Gauge wheel installation, Hydraulic lift installation - rigid and 15’ fold – Landoll 875 Series Tilloll User Manual

Page 25

ASSEMBLY INSTRUCTIONS

3-9

Gauge Wheel Installation

1.

All gauge wheel arms, rockshafts, and hubs come

already assembled from the factory.

2.

Mount the tires on the wheels and install on the hubs.

3.

Recommended tires: 11L X 15 10 ply

Hydraulic Lift Installation - Rigid

and 15’ Fold

IMPORTANT

Read all safety precautions at the front of the section

before attempting any of the following procedures.

1.

Install stroke control and stroke control cover on

master cylinder(s), and parallel system cylinder on

15’ fold model. Replace cylinder yoke(s). Adjust

cylinder extended length to measure 28-1/4" from

hole center to hole center. Tighten lock bolt or set

screw to lock yoke in place.

NOTE

Always adjust the slave cylinder extended length to

measure the same as the master cylinder to allow the

unit to operate level in the field.

2.

Install the master cylinders (all models) and slave

cylinder (rigid models) on the main frame ports up,

using clevis pin and cotter pins. Connect rod to

gauge wheel arm or rockshaft using extended pin

and 1/4 hair pins.

3.

Install the non-series cylinder on the 15’ fold model

on the main frame ports up, using clevis pin and

cotter pins. Connect rod to gauge wheel arm or

rockshaft using extended pin and 1/4 hair pins.

4.

Install the slave cylinder on the 15’ fold model on the

wing frame ports up, using clevis pin and cotter pins.

Connect rod to gauge wheel arm or rockshaft using

extended pin and 1/4 hair pins.

5.

Install 90

o

adapters into base and rod end of each lift

cylinder.

6.

Install hoses (See Figures 3-6 and 3-7 and

Table 3-1).

IMPORTANT

All cylinder ports are plugged. Do not forget to

remove all plugs and replace with hoses or fittings

before applying hydraulic pressure to cylinders.

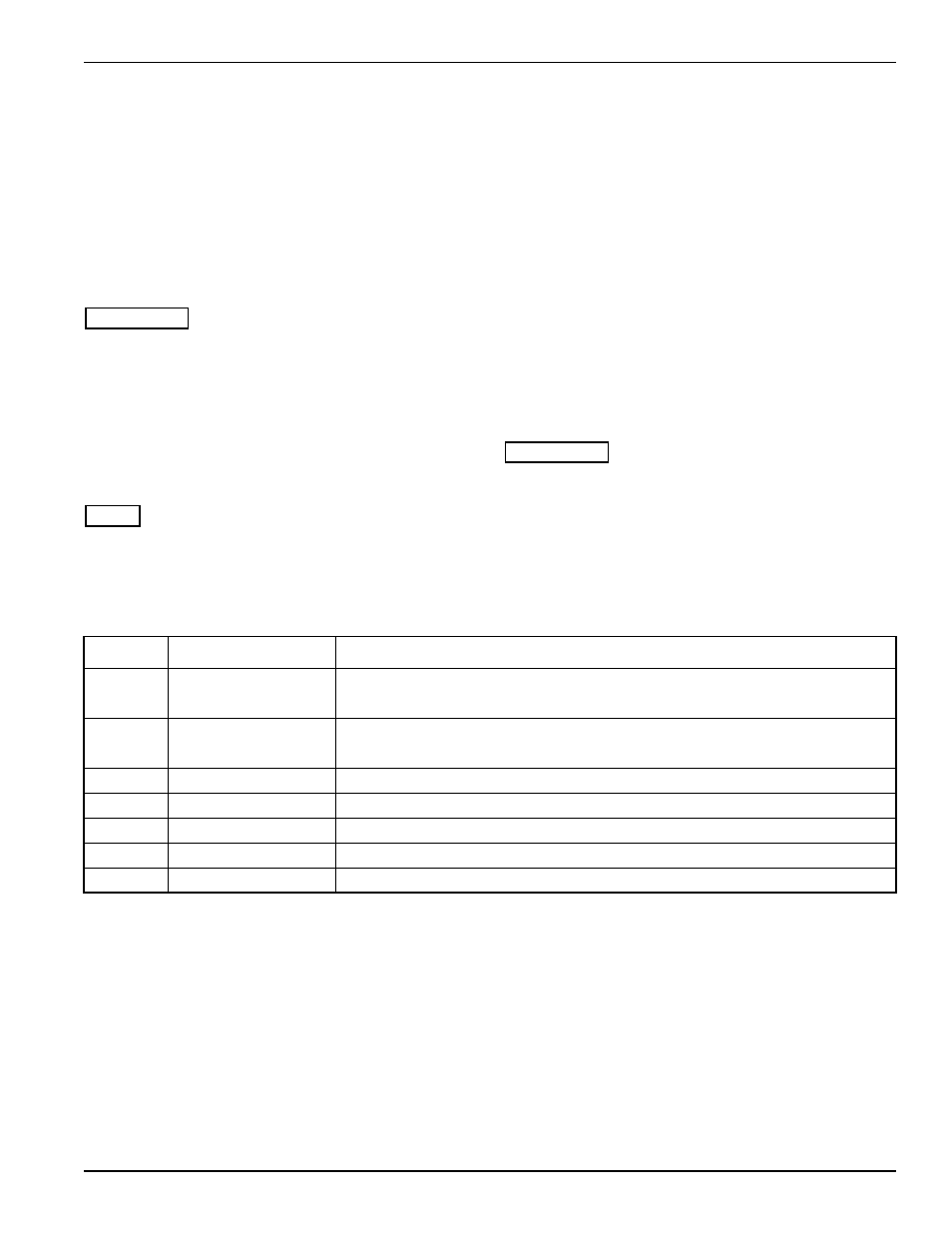

Table 3-1: Hydraulic Hose Installation - Rigid and 15’ Fold

ITEM

PART NO.

HOSE LENGTH (MODEL USED)

A

1-397-010301114

1/2 X 114 (875-10)

1-397-010301194

1/2 X 194 (875-13 & 875-15)

B

1-397-010301238

1/2 X 238 (875-10)

1-397-010301284

1/2 X 284 (875-13 & 875-15)

C

162780

1/2 X 251 (875-15F)

D

71508984

3/8 X 42 (875-15F)

E

137602

3/8 X 27 (875-15F)

F

1422176

3/8 X 116 (875-15F)

G

117260

3/8 X 156 (875-15F)