Bryant Deluxe 4 WAy Gas Furnase 355MAV User Manual

Page 55

m. Move setup switch SW-2 to OFF position and jumper R and W2 thermostat connections. (See Fig. 31.) This keeps furnace locked in

high-heat operation. Repeat items h through k for high-heat operation.

EXAMPLE: (High-heat operation at 0-2000 ft altitude)

Furnace input from rating plate is 100,000 Btuh.

Btu heating input = Btu/cu ft X cu ft/hr

Heating value of gas = 975 Btu/cu ft

Time for 1 revolution of 2-cu ft dial = 70 sec

Gas rate = 103 cu ft/hr (from Table 15)

Btu heating input = 103 X 975 = 100,425 Btuh. In this example, the orifice size and manifold pressure adjustment is within ±2 percent of

the furnace input rate.

NOTE: Measured gas inputs (high heat and low heat) must be within ±2 percent of that stated on furnace rating plate when installed at sea level

or derated per that stated above when installed at higher altitudes.

n. Remove jumper across R, W/W1, and W2 thermostat connections to terminate call for heat.

B. Set Temperature Rise

CAUTION: Temperature rise must be within limits specified on unit rating plate. Recommended operation is at

midpoint of rise or above. Failure to follow this caution may result in overheating the heat exchangers or condensing flue

gases in heat exchanger areas not designed for condensate.

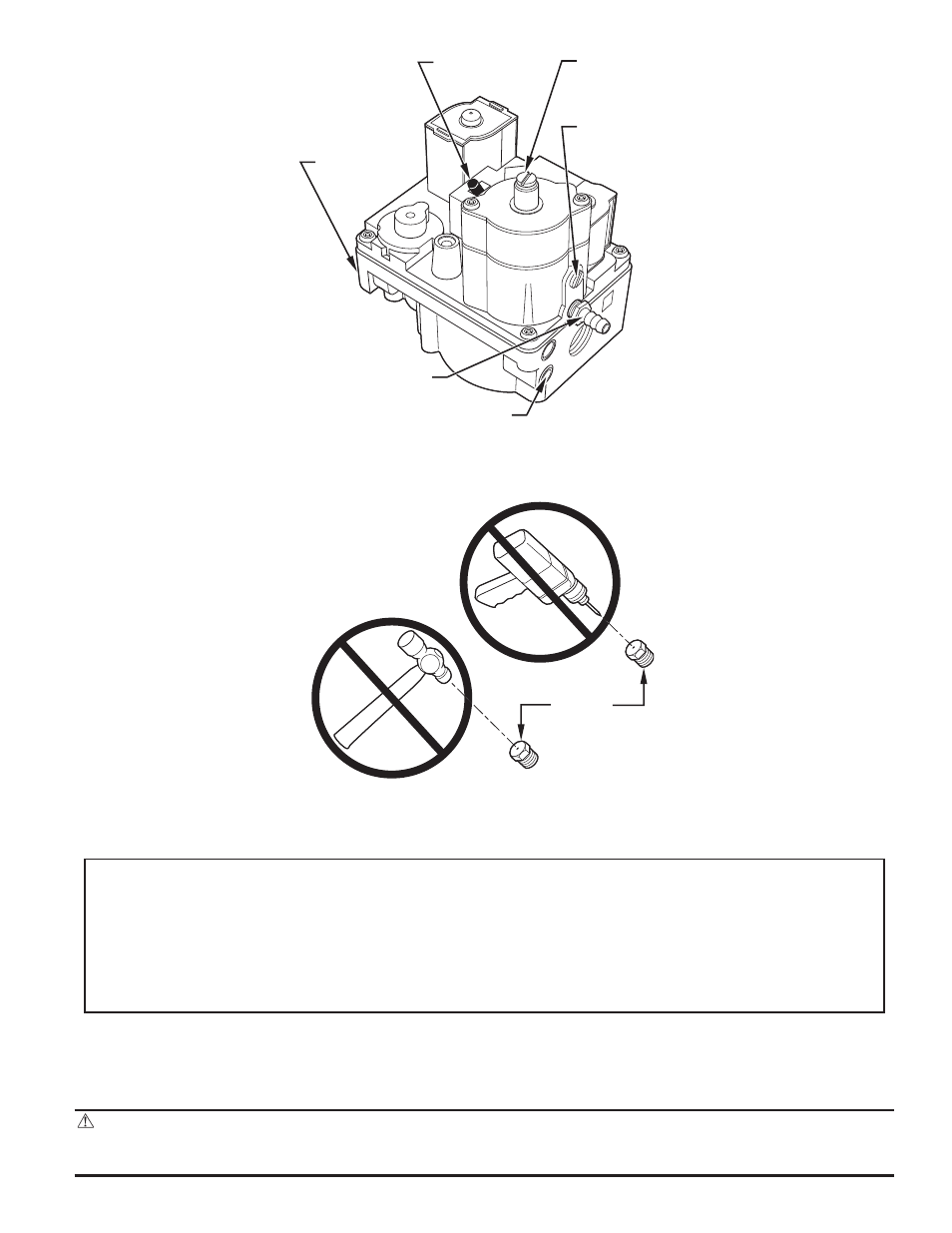

Fig. 56—Redundant Automatic Gas Valve

A97386

ON/OFF

SWITCH

INLET

PRESSURE

TAP

ON

O

F

F

BURNER

ENCLOSURE

REFERENCE

PRESSURE TAP

MANIFOLD

PRESSURE

TAP

LOW-FIRE

ADJUSTMENT

ALLEN SCREW

(UNDER CAP)

HIGH-FIRE

ADJUSTMENT

ALLEN SCREW

(UNDER CAP)

Fig. 57—Burner Orifice

A93059

BURNER

ORIFICE

—55—