Vertical seam – Metal Sales Vertical Seam Installation User Manual

Page 39

800.406.7387 • www.metalsales.us.com

© Metal Sales Manufacturing Corporation Subject to change without notice Effective Date 5/13

39

VERTICAL SEAM

v

alley

o

ver

o

pen

f

ramIng

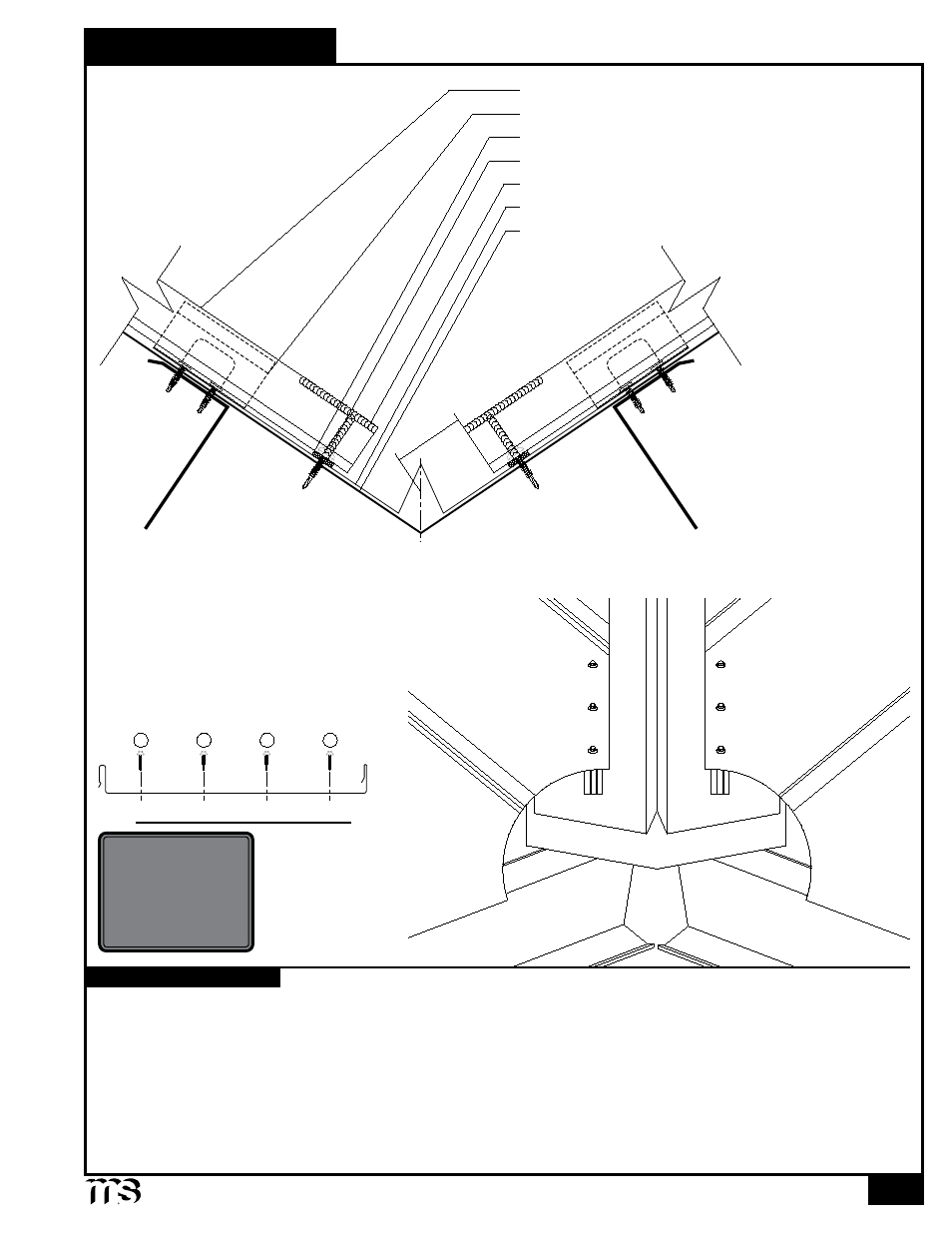

All Valley Flashings must be installed prior to panel installation. If two or more Valley Flashings are required, Valley must

be installed working from Eave to Peak.

1. Install Valley flashing back against substrate and fasten with #10-16 x 1" Pancake Head Driller (4'-0" o.c.) to hold flashing

place during installation.

2. Apply a row of Double Bead Tape Sealant across both sides of Valley flashing about 3" from the center of the valley.

3. Field cut the Vertical Seam panel to the appropriate angle and install over the Valley flashing, with (5) #12-14 x 1

1

/

4

" Self

Driller XL screws, as shown above (see pages 34-35 for panel installation).

4. If two or more flashings are required, lap the flashing over the previously installed flashing by a minimum of 2" placing a bead

of Tube Sealant between the flashings and securing with (2) pop rivets in the 1" water diverter.

Vertical Seam Clip

Valley

Vertical Seam Panel

Tube Sealant

Valley Plate

#12-14 x 1

1

/

4

" SD XL (see below)

Double Bead Tape Sealant

CAUTION

Additional screws

may be required for

high snow loading

and steep slopes.

3"

Min.

INSTALLATION NOTES

3

1

2

4

Vertical Seam Fastening Pattern

3:12 Slope

Minimum