Ul9010 ultra-lok, Tool, Maintenance – BAND-IT UL9010 Ultra-Lok Tool User Manual

Page 12

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

Ph: 1-800-525-0758

Fax: 1-800-624-3925

Document # P44987 Rev. N

© Copyright

BAND-IT-IDEX, Inc. 2011

All rights reserved

www.BAND-IT-IDEX.com

Page 12 of 14

UL9010

Ultra-Lok

Tool

Maintenance

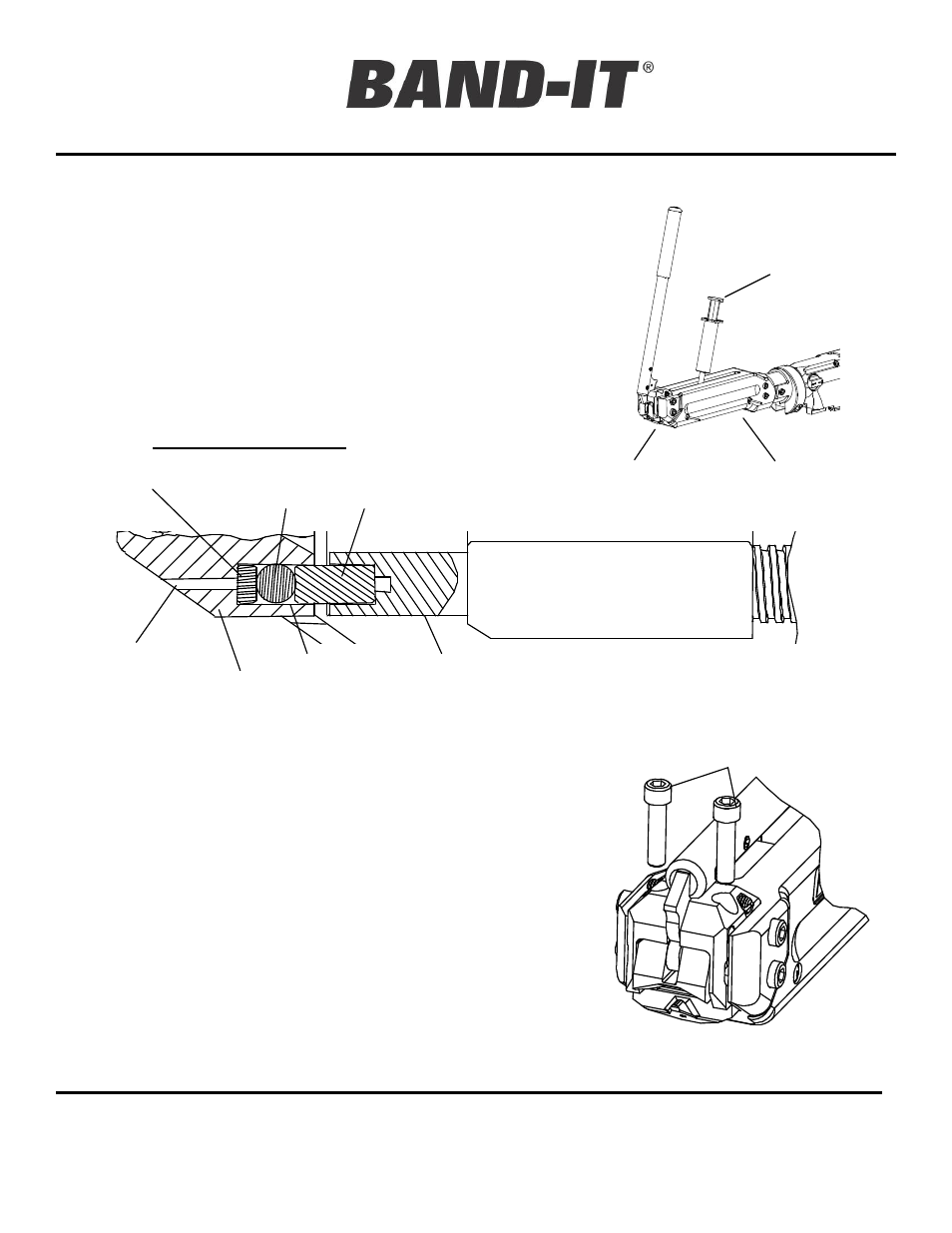

1. Lubricate tension screw with molybdenum disulfide lubricant or

equivalent approximately every 500 clamps.

Make sure the tension block is all the way forward against the tool

head. Insert tip of the Lubricating syringe into slot on top of tool

body. Press the tip against the tension screw just behind the tension

block and squeeze out approximately ½” long bead of lubricant.

Remove syringe, and actuate tool without a clamp a couple of times

to spread lubricant evenly on tension screw.

To order more lubricant, specify BAND-IT #C23199

2. Every 500-1000 clamps, depending on tension setting, inspect and

repack front bearing with same lubricant. Turn load bearing tip and

small bearing tip over for a new bearing surface.

3. To gain access to bearing components: With the tension body

already separated from the power drill, remove blade mounting

screws (2 places) and slide blade free. Paper clip may be used to

push bearing components out of blade. Wipe lubricant from all

components and examine for wear. If ball or bearing tips appear

heavily worn, replace with new parts. Note: ¼” ball is made from

hard tungsten carbide material, do not replace with regular ball

bearing. (A smooth indention from ball in the bearing tips is normal)

4. To re-assemble bearing components: wipe blade cavity clean. Push

small bearing tip into blade cavity. Apply lubricant to ball and push

into blade cavity and fill remaining space with lubricant. Push load

bearing tip firmly into blade cavity, some lubricant will be squeezed

out. Re-attach blade to tool head, making sure that Load Bearing

Tip extends into tension screw. While turning blade mounting

screws into blade, push on blade rearwards. Tighten screws to

approximately 120 in-lbs.

5. When replacing worn blade follow instructions above to properly re-

assemble bearing components.

Tool

body

Tool head

Item 1

Lubricating

Syringe

Reorder

#C23199

Bearing Lubrication Detail

Small Bearing Tip

Item 14

¼” Ball

Item 15

Load Bearing Tip

Item 16

Access hole to push

out components (use

paper clip)

Blade

Item 2

Blade Cavity

(must be packed

with lubricant)

Tension Screw

Item 7

Blade mounting

screws

Item 21