Enerpac NS-Series User Manual

Page 7

7

CAUTION: Be careful when handling blades. Fractured

edges can be sharp. Wear appropriate hand protection

when removing and installing blades.

3. Determine if the old blade has any reusable edges. If a new

blade is to be installed, refer to Section 3.1 for replacement

blade part numbers. Be sure to use the proper blade for the

cutting head used on your nut splitter model.

4. From the underside of the head, slide the new or rotated blade

into the dovetail shaped groove in the blade holder, until the

ball detent snaps into position. The blade is fully installed

when the bottom of the blade is fl ush with the fl at bottom of

the blade holder.

8.0 TROUBLESHOOTING

The Troubleshooting Chart is intended as a guide to help you

diagnose and correct various possible problems.

Only qualifi ed hydraulic technicians should troubleshoot and

service the nut splitter. For repair service, contact the Authorized

Enerpac Service Center in your area.

WARNING: Fully release hydraulic pressure and

disconnect hydraulic hose(s) from nut splitter cylinder

before performing any adjustments, repairs or

maintenance.

CAUTION: Piston retract spring and other internal parts

may eject from cylinder suddenly during disassembly.

To avoid personal injury, use caution if cylinder

disassembly is necessary. Cylinder disassembly and repairs

should be performed only by qualifi ed personnel.

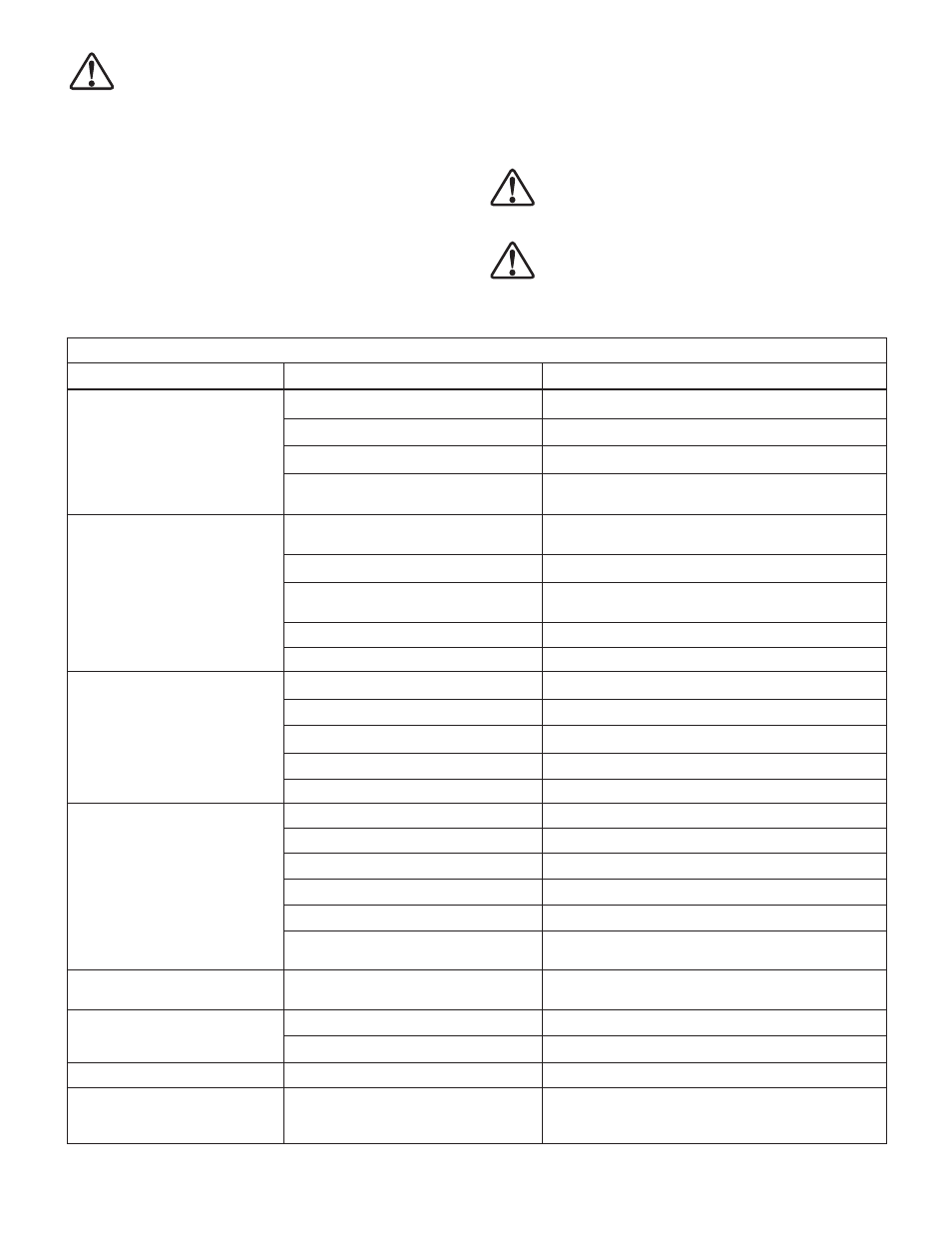

Troubleshooting Chart

Problem

Possible Cause

Action

1. Nut splitter cylinder will not

hold pressure.

Piston seal leaking.

Replace seal.

Coupler leaking.

Replace coupler.

Cylinder internal relief valve malfunction. Check relief valve and replace if required.

Hydraulic pump malfunction.

Check hydraulic pump for proper operation. Repair or

replace pump as required.

2. Nut splitter cylinder builds

pressure, but piston and blade

do not move or move only a

partial amount.

Pump reservoir not vented.

If using a vented pump, loosen vent/fi ll cap or vent

screw as required to provide venting.

Coupler not fully assembled.

Check couplers.

Both hoses not connected.

(double acting models only)

Be sure that both hoses are connected.

Piston at full stroke.

Allow piston to retract.

Blocked hose.

Replace hose.

3. Nut splitter cylinder will not

build pressure.

Pump release valve open.

Close pump release valve.

Piston seal leaking.

Replace seal.

Cylinder internal relief valve malfunction. Check relief valve and replace if required.

Insuffi

cient oil in pump.

Add oil to pump reservoir as required.

Coupler leaking.

Replace coupler.

4. Nut splitter cylinder will not

retract or retracts very slowly.

Loose coupler.

Check coupler and tighten if loose.

Restricted or blocked hose.

Replace hose.

Incorrect coupler being used.

Install correct coupler.

Incorrect hose being used.

Install correct hose.

Pump release valve closed.

Open pump release valve.

Broken or weak piston return spring.

(single acting models only)

Replace return spring.

5. Nut splitter builds full pressure,

but will not split nut.

(See Section 6.4 of instructions.)

(See Section 6.4 of instructions.)

6. Hose is diffi

cult to assemble.

Damaged coupler.

Replace coupler.

Internal pressure within hose.

Vent hose.

7. Frequent blade replacement.

Lubricant not used.

Use lubricant.

8. Leakage from nut splitter oil

bleed hole on underside of

blade holder.

Pressure above 10,000 psi [700 bar].

Release system pressure to allow cylinder internal

relief valve to reset.