MTS SWIFT 50 GLP Sensor User Manual

Page 40

SWIFT 50 GLP Sensors Installation

40

Road and Track Vehicles

Installing the Transducer

C.

Make sure that the covers on the shunt connectors are in place and

secure.

Press the covers over the shunt connector. Secure the covers by

tightening the two SST 10-32 UNF screws (one for each cover), using

an M4 or 5/32 inch hex key wrench, to 3.8 N•m (2.8 ft-lbf).

5. For dual rim configurations (see the next figure): Attach the extension

assembly and slip-ring bracket with slip ring to the transducer.

A.

Thread the standoffs, with the M12 threaded studs, into the four M12

threaded holes in the face of the transducer.

Lubricate the threads on each threaded stud with Molykote g-n paste

and torque to 93 N•m (69 lbf•ft).

B.

Attach the four extension brackets to the top plate using the M5 X 10

mm long fasteners provided (2 fasteners each).

Orient the short side of the dovetail on the connector toward the center

of the top plate.

Lubricate each fastener with Molykote g-n paste and torque each to 6.5

N•m (58 lbf•in).

C.

Place the top plate, with extensions attached, over the standoffs.

Orient the top plate such that the Board A extension (see the labeling

on the top plate) is aligned with the Board A connector on the

transducer.

Note

Use care when installing the top plate and extensions. The 9-pin

connectors are keyed. The top plate and extensions should be fitted on

straight (without bending or angling it) to make sure they engage the four

connectors simultaneously and evenly.

For front or steering axles,

anti-rotate arm must be

mounted to a part of the

unsprung suspension that

steers with the tire, such as

the brake caliper.

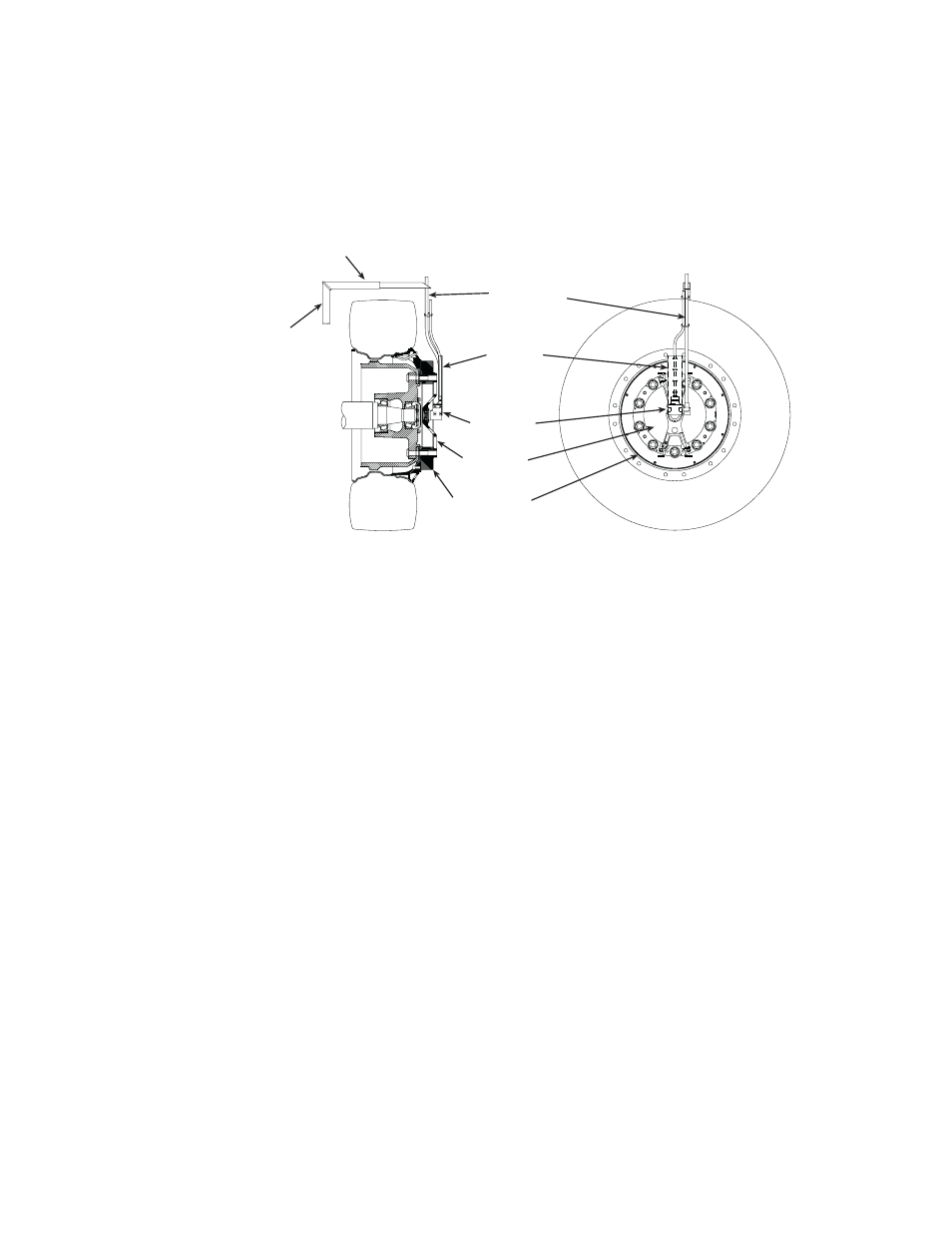

Front Wheel Slip Ring and Anti-Rotate Assembly

Anti-Rotate Bracket

(customer supplied)

Anti-Rotate

Assembly

Slip Ring

Slip-Ring

Bracket

S50-44

Transducer

Cable

Conduit

Bracket