60 (1,0-4,1)

* Range available with elastomer or Ultra-thin Jorlon

diaphragm only. Maximum pressure drop 40 psi

.

Set Point Spring Ranges

Cv (Kv) Ratings:

Valve

Size

Available Cv (Kv)

Cv for Relief Valve

Sizing

3/4"***

1.5 (1,3)

3.8 (3,27)

1"***

1.5, 2.5, 4.5, 5.5**,

6.1**

(1,3; 2,2; 3,9; 4,7; 5,3)

10.7 (9,2)

1-1/2" 4.5 or 10.0 (3,9 or 8,6) 6.7 (5,76); 26.3 (22,6)

2"

10.0 or 19.0 (8,6 or

16,3)

16.5 (14,2), 56.5 (48,6)

3"

10.0 or 23.0 (8,6 or

19,8)

16.5 (14,2); 67.1 (57,7)

** Not available with metal diaphragms, Jorlon and other

elastomers acceptable

*** When using the 3-8 range spring the following sizing limits apply:

Maximum Allowable Pressure Differential:

200 psi

(3-8 spring range has a max of 40 psi)

Body Pressure Temperature Rating:

(dependent

upon construction)

Pressure on 1/2", 3/4" & 1" size limited to 225 psig (15,5 bar)

@ 100°F and 200 psig (13,8 bar) @ 400°F if using Ultra-thin

Jorlon diaphragm.

Set Point

Sizing Limit (of rated capacity)

8

50%

5

33%

3

25%

For example a 1" Cv5.5 valve with a 3-8 range spring, if the

customer’s set point is P2 = 8 psi, then the actual Cv sizing

should not exceed 2.75Cv. If the customer’s intended set

point is P2 = 5 psi, then the actual Cv sizing should not exceed

1.8Cv and if their set point is P2 = 3 psi, then the actual Cv siz-

ing should not exceed 1.38 Cv.