D. transporter adjustment procedures – MacDon Double Windrow Attachment User Manual

Page 19

SECTION UA – UNLOADING AND SETUP

Form 169365

UA-5

Issue – May 2008

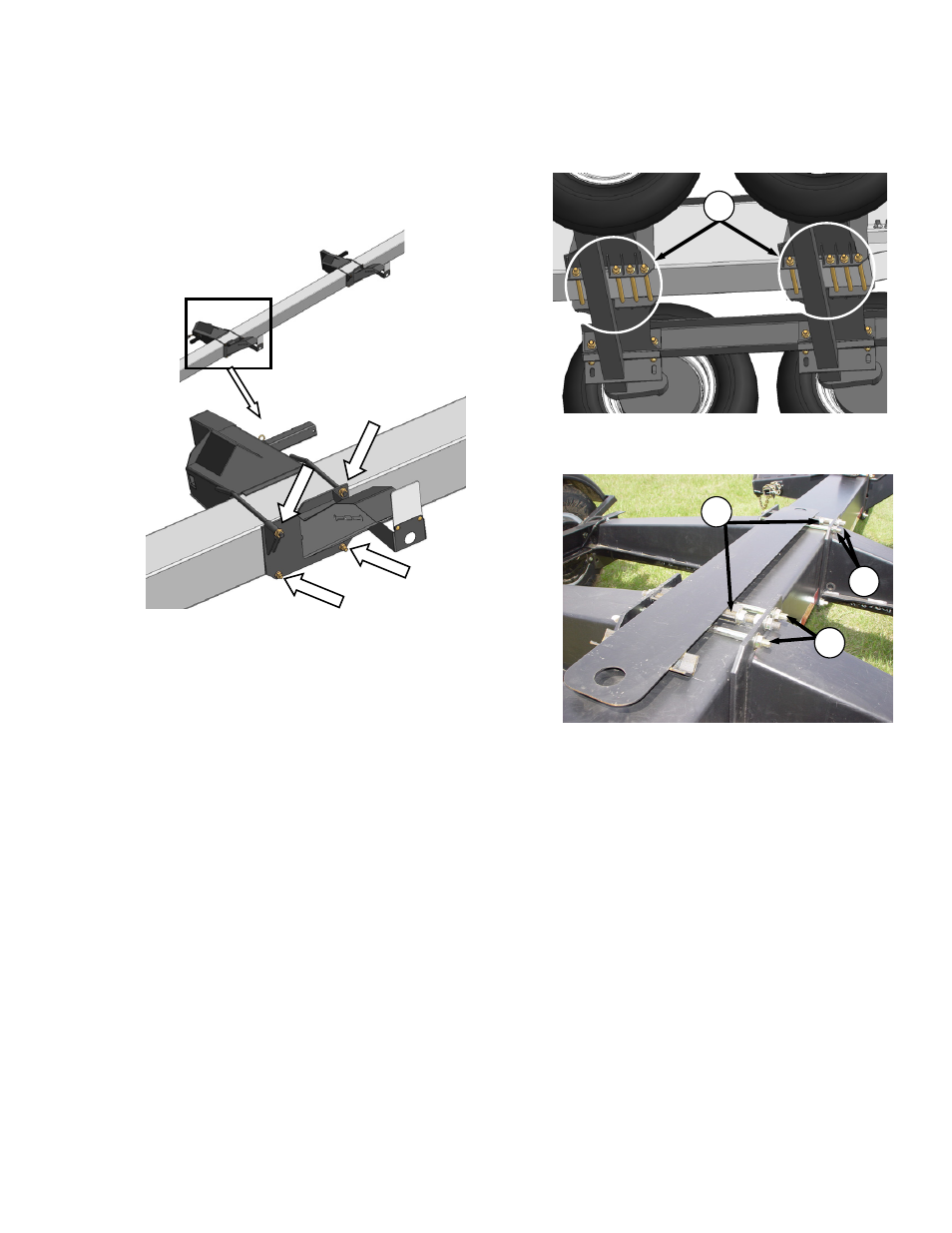

D. TRANSPORTER ADJUSTMENT

PROCEDURES

I. CUTTERBAR SUPPORTS

a. Loosen four nuts on each support.

b. Slide both supports to specified location (see

previous page).

NOTE

Supports are joined by a tie angle and

move together to maintain correct

spacing.

c. Re-tighten nuts. Ensure supports are evenly

clamped onto main beam.

II. MOVING REAR AXLES

Two & Three Axle Transporter Only

a. Loosen four lower bolts (A) on each axle

support.

b. Loosen two bolts (B) on each axle support

topside.

c. Loosen outer nuts on both adjuster rods (C).

d. Turn inner nuts on both adjuster rods (C) so that

left and right frames separate approximately 3

mm from main beam.

e. Slide tandem axle assembly to desired location.

Holes are provided on adjuster plate for

attaching a winch or come-along.

NOTE

Ensure winch pulls adjuster plate straight

to avoid binding.

f. Tighten inner nuts on adjuster rods (C) against

adjuster plate.

g. Retighten all nuts and bolts. Ensure supports

are evenly clamped onto main beam.

A

B

B

C