It6000-ab, Troubleshooting, 16 of 38 – BAND-IT IT6000-AB 3/8 Tie-Lok Tool User Manual

Page 16: 3/8” tie-lok, Tool

Document # I17796 Rev F

© Copyright

BAND-IT-IDEX, Inc. 2009

All rights reserved

www.BAND-IT-IDEX.com

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street Denver, CO 80216-0307 USA

P: 1-800-525-0758 F: 1-800-624-3925

16 of 38

IT6000-AB

3/8” Tie-Lok

®

Tool

Tool fails to fully tension clamp:

Failure to fully tension the clamp can be caused by a variety of factors. The two most

common factors are: incorrect tension pressure and problems in the Tension Block

Assembly.

• Check tension pressure setting on Tension Pressure Gauge of Air Controller Module.

Adjust pressure per the settings in the Setup & Assembly Instructions section found on

(pages 9-11).

• After air pressure settings are verified or corrected, if failure to fully tension clamps

continues, evaluate the clamp tail dimple pattern. If elongated dimples are present, the

problem may be with the Tension Block.

If a problem is indicated, follow the instructions on page 24 to remove the tension block

assembly.

Examine the Tension Block components for excess lubrication. Refer to lubrication

instructions on pages 24, 27.

If dirt or debris is visible, follow the cleaning instructions on page 24.

Examine the Tension Block and Gripper for wear (see below).

If excessive wear is determined, follow the instructions on page 24 to replace the worn

parts.

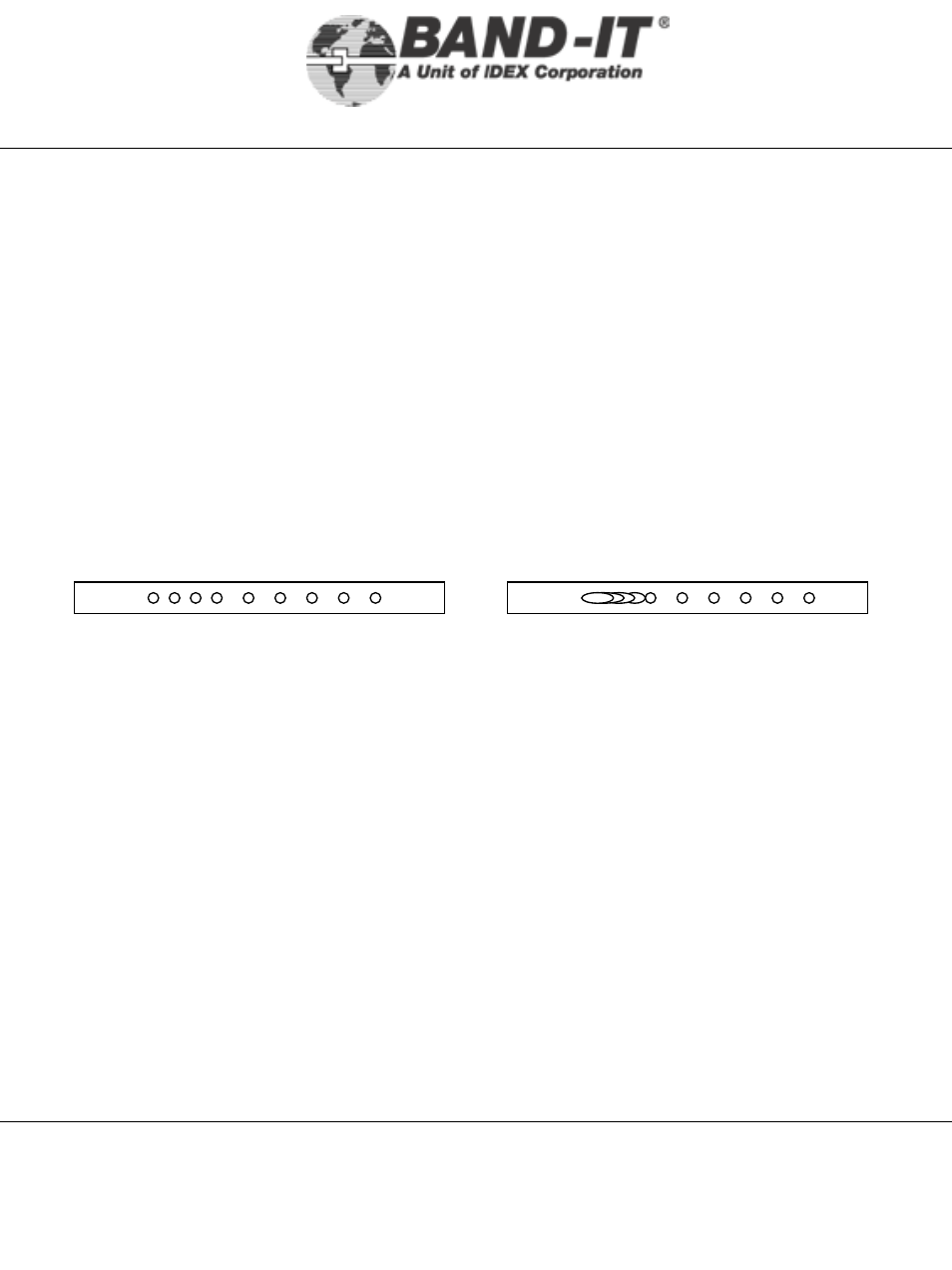

Normal clamp tail

dimple pattern.

Clamp tail dimple pattern indicates

problem in the tension block

assembly.

Troubleshooting