0 description, 0 specifications 3.1 dimensions and capacities, 2 nut and bolt ranges – Enerpac NS-Series User Manual

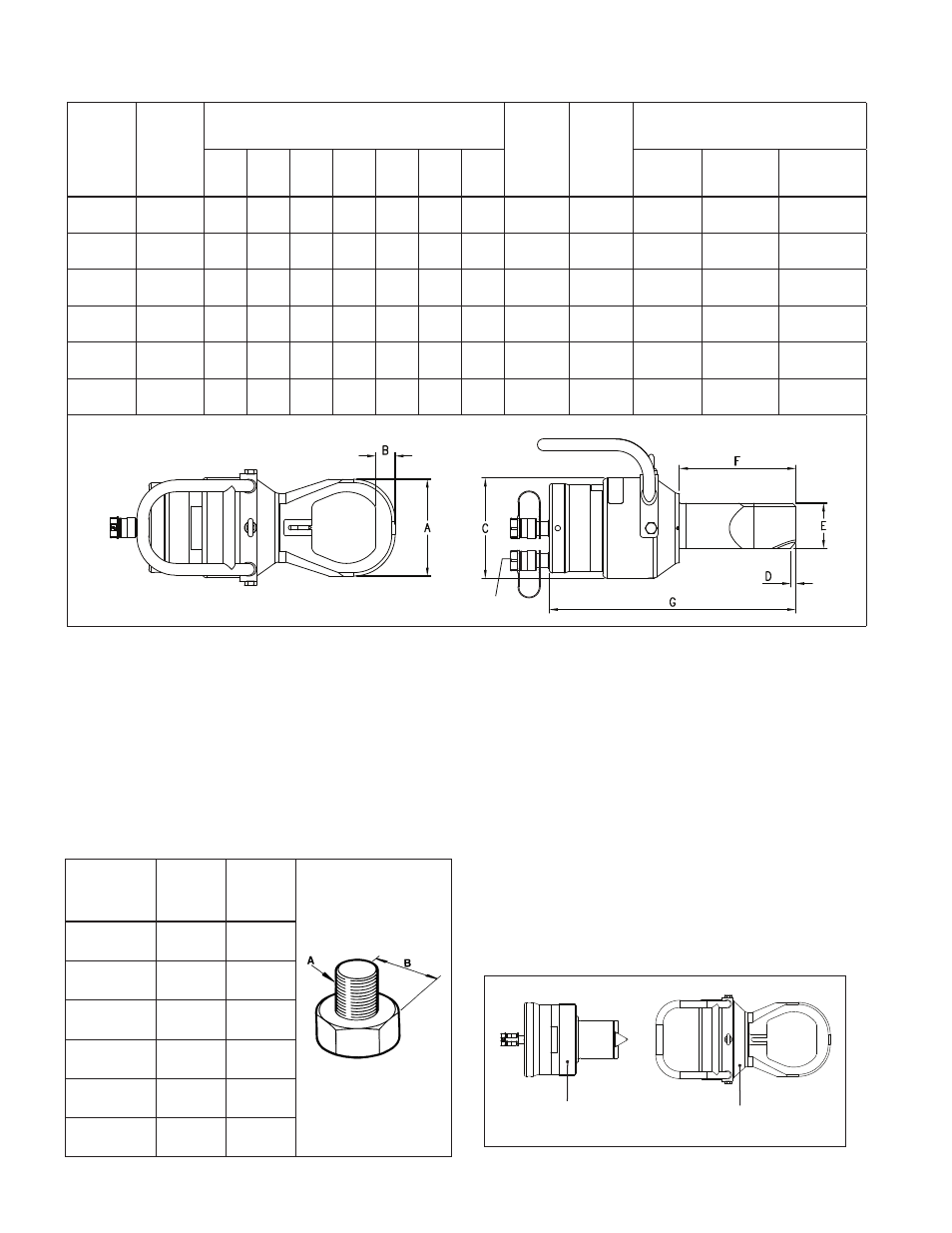

Page 3: Figure 2, nut splitter subassembly

3

Notes:

• The NS Series is available in both single and double acting

models. Single acting models use spring force to retract the

blade. Double acting models use hydraulic force to retract the

blade.

• A model number ending with “D” indicates that the nut splitter

(or cylinder sub-assembly) is double acting. Refer to Section 3.1

for model numbers and additional information.

• Both single and double acting models use the same NSH

series cutting heads shown in Section 3.1.

4.0 DESCRIPTION

The NS Series nut splitter is a hydraulically operated industrial

power tool, designed to quickly remove seized or heavily

corroded nuts from threaded studs.

See Figure 1 for an overview of NS nut splitter major features and

components.

A complete nut splitter consists of two separate subassemblies:

1) a single or double acting hydraulic cylinder and 2) a

matching cutting head designed for use with a specifi ed nut

size range. The replaceable cutting blade is installed in a blade

holder mounted on the shaft of the cylinder subassembly.

See Figure 2.

One cutting head is provided with each nut splitter. If desired,

additional cutting heads for diff erent nut size ranges can be

purchased separately from Enerpac.

Refer to sections 3.1 and 3.2 for nut splitter specifi cations and

additional information.

Cylinder

Subassembly

Cutting Head

Subassembly

Figure 2, Nut Splitter Subassembly

3.0 SPECIFICATIONS

3.1 Dimensions and Capacities

Nut

Splitter

Model

Number

Capacity

tons [kN]

Dimensions

inch [mm]

Weight

lb [kg]

Minimum

Pump Oil

Capacity

in

3

[cm

3

]

Additional Model Numbers

A

B

C

D

E

F

G

Cylinder

Sub-

Assembly

Cutting

Head Sub-

Assembly

Replacement

Blade

NS-7080

NS-7080D

103.2

[918]

5.2

[132]

1.1

[28]

7.1

[180]

0.3

[8.0]

3.2

[81]

7.3

[186]

16.2

[412]

81.4

[37.0]

23.0

[377.0]

NSC-70

NSC-70D

NSH-7080

NSB-70

NS-7085

NS-7085D

103.2

[918]

5.7

[145]

1.2

[30]

7.1

[180]

0.3

[8.0]

3.2

[81]

7.7

[196]

16.6

[422]

82.7

[37.5]

23.0

[377.0]

NSC-70

NSC-70D

NSH-7085

NSB-70

NS-7095

NS-7095D

103.2

[918]

6.3

[160]

1.3

[32]

7.1

[180]

0.3

[8.0]

3.2

[81]

7.9

[201]

17

[432]

84.9

[38.5]

23.0

[377.0]

NSC-70

NSC-70D

NSH-7095

NSB-70

NS-70105

NS-70105D

103.2

[918]

6.9

[174]

1.4

[35]

7.1

[180]

0.4

[9.0]

3.2

[81]

8.2

[209]

17.5

[443]

87.1

[39.5]

23.0

[377.0]

NSC-70

NSC-70D

NSH-70105

NSB-70

NS-110115

NS-110115D

192.5

[1712]

7.4

[189]

1.4

[36]

9.2

[234]

0.1

[3.7]

4.4

[111]

9.2

[234]

18.6

[472]

151.6

[68.8]

50.0

[819.5]

NSC-110

NSC-110D

NSH-110115

NSB-110

NS-110130

NS-110130D

192.5

[1712]

8.6

[219]

1.6

[41]

9.2

[234]

0.1

[2.5]

4.4

[111]

9.5

[242]

19.4

[493]

158.3

[71.5]

50.0

[819.5]

NSC-110

NSC-110D

NSH-110130

NSB-110

Double Acting Only

Note: A model number ending with “D” indicates double acting.

3.2 Nut and Bolt Ranges

A

B

Cutting Head

Subassembly

Model Number

Bolt Range

inch [mm]

Hexagon

Nut Range

inch [mm]

NSH-7080

1.75-2.00

[M45-M52]

2.75-3.13

[70-80]

NSH-7085

1.75-2.25

[M45-M56]

2.75-3.50

[70-85]

NSH-7095

1.75-2.50

[M45-M64]

2.75-3.88

[70-95]

NSH-70105

1.75-2.75

[M45-M72]

2.75-4.25

[70-105]

NSH-110115

2.75-3.00

[M76-M80]

4.25-4.63

[110-115]

NSH-110130

2.75-3.50

[M76-M90]

4.25-5.38

[110-130]