Bryant Deluxe 4 WAy Gas Furnase 355MAV User Manual

Page 50

2. Locate setup switches on control center. (See Fig. 31.)

3. See Table 11 for setup switch description. (See Fig. 30.)

4. Replace main furnace door and blower access panel.

NOTE: If a bypass humidifier is used, setup switch SW-3 (BPH) should be in ON position. This prevents nuisance limit trips caused by the

increased temperature in return air resulting from bypass.

NOTE: If modulating dampers are used, setup switch SW-5 (MZ) should be in ON position. This allows furnace control center to compensate

for modulating dampers. The control re-calibrates for new system static conditions once every minute while operating in low-heat or continuous

fan modes.

PROCEDURE 3—PRIME CONDENSATE TRAP WITH WATER

CAUTION: Condensate trap must be PRIMED or proper draining may not occur. The condensate trap has 2 internal

chambers which can ONLY be primed by pouring water into the inducer drain side of condensate trap.

1. Remove upper inducer housing drain connection cap. (See Fig. 54.)

2. Connect field-supplied 1/2-in. ID tube to upper inducer housing drain connection.

3. Insert field-supplied funnel into tube.

4. Pour 1 quart of water into funnel/tube. Water should run through inducer housing, overfill condensate trap, and flow into open field drain.

(See Fig. 55.)

5. Remove funnel and tube from inducer housing and replace drain connection cap and clamp.

PROCEDURE 4—PURGE GAS LINES

If not previously done, purge the lines after all connections have been made and check for leaks.

WARNING: Never purge a gas line into a combustion chamber. Never use matches, candles, flame, or other sources

of ignition for the purpose of checking leakage. Use a soap-and-water solution to check for leakage. Failure to follow this

warning could result in fire, explosion, personal injury, or death.

PROCEDURE 5—ADJUSTMENTS

A. Set Gas Input Rate

Furnace gas input rate on rating plate is for installations at altitudes up to 2000 ft.

In the U.S.A., the input rating for altitudes above 2000 ft must be reduced by 2 percent for each 1000 ft above sea level.

In Canada, the input rating must be derated by 5 percent for altitudes of 2000 ft to 4500 ft above sea level.

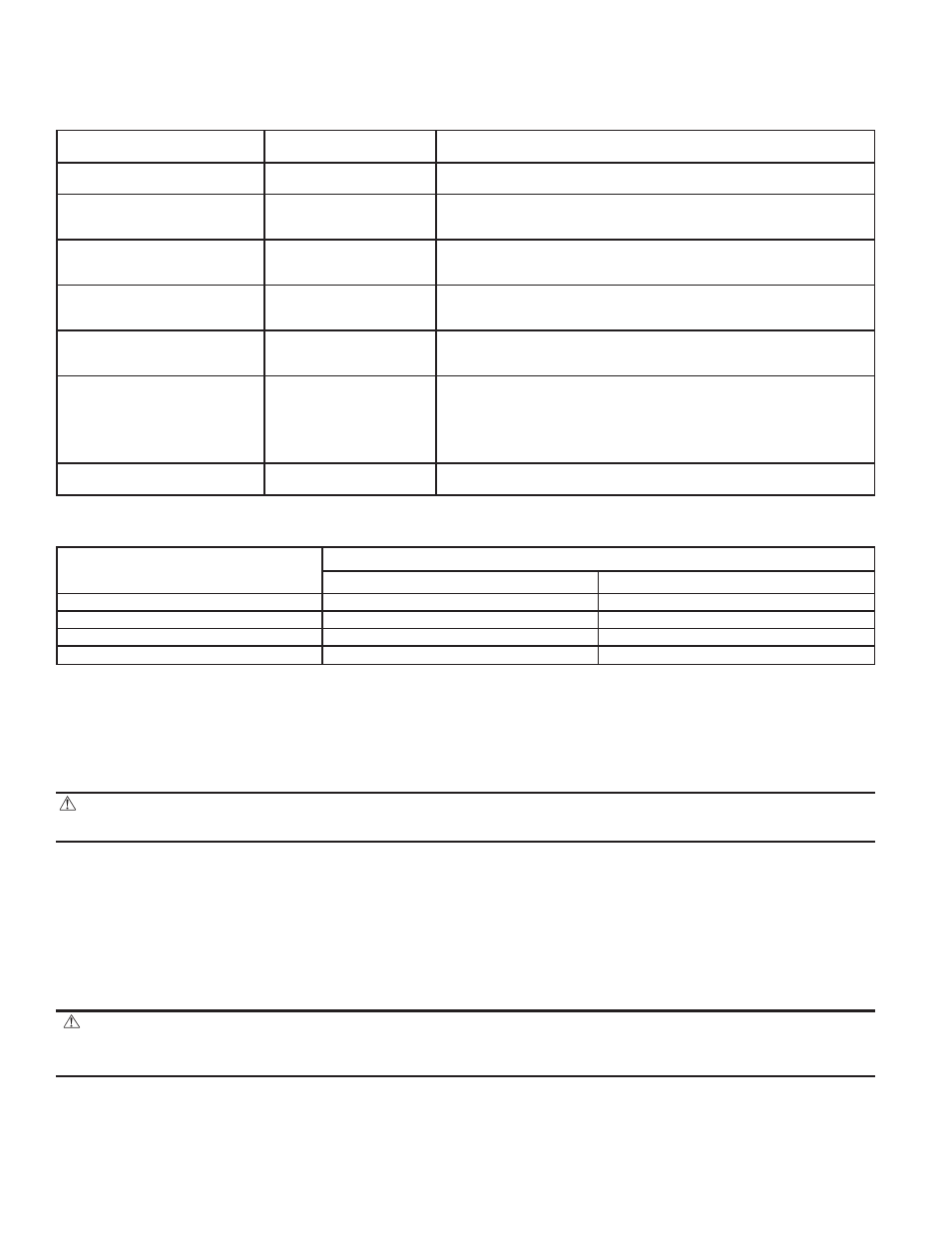

Table 11—Setup Switch Description

SETUP

SWITCH NO.

NORMAL

POSITION

DESCRIPTION

OF USE

SW-1

(FLT)

OFF

Turn switch to ON for fault history display. No thermostat signal

can be present for fault history display.

SW-2

(LOW)

OFF

Turn switch to ON to lock furnace in low-heat mode only or

when using a 2-stage thermostat with a R-W/W1 and R-W2 sig-

nals.

SW-3

(BPH)

OFF

Turn switch to ON when a bypass humidifier is used. This com-

pensates for higher return-air temperature and provides 15 per-

cent more airflow in low-heat mode only.

SW-4

(EMER HEAT)

OFF

Turn switch to ON to bypass microprocessor control. Furnace

will operate at high heat only with main blower and inducer mo-

tor operating at maximum RPM. NO safeties are bypassed.

SW-5

(MZ)

OFF

Turn switch to ON when modulating dampers are used. In this

mode, main blower speed is recalculated once every minute

while furnace is in low-heat or continuous fan mode.

SW-6

(COMP TEST)

OFF

Turn switch to ON to initiate component test. Furnace will oper-

ate inducer motor for 20 sec at low speed, operate inducer motor

for 20 sec at high speed, energize HSI for 15 sec, operate blower

for 20 sec at low speed, and operate blower for 20 sec at high

speed. SW-1 must be in OFF position. No thermostat signal can

be present for component test to be initiated.

SW-7 and SW-8

(Blower Off Delay)

See Table 12

Adjust switches to provide desired heating mode blower off de-

lay time. 90, 135, 180, or 225 sec.

Table 12—Blower Off Delay Setup Switch Position

DESIRED HEATING

MODE BLOWER

OFF DELAY (SEC)

SETUP SWITCH (SW-7 AND SW-8) POSITION

SW-7

SW-8

90

OFF

OFF

135

ON

OFF

180

OFF

ON

225

ON

ON

—50—