Det-Tronics U9500 Infiniti Gas Transmitter User Manual

Page 25

95-8444

23

10.1

Calibration Gas Sources

For optimum performance, only use Det-Tronics

calibration gases.

iMPOrTanT

The calibration gas concentration setting must

match the concentration of the gas used to

perform the calibration (printed on label of

calibration gas cylinder).

For PointWatch calibration,

use only 50% LFL

concentration calibration gas of the same type as

selected by the PointWatch gas selection switch. Refer

to the PointWatch instruction manual for details.

For catalytic sensor calibration,

most applications

require the use of 50% LFL calibration gas matching the

type of gas to be detected. If a matching calibration gas

type is not available, a conversion K-factor must be used.

Refer to the “Catalytic Sensor Calibration” section in this

manual for details.

For toxic gas sensor calibration,

the calibration gas

type must match the sensor cell type. The calibration

gas concentration should be one half of the full scale

measurement range of the sensor in use.

For oxygen sensor calibration,

normal ambient air may

be used for span calibration if it is known to be clean and

not depleted of O

2

(21% vol.). Compressed clean air is

available from Det-Tronics if required. It is not necessary

to utilize an O

2

free gas such as compressed nitrogen

to calibrate the O

2

sensor zero level. An electronic zero

switch is provided within the C7065E sensor housing for

this function. Refer to the O

2

sensor instruction manual

for details.

Important Calibration Notes

• Ensure that the transmitter is properly programmed

for the gas concentration being used for calibration.

(See the “Setup” section.)

• Ensure that only clean air is present at the sensor prior

to entering the calibration mode. If the possibility

of background gases exists, purge the sensor with

clean air to ensure accurate calibration.

• Ensure that the concentration of the calibration

gas matches the calibration gas setting. Typically,

calibration gas concentration equal to 50% full scale

is used.

• If the calibration procedure is not completed or

if the sensitivity of the sensor has deteriorated to

the extent that calibration cannot be successfully

completed, a fault will be generated and the system

will automatically revert back to the former calibration

settings (after 10 minutes or when the gas level drops

below the lowest setpoint). If a successful calibration

cannot be accomplished, replace the sensor and the

hydrophobic filter (if used) and re-calibrate.

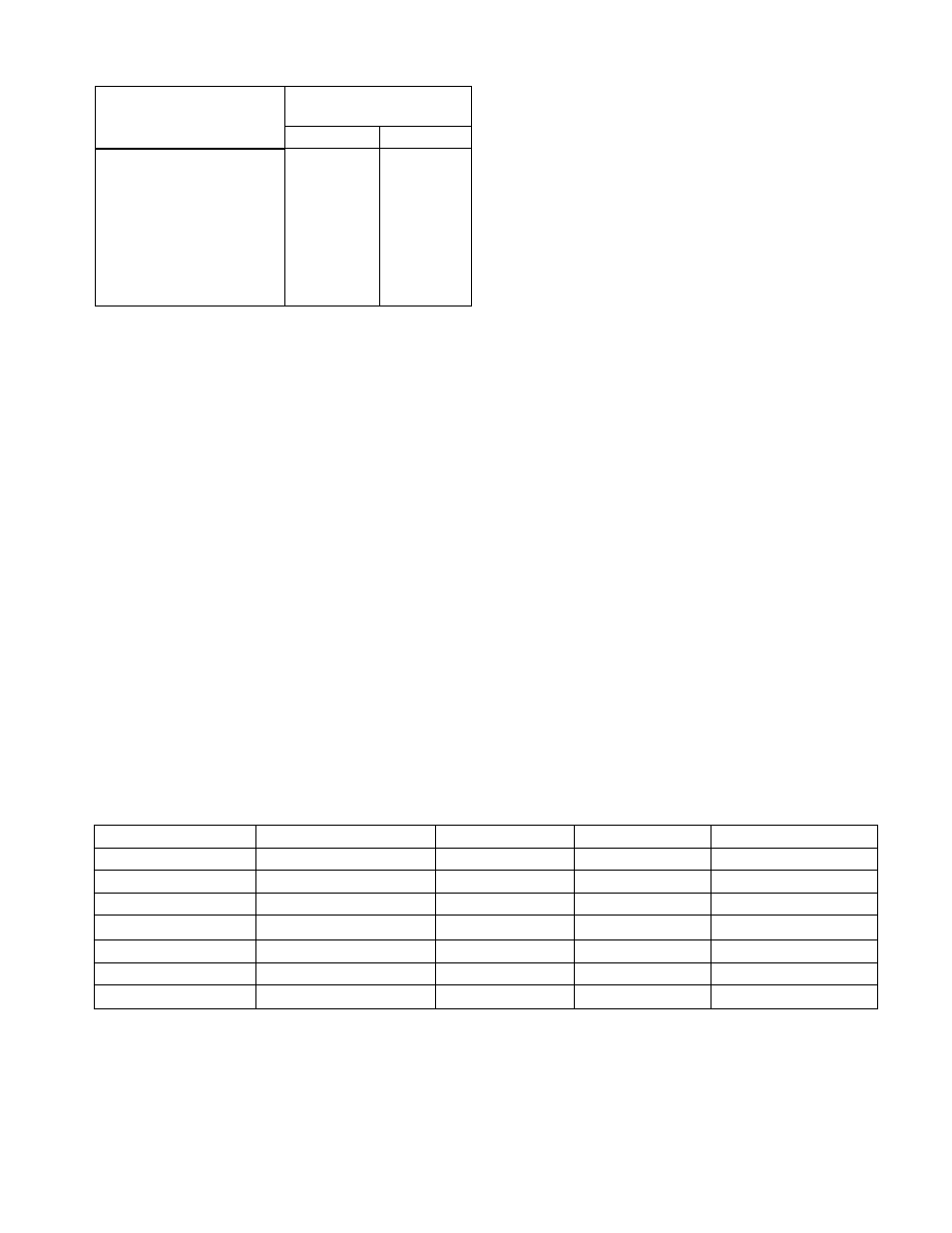

Table 11—Recommended Sensor Calibration Methods

Sensor Type

After 1 Hour Warm-up

After 24 Hours

After 1 Week

Every 90 Days

PointWatch

*

Opt

Opt

Opt

Catalytic

Req

Req

Req

Req

H

2

S Electrochemical

Req

Opt

Opt

Opt

Chlorine

Req

Req

NR

Req

Oxygen

Req

Opt

Opt

Opt

Carbon Monoxide

Req

Opt

Opt

Opt

Sulfur Dioxide

Req

Opt

Opt

Opt

Req = Required

Opt = Optional

NR = Not Recommended

* = Optional for methane. Must be calibrated if gas selection setting other than methane is used.

Table 12—Recommended Frequency of Calibration for Det-Tronics Sensors

Sensor

Calibration

Method

Auto

Manual

Combustible Catalytic (Ex)

X

H

2

S

X

CO

X

PointWatch (HC)

X only

O

2

X only

Cl

2

X only

SO

2

X only