Vertical seam – Metal Sales Vertical Seam Installation User Manual

Page 23

800.406.7387 • www.metalsales.us.com

© Metal Sales Manufacturing Corporation Subject to change without notice Effective Date 5/13

23

VERTICAL SEAM

e

xtended

e

ave

o

ver

d

eckIng

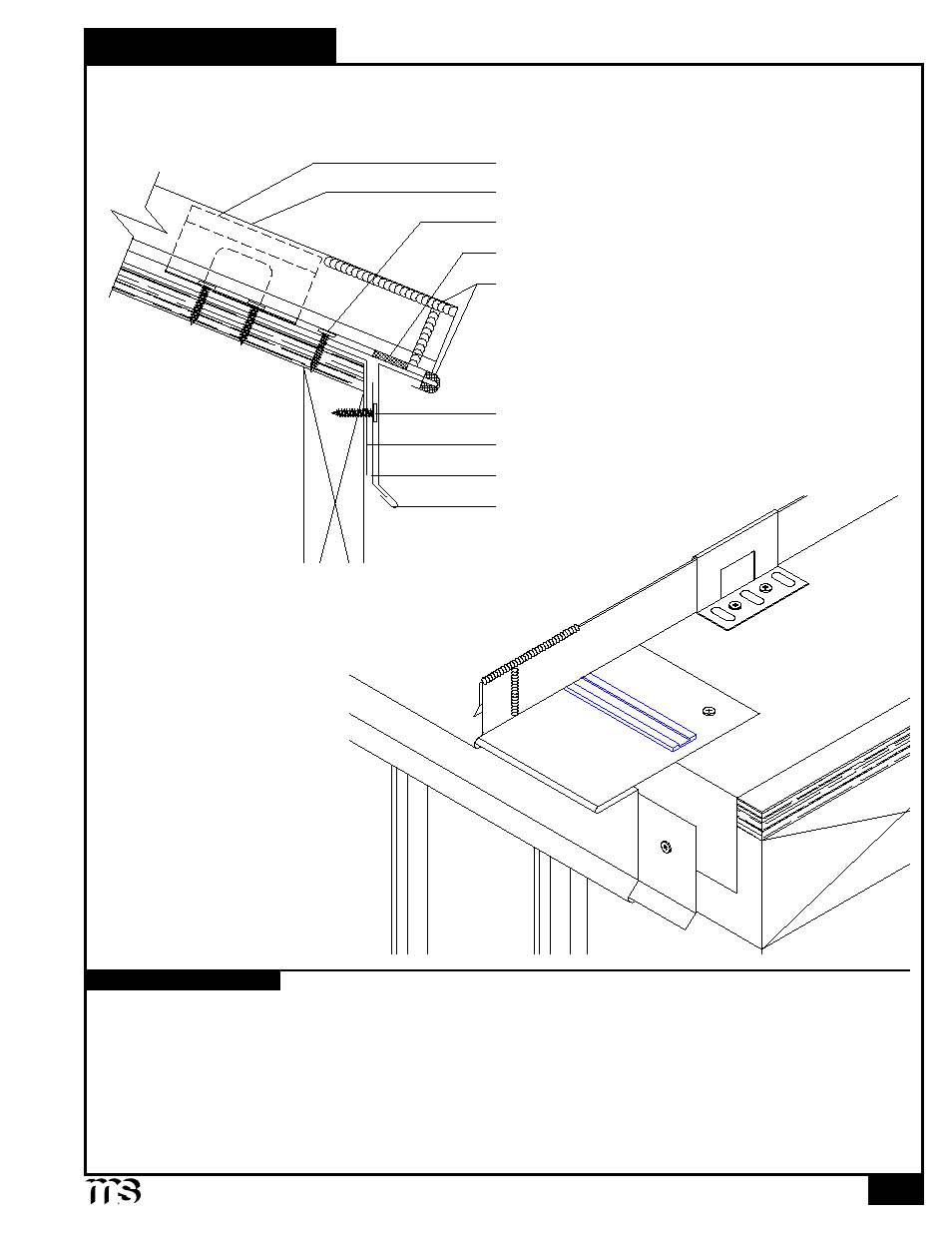

All Eave flashings must be installed prior to panel installation.

1. Position and install Cleat to wall with appropriate fastener, 1'-0" o.c. Make sure Cleat allows for proper Extended Eave

attachment.

2. Install Extended Eave flashing by sliding open hem onto Cleat and resting Extended Eave Flashing back against substrate.

Fasten to substrate with #10-12 x 1" Pancake Head Woodscrew, 1'-0" o.c.

3. Apply a row of Double Bead of Tape Sealant to extended leg of the Extended Eave flashing.

4. Install panel by engaging field hemmed end of panel (see page 18) to Extended Eave (see pages 20-21 for panel installation).

5. If two or more flashings are required, lap the flashing over the previously installed flashing by a minimum of 2" placing a bead

of Tube Sealant between the flashings and securing with pop rivets 2

1

/

2

" o.c.

#10-12 x 1" PHW (1'-0" o.c.)

Eave

Double Bead Tape Sealant

Cleat

Tube Sealant

Vertical Seam Panel

Vertical Seam Clip

Moisture Barrier (by others)

#10-12 x 1" PHW (1'-0" o.c.)

INSTALLATION NOTES

Note:

Panel rib must be

field notched and flat

part of panel must be

field bent to accept

Extended Eave

(see page 18).

1:12 Slope

Minimum

over Solid

Substrate