Step 1 step 2, Vertical seam – Metal Sales Vertical Seam Installation User Manual

Page 34

800.406.7387 • www.metalsales.us.com

© Metal Sales Manufacturing Corporation Subject to change without notice Effective Date 5/13

VERTICAL SEAM

34

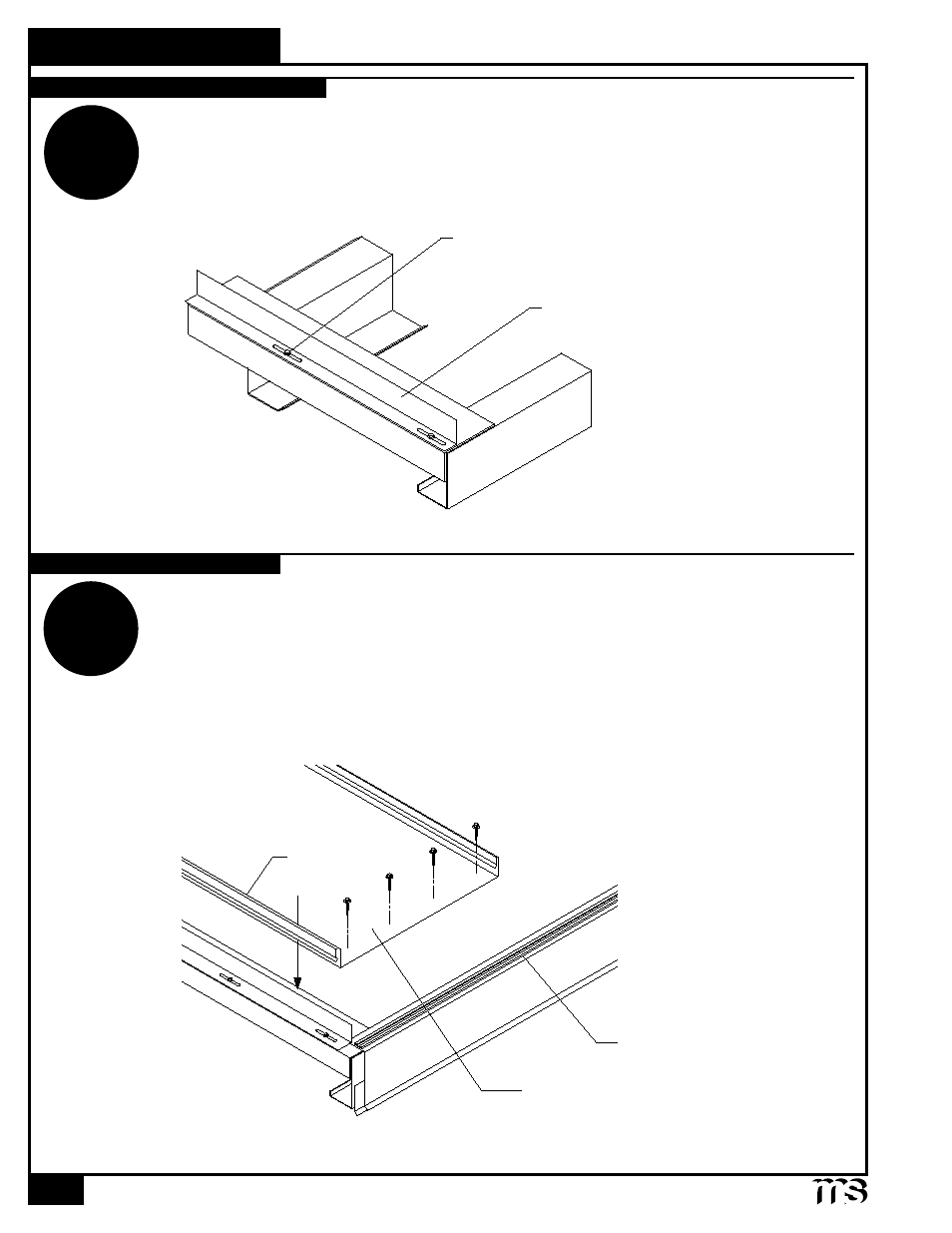

1. Install Floating Rake Angle at all rake and rake parapet conditions. Square Floating Rake Angle to rake

condition. It is critical that Floating Rake Angle be square to building as this will control alignment

of panels (see page 15 to check building square).

2. Fasten to framing with #12-14 x 1

1

/

4

" Shoulder Self Driller screws at 1'-0" o.c. Do not over tighten

screws for it is imperative that the Vertical Seam roof system be allowed to float.

3. If two or more Floating Rake Angles are required, butt ends. Do not overlap Floating Rake Angles.

I

nStallatIon

of

p

anel

o

ver

o

pen

f

ramIng

Note: Insulation, Eave, Gutter, and Valley flashings must first be installed before panel installation

can begin (see pages 36-39). Vertical Seam panels must be installed going from left to right when

looking from eave to peak.

1. Apply a row of Double Bead Tape Sealant across the top leg of the Eave (Extended Eave, Gutter) flashing.

2. Install the first panel so that the female leg is on top of the Floating Rake Angle, and has the proper

overhang. Make sure that the panel is square to the eave and rake.

3. Fasten Vertical Seam panel with (4) #12-14 x 1

1

/

4

" Self Driller XL screws through the Double Bead

Tape Sealant, flashing, and into the framing (as shown below).

INSTALLING FIRST PANEL

INSTALLING FLOATING RAKE ANGLE

STEP

1

STEP

2

Square Floating Rake Angle to Rake

Fasten Floating Rake Angle with

Shoulder Self Driller (1'-0" o.c.)

Vertical Seam Panel

Female Leg

Double Bead Tape Sealant