Installation procedures, Step 1 installing cleat & eave flashings – Metal Sales Image II Installation User Manual

Page 16

© Metal Sales Manufacturing Corporation / Subject to change without notice, effective 6/2011

16

Installation Procedures

If your building requires a Gutter instead of Eave Flashing, please

see page 22 for installation.

Moisture Barrier must be installed prior to beginning installation.

Metal Sales recommends a minimum 30# felt moisture barrier.

To avoid panel distortion, use a properly aligned and uniform

substructure.

All Cleat and Eave flashings must be installed prior to panel

installation.

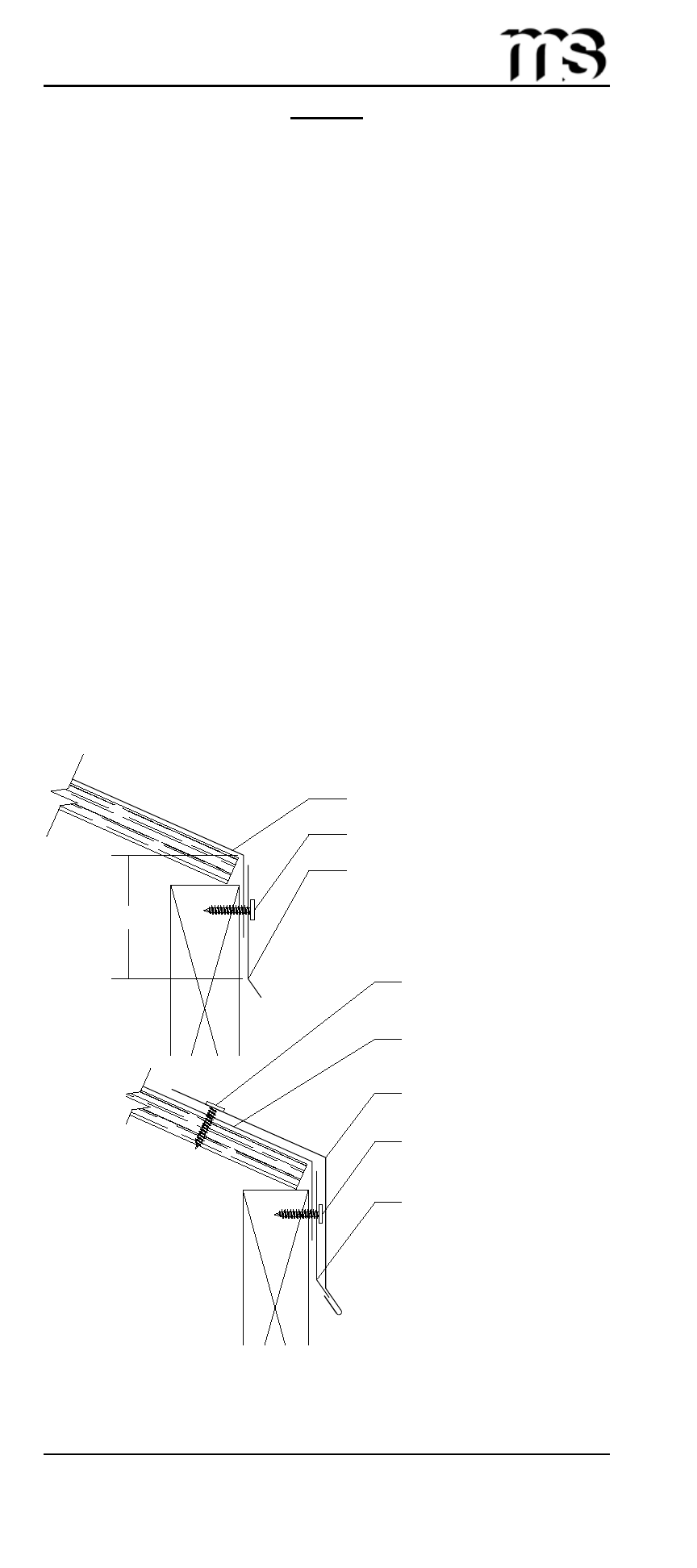

1. Position Cleat on wall at the appropriate distance from roof-

line. Make sure Cleat allows for proper Eave attachment.

2. Attach Cleat to wall with #8-18 x

3

/

4

" Truss Head Woodscrews,

1' o.c.

3. Install Eave flashing by inserting the open hem of the Eave

flashing onto the bottom leg of the Cleat and rest the Eave

flashing against the substrate.

4. Fasten Eave flashing to substrate with #8-18 x

3

/

4

" Truss Head

Woodscrews, 4' o.c. to hold the Eave flashing in place during

installation.

Note: If two or more flashings are required, lap the flashing over the

previously installed flashing by a minimum of 2" placing 2 beads of

Tube Sealant between the flashings and securing with Pop Rivets,

2" o.c.

Step 1

Installing Cleat & Eave Flashings

Moisture Barrier

Truss Head Woodscrew,

1' o.c. (2)

Cleat (1)

3"*

Moisture Barrier

Eave (3)

Cleat (1)

Truss Head Woodscrew,

1' o.c. (2)

Truss Head Woodscrew,

4' o.c. (4)

* 3" Dimension is based on the standard Eave Flashing (See

page 9) Dimension may vary with different flashings.

(X) Numbers indicate sequence of installation.