COATS 7xxx Series Tire Changer User Manual

Page 28

24 •

Important: Always read and follow operating instructions.

Duckhead (Mount/Demount Tool)

Adjustment

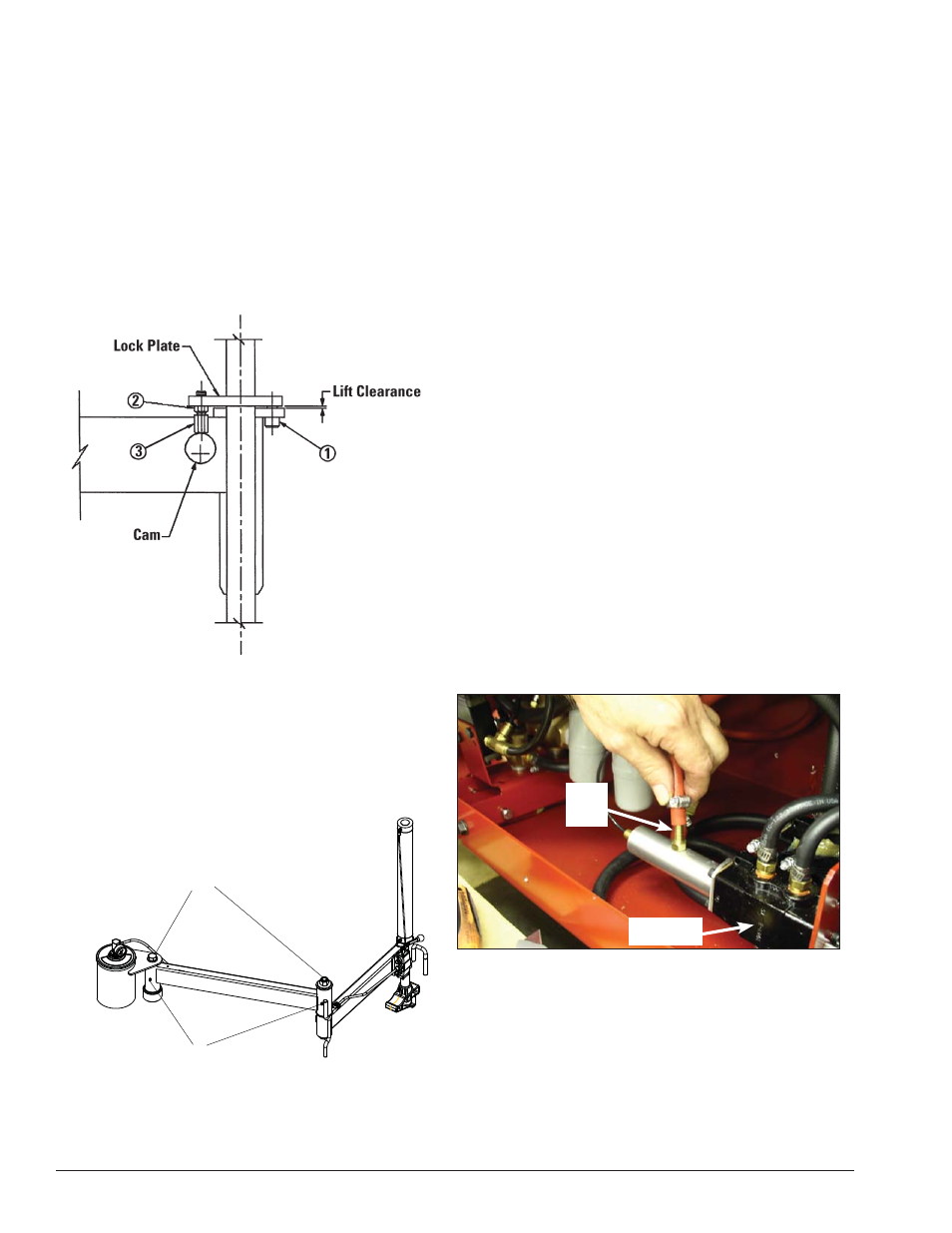

To Adjust Tool Head Lift

Shoulder screw (ref.1) sets the tool head lift for

metal duckhead mount/demount tools – no adjustment

required. Place shim 85606345 on screw if using a

plastic duckhead mount/demount tool.

To Adjust Lock Tightness

With lock handle unlocked, loosen jam nut (ref. 3) and

adjust pin (ref. 4) until a slight firmness is obtained, then

tighten jam nut and check. Also recheck tool head lift at

this time.

Robotic Arm Maintenance

1.

Grease the Robo Arm™ to maintain smooth rota-

tion. Grease fittings have been provided at the pivot

joints.

2.

Check bolt torque periodically at pivot joints. Proper

torque is 240 ft. lbs.

Oil Injector Maintenance (if equipped)

The oil injector requires servicing at least annually.

The oil level in the oil reservoir tank should be checked

regularly.

Add oil to oil reservoir tank when fluid level is a quarter

full or below. Remove cap from the oil reservoir tank

and add Chevron Regal

®

R & O 32 oil to full line (air tool

oil is an acceptable substitute). Replace cap and clean

up any spilled oil.

Important: An air lock will form if the hose between

the reservoir and injector is ever empty of oil. In this

case, after filling the reservoir tank, the line must be

bled of air at the injector connection as follows:

1.

Disconnect all power sources, both air and electric-

ity inputs. Allow any stored air in the reservoir to escape

by depressing the inflate pedal.

2.

Remove the side panel and locate the oil injector.

3.

Prime the oil injector.

a. Oil Injector With Bleeder Screw

Loosen bleeder screw until oil drips from screw and

all air is relieved from the oil line hose. Retighten

the bleeder screw.

b. Oil Injector Without Bleeder Screw

Remove the oil line hose from the injector barb fit-

ting. Allow air to escape from the hose by lowering

the hose end below level of reservoir until oil is

present. Drip oil into hose barb fitting on injector

until barb fitting is full. Reinstall oil line hose onto

oil injector barb fitting.

4.

Reconnect air/electric sources and cycle the clamp

control pedal a few times checking for oil and air leaks.

5.

Test the machine for full function before returning

the machine to operation.

6.

Monitor oil consumption to ensure oil is being used

in system.

Maintain Bolt Torque

at 240 ft. lbs.

Grease Fittings

Injector

Barb

Fitting

Clamp Control

Pedal Valve