Vertical seam – Metal Sales Vertical Seam Installation User Manual

Page 33

800.406.7387 • www.metalsales.us.com

© Metal Sales Manufacturing Corporation Subject to change without notice Effective Date 5/13

33

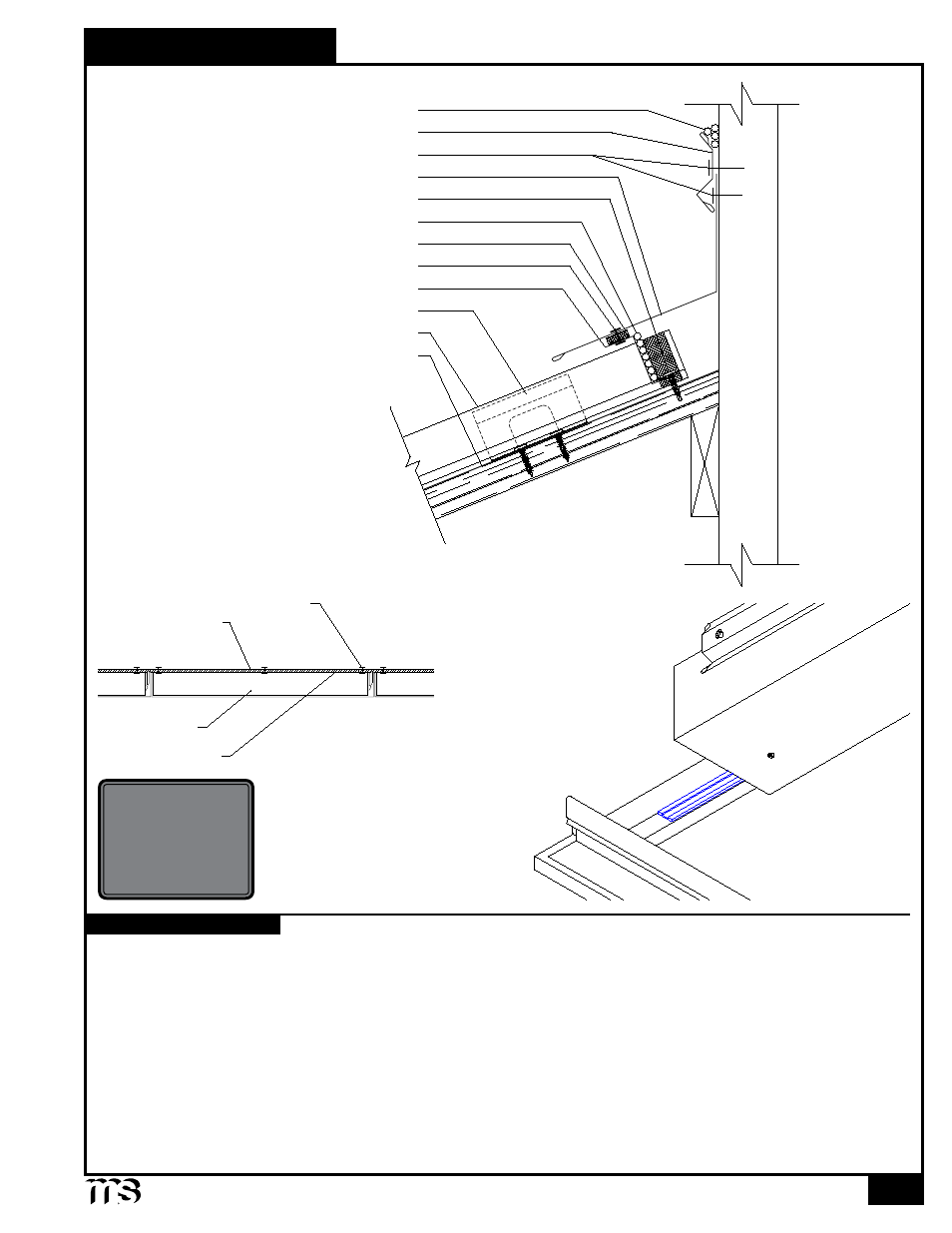

VERTICAL SEAM

h

IghSIde

p

arapet

o

ver

d

eckIng

1. Once panels have been installed, field cut the Vertical Seam Z-Closure (see page 47) to fit between the panel ribs.

2. Place a row of Double Bead Tape Sealant across panel and over each panel rib approximately 2" from panel end. Before

proceeding make sure Z-Closure placement will accommodate Pitch Break flashing.

3. Install field cut Z-Closure (as shown on page 47).

4. Fasten Z-Closure through panel with #10-12 x 1" Pancake Head Woodscrews (4 per panel).

5. Apply a continuous bead of Tube Sealant across top leg of Z-Closure filling any gaps or openings around panel ribs. Position

and install Pitch Break flashing to Z-Closure with

1

/

8

" x

3

/

16

" Pop Rivets (as shown).

6. Fasten vertical leg of Pitch Break to the parapet wall with the appropriate fastener. (1'-0" o.c.)

7. Install Counter Flashing, Reglet, or wall panel and fasten to parapet wall with appropriate fastener 1'-0" o.c. If Counter

Flashing or Reglet is used, seal to parapet wall with tube sealant. Do NOT fasten Rakewall to wall.

8. If two or more flashings are required, lap the flashing over the previously installed flashing by a minimum of 2" placing a bead

of Tube Sealant between the flashings and securing with pop rivets 2

1

/

2

" o.c.

Counter Flashing

Tube Sealant

Tube Sealant

#10-12 x 1" PHW (4 per panel)

Pitch Break

1

/

8

x

3

/

16

" Pop Rivet (see below)

Double Bead Tape Sealant

Fasteners (by others)

Vertical Seam Panel

Vertical Seam Clip

Vertical Seam Z-Closure

Moisture Barrier (by others)

CAUTION

Additional screws

may be required for

high snow loading

and steep slopes.

INSTALLATION NOTES

Pop Rivet

Flashing

Z-Closure

Tape Sealant

1:12 Slope

Minimum

over Solid

Substrate