8 repair, 9 accessories, 10 troubleshooting – Festo DGP(L)-…-B User Manual

Page 8: 11 technical data

8

Repair

• Recommendation: Return the product to our repair service for overhaul.

This ensures that special attention will be paid to the necessary fine adjust-

ments and inspections.

• Information about spare parts and aids can be found at:

www.festo.com/spareparts

9

Accessories

Please select the appropriate accessories from our catalogue

www.festo.com/catalogue/DGP

10

Troubleshooting

Malfunction

Possible cause

Remedy

Uneven movement of the slide

One-way flow control valve not

fitted correctly

If possible reduce the exhaust

(not the supply air)

Guide rail not greased

Lubricate guide rail

7 Maintenance and care

Faults in position scanning

Ferritic parts in the vicinity of

the proximity sensor

Use parts consisting of

non-magnetic materials or

observe minimum clearances

5.3 Fitting electric

components

Heavy leakage

Cylinder is distorted

Fasten the cylinder to a flat

base.

Seal worn

Replace worn parts:

– yourself with wearing parts

kit

– by returning to Festo for

repairs

Sealing band pressed/sucked

in

Avoid creating a vacuum in the

piston chamber (e.g. only move

the unpressurised slide slowly)

Cylinder does not reach the

desired speed

Air volume not sufficient

– Select tubing with larger

diameter

– Switch volume upstream

High friction or counteracting

force

Observe maximum limits

Fig. 18

11

Technical data

DGP(L)

18

25

32

40

50

63

80

Pneumatic connection

M5

G

Á

G

Á

G

¼

G

¼

G

Å

G½

Mode of operation

Double-acting

Mounting position

Any

(Recommendation for stroke lengths

> 2 000 mm and

horizontal installation: Install the DGP(L) with the

sealing band facing down)

Operating medium

Use as cylinder:

Compressed air as per ISO 8573-1:2010 [7:–:–]

Use as

positioning axis:

Compressed air as per ISO 8573-1:2010 [6:4:4]

Operating pressure

[bar]

2 … 8

1.5 … 8

Ambient temperature

[°C]

–10 … +60

Theoretical force at 6 bar

[N]

153

295

483

754

1 178

1 870

3 016

Speeds

DGPL

(min … max)

GF

[m/s]

0,05 … 1

KF

[m/s]

0.2 … 3

GA

[m/s]

–

0.2 … 3

–

–

Cushioning length

PPV

[mm]

16

18

20

30

30

30

85

Cushioning

PPV

Pneumatic cushioning, adjustable at both ends

Max. energy

Diagrams

Catalogue specifications

Materials

End cap/profile

Anodised aluminium

Cover strip

Steel

Driver

Anodised aluminium

Slide

Anodised aluminium

Guide rail

GF

Anodised aluminium

KF

Steel

Corrosion-resistant steel

Seals

Nitrile rubber, polyurethane

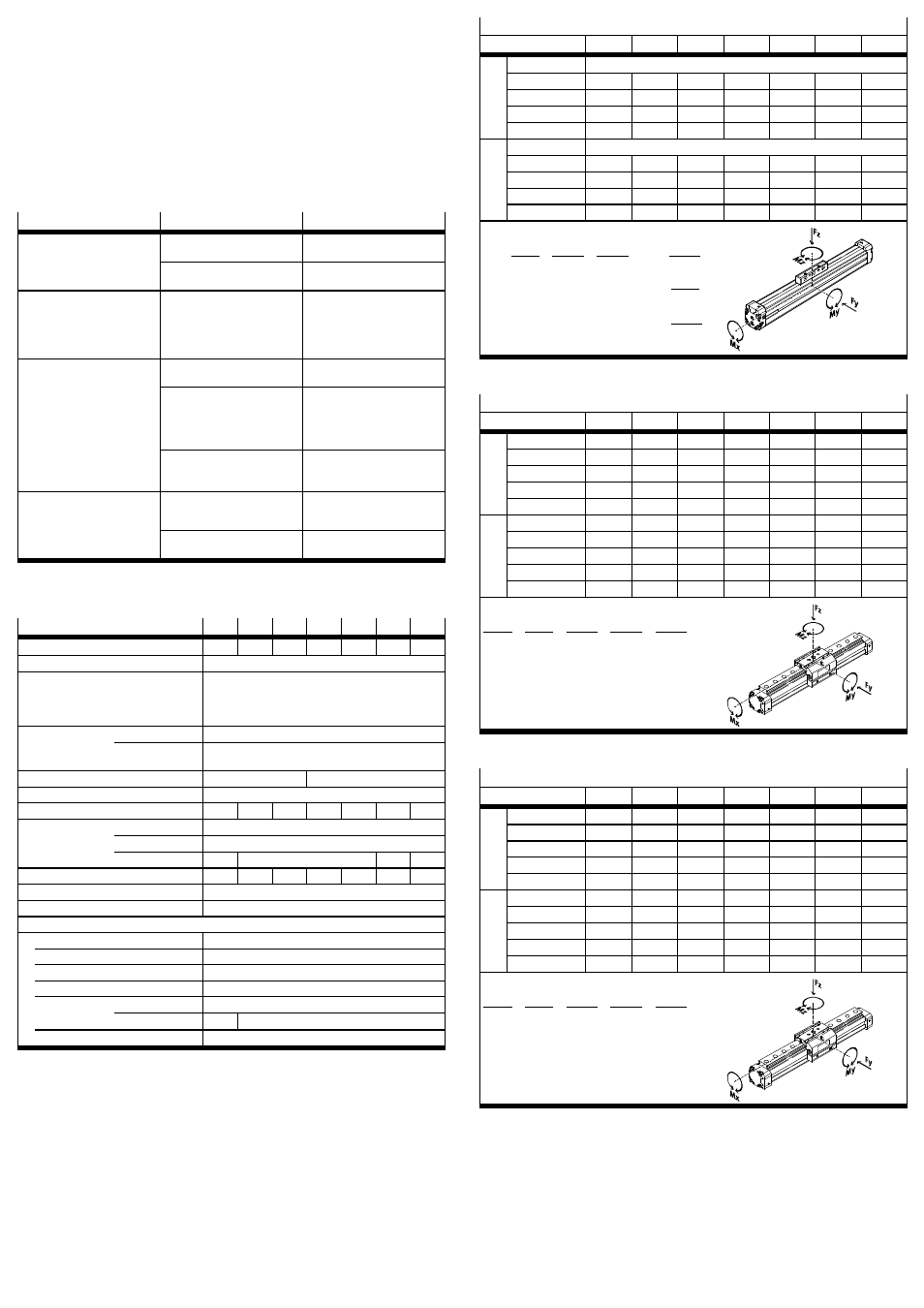

Fig. 19

Permitted force and torque loading

DGP

18

25

32

40

50

63

80

GK

Fymax

[N]

–

Fzmax

120

330

480

800

1 200

1 600

5 000

Mxmax

[Nm]

0.5

1

2

4

7

8

32

Mymax

11

20

40

60

120

120

750

Mzmax

1

3

5

8

15

24

140

GV

Fymax

[N]

–

Fzmax

120

330

480

800

1 200

1 600

–

Mxmax

[Nm]

1

2

4

8

14

16

–

Mymax

22

40

80

120

240

240

–

Mzmax

2

6

10

16

30

48

–

Formula for combined loadings:

0, 4 × Fz

Fzmax.

+ Mx

Mxmax.

+

My

Mymax.

+ 0, 2 × Mz

Mzmax.

≤ 1

Fz

Fzmax.

≤ 1

Mz

Mzmax.

≤ 1

Fig. 20

Permitted force and torque loading

DGPL-GF

18

25

32

40

50

63

80

GK

Fymax

[N]

340

430

430

1 010

1 010

2 000

2 000

Fzmax

340

430

430

1 010

1 010

2 000

2 000

Mxmax

[Nm]

2.2

5.4

8.5

23

32

74

100

Mymax

10

14

18

34

52

140

230

Mzmax

10

14

18

34

52

140

230

GV

Fymax

[N]

330

400

395

930

870

1 780

–

Fzmax

330

400

395

930

870

1 780

–

Mxmax

[Nm]

2

5

8

21

28

66

–

Mymax

18

25

30

58

83

235

–

Mzmax

18

25

30

58

83

235

–

Formula for combined loadings:

Fy

Fymax.

+ Fz

Fzmax.

+ Mx

Mxmax.

+

My

Mymax.

+ Mz

Mzmax.

≤ 1

Fig. 21

Permitted force and torque loading

DGPL-KF

18

25

32

40

50

63

80

GK

Fymax

[N]

930

3 080

3 080

7 300

7 300

14 050

14 050

Fzmax

930

3 080

3 080

7 300

7 300

14 050

14 050

Mxmax

[Nm]

7

45

63

170

240

580

745

Mymax

23

85

127

330

460

910

1 545

Mzmax

23

85

127

330

460

910

1 545

GV

Fymax

[N]

930

3 080

3 080

7 300

7 300

14 050

–

Fzmax

930

3 080

3 080

7 300

7 300

14 050

–

Mxmax

[Nm]

7

45

63

170

240

580

–

Mymax

45

170

250

660

920

1 820

–

Mzmax

45

170

250

660

920

1 820

–

Formula for combined loadings:

Fy

Fymax.

+ Fz

Fzmax.

+ Mx

Mxmax.

+

My

Mymax.

+ Mz

Mzmax.

≤ 1

Fig. 22