Enerpac CDT-Series User Manual

Page 6

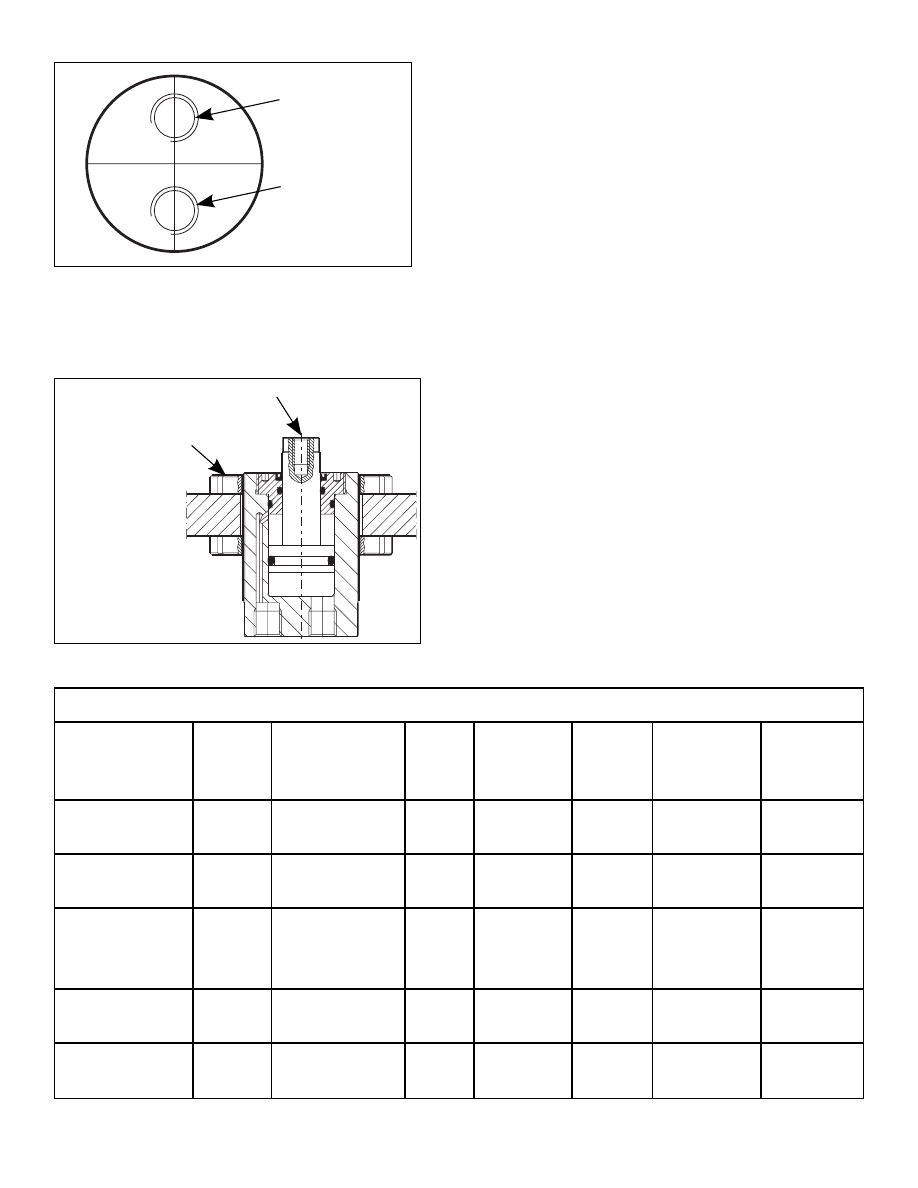

A

B

Illustration 2 - CDT Oil Port

Use flange nuts to secure all cylinders in

position and to provide a stable mounting.

(See illustration 3)

Illustration 3 - CST-CDT Cylinder

CSM cylinders are mounted in the following

steps 1-4 below:

1.

Clean the mounting hole in the manifold

or fixture. Make sure chips and dirt are

removed from the mounting threads

and oil channels.

2. Lubricate the seal prior to assembly.

(See illustration 1a and 1b)

3. Mount the cylinder with the seal

between the hexagonal flange and the

manifold or fixture.

4.

Fasten the cylinder according to the

torque values identified in Tables B4

and C5.

Enerpac recommends the use of contact

bolts on plungers using an internal thread.

6.0 MAINTENANCE AND SERVICE

Regularly inspect all components to detect

any problem requiring maintenance and

service. Replace worn or damaged parts.

I. Retract

II. Extend

I.

II.

Table B4, Manifold dimensions in mm (see illustration 4)

Model

∅ B C

D

min

E

Torque

Seal

No.

A

max

Full

min Nm Model

min

Thread [ft-lbs] No.

CSM272

22,5

26

CSM2132

19

M12 x 1,5

1,0

33,5 36

30

[21] LS-12

CSM572

29

CSM5132

29 M20

x

1,5

1,0 14,0

38

90 [66]

LS-20

CSM1072

29

CSM10132

38

M28 x 1,5

1,5

16,0

35

150 [109]

LS-28

CSM10192

50

CSM18132

3

CSM18252

47 M36

x

1,5

1,5 20,0

58

250 [188]

LS-36

CSM27152

39

CSM27252

54

M42 x 1,5

2,5

20,0

59

400 [295] LS-42

I.

II.

I. Flange Nut

II. Contact Bolt Hole

6