MTS SWIFT 50 GLP Sensor User Manual

Page 37

Road and Track Vehicles

SWIFT 50 GLP Sensors Installation

Installing the Transducer

37

2. Attach the wheel/transducer to the test vehicle.

Installing the lug bolts directly against the transducer face, without the anti-

galling compound and the shim washers, can cause galling of the

transducer face.

Galling of the transducer face can result in uneven torquing (and possible

over-torquing) of the lug bolts.

To prevent galling, always use the shim washers provided. Always lubricate the

bolts and shim washers as described below.

Lubricate the lug bolt threads, under the bolt head, and both faces of the

shim washers with the Nikal based anti-galling compound.

Tighten the lug nuts in 203 N•m (150 lbf•ft) increments, in the sequence

shown in the next figure to the torque rating recommended for the wheel.

Important

Do not exceed a torque of 815 N•m (600 lbf•ft).

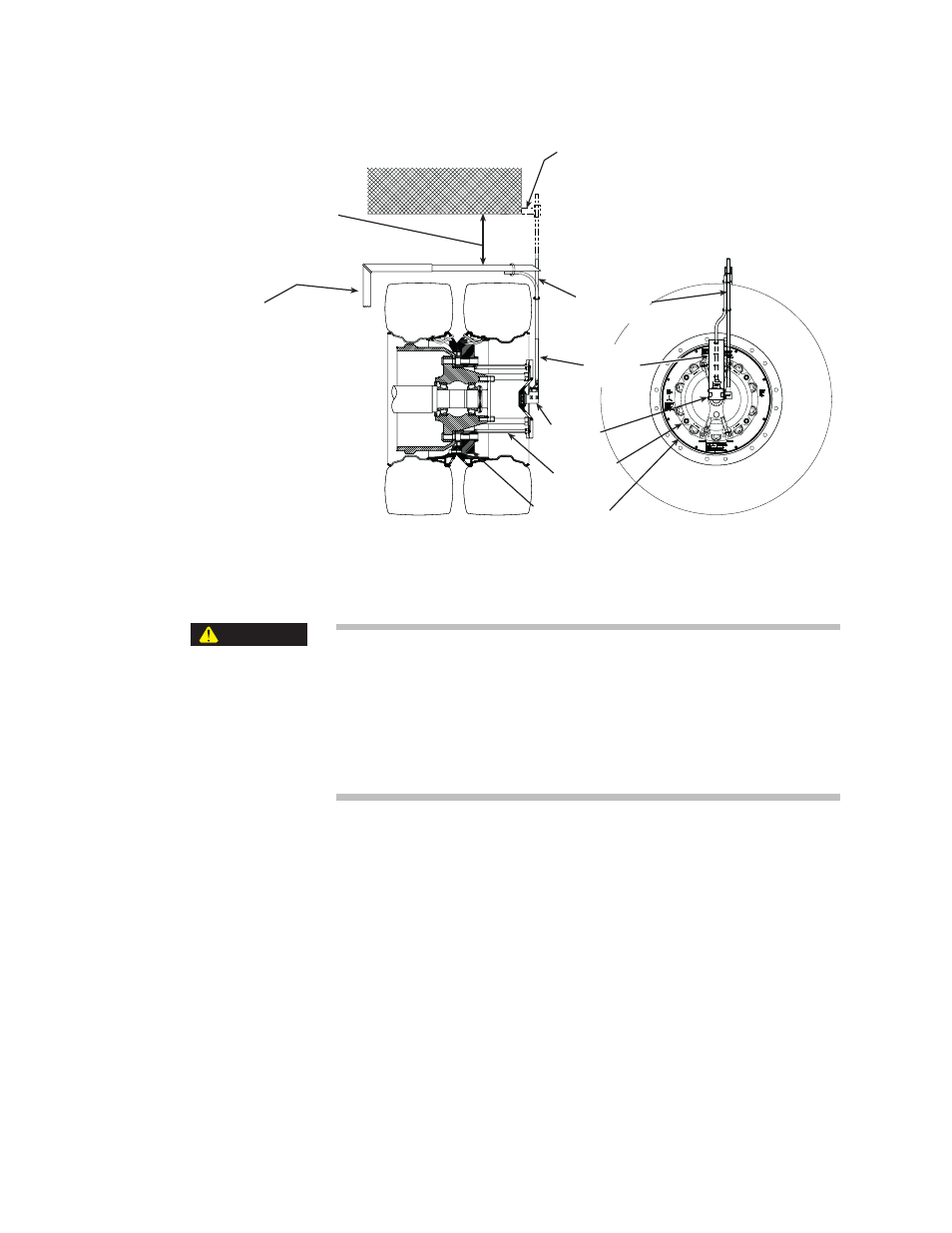

Ensure bracket will not hit

body parts during vehicle

testing or jouncing.

Slip Ring

Slip-Ring

Extension

Bracket

For dual or nonsteering axles, the

anti-rotate arm must be mounted

to the unsprung mass or

suspension, or possibly the fender

or trailer (less desireable).

If the arm is mounted to the fender

or trailer, the assembly must have

a close-fitting hole that will

accommodate the suspension

jounce travel.

The bracket can be attached to

the brake caliper if wheel hub

assembly is equipped with disc

braking system.

If the anti-rotate bracket is

fender or trailer-mounted, it

must be in a vertical orientation

so that when the vehicle

jounces the anti-rotate arm does

not rotate and cause errors in

the data or bend the rod.

The anti-rotate arm must be

long enough to accommodate

vehicle jounce.

S50-45

Dual Wheel Slip Ring and Anti-Rotate Assembly

Transducer

Anti-Rotate

Assembly

Cable

Conduit

Bracket

CAUTION