Installation – Bryant Deluxe 4 WAy Gas Furnase 355MAV User Manual

Page 5

Before installing the furnace in Canada, refer to the current edition of the NSCNGPIC. Contact Standard Sales CSA International, 178 Rexdale

Boulevard, Etobicoke, (Toronto) Ontario, Canada M9W 1R3.

Installation must comply with regulations of serving gas supplier and local building, heating, plumbing or other codes in effect in the area in which

installation is made. In absence of local codes, installation must comply with the NFGC in the United States and the NSCNGPIC in Canada.

These instructions cover minimum requirements for a safe installation and conform to existing national standards and safety codes. In some

instances, these instructions exceed certain local codes and ordinances, especially those that may not have kept pace with changing residential

construction practices. We require these instructions as a minimum for a safe installation.

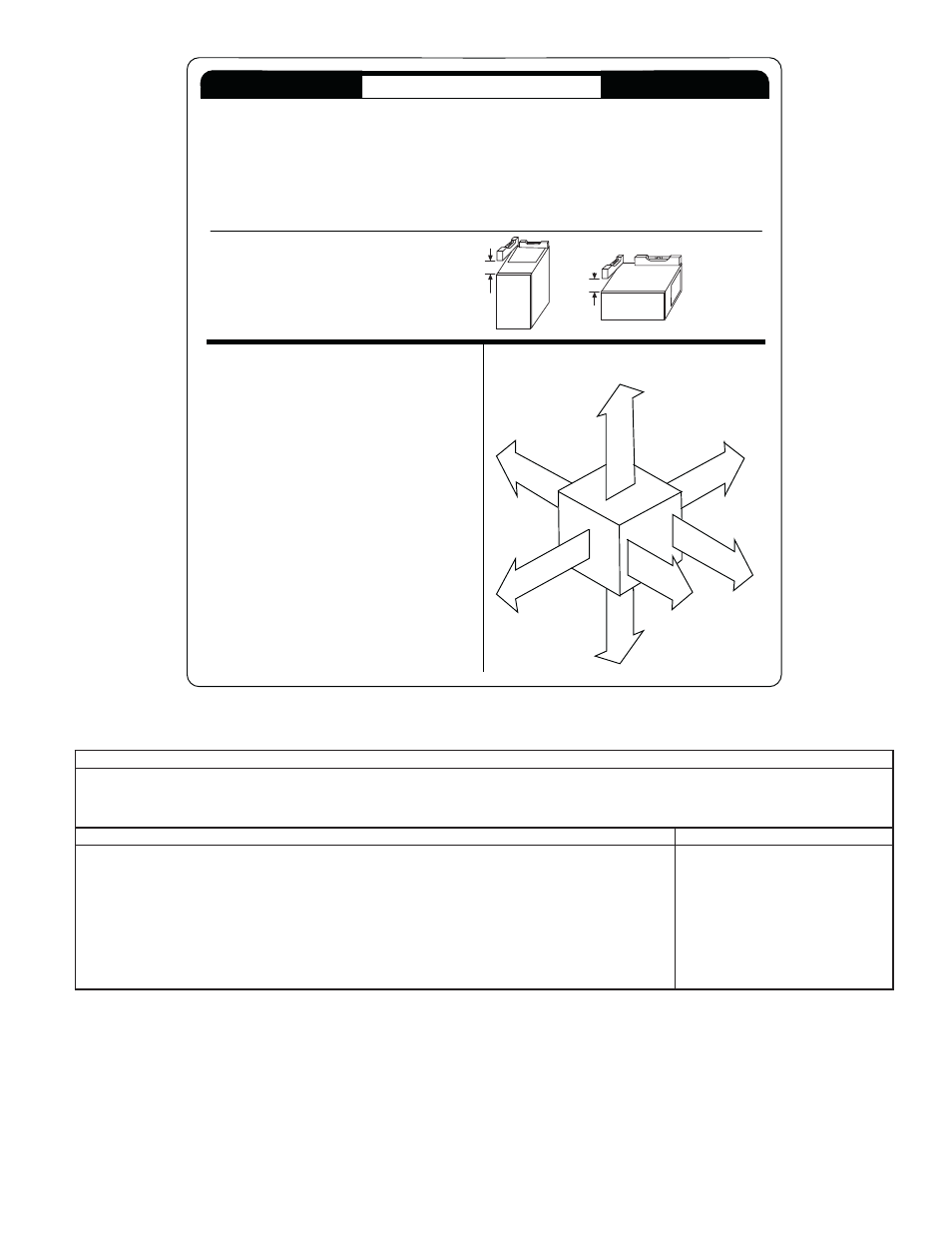

Fig. 3—Clearances to Combustibles

A99103

FRONT

FRONT

This forced air furnace is equipped for use with natural gas at altitudes 0 - 10,000 ft (0 - 3,050m).

An accessory kit, supplied by the manufacturer, shall be used to convert to propane gas use or may be required for some natural

gas applications.

This furnace is for indoor installation in a building constructed on site. This furnace may be installed in a manufactured (mobile)

home when stated on rating plate and using factory authorized kit.

This furnace may be installed on combustible flooring in alcove or closet at minimum clearance from combustible material.

This appliance requires a special venting system. Refer to the installation instructions for parts list and method of installation. This

furnace is for use with schedule-40 PVC, PVC-DWV, or ABS-DWV pipe, and must not be vented in common with other gas-fired

appliances. Construction through which vent/air intake pipes may be installed is maximum 24 inches (600 mm), minimum 3/4 inches

(19 mm) thickness (including roofing materials).

Clearance in inches.

Vent clearance to

combustibles 0".

This furnace is approved for UPFLOW, DOWNFLOW and

HORIZONTAL installations.

*

BO

TT

O

M

0"

Ø

3"

0"

§

0"

TO

P/

PL

EN

U

M

1"

0"

§

30

MIN

ALL POSITIONS:

S I

D E

F R

O N

T

B

C K

A

S E

R VI

E

C

FR

ON

T

S I

D E

U

F

R N

A C

E

Clearance arrows

do not change with

furnace orientation.

†

HORIZONTAL

UPFLOW OR

DOWNFLOW

1/2" MAX

1/2" MAX

TO

LEVEL (0")

LEVEL (0")

TO

325400-201 REV. A

MINIMUM INCHES CLEARANCE TO

COMBUSTIBLE CONSTRUCTION

†

HORIZONTAL POSITIONS:

DOWNFLOW POSITIONS:

§

Ø

*

Mimimum front clearance for service 30 inches

(762mm).

For installation on combustible floors only when

installed on special base No. KGASB0201ALL, Coil

Assembly, Part No. CD5 or CK5, or Coil Casing, Part

No. KCAKC.

Clearance shown is for air inlet and air outlet end.

Line contact is permissible only between lines

formed by intersections of top and two sides of furnace

jacket, and building joists, studs, or framing.

120 size Furnace require 1 inch bottom clearance to

combustible materials.

Furnace must be installed level, or

pitched forward within 1/2 inch of level

for proper drainage. Failure will result in

equipment or property damage. See

Installation Manual for IMPORTANT unit

support details on horizontal

applications.

INSTALLATION

(LIT. TOP)

INSTALLER PACKET INCLUDES:

Installation, Startup, and Operating Instructions

Service and Maintenance Instructions

User’s Information Manual

Warranty Certificate

Loose Parts Bag includes:

Quantity

Pressure tube extension

Collector Box or condensate trap extension tube

Inducer housing drain tube

1/2-in CPVC street elbow

Drain tube coupling

Drain tube coupling grommet

Vent and combustion-air pipe support

Combustion-air pipe perforated disk assembly

Condensate trap hole filler plug

Vent and combustion-air intake hole filler plug

1

1

1

2

1

1

2

1

3

2

—5—