It3000-ab, Troubleshooting matrix, 19 of 28 – BAND-IT IT3000-AB 1/4 Ultra-Lok Tool User Manual

Page 19: 1/4” ultra-lok tool

Document # I17793 Rev D

© Copyright

BAND-IT-IDEX, Inc. 2009

All rights reserved

www.BAND-IT-IDEX.com

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street Denver, CO 80216-0307 USA

P: 1-800-525-0758 F: 1-800-624-3925

19 of 28

IT3000-AB

1/4” Ultra-Lok Tool

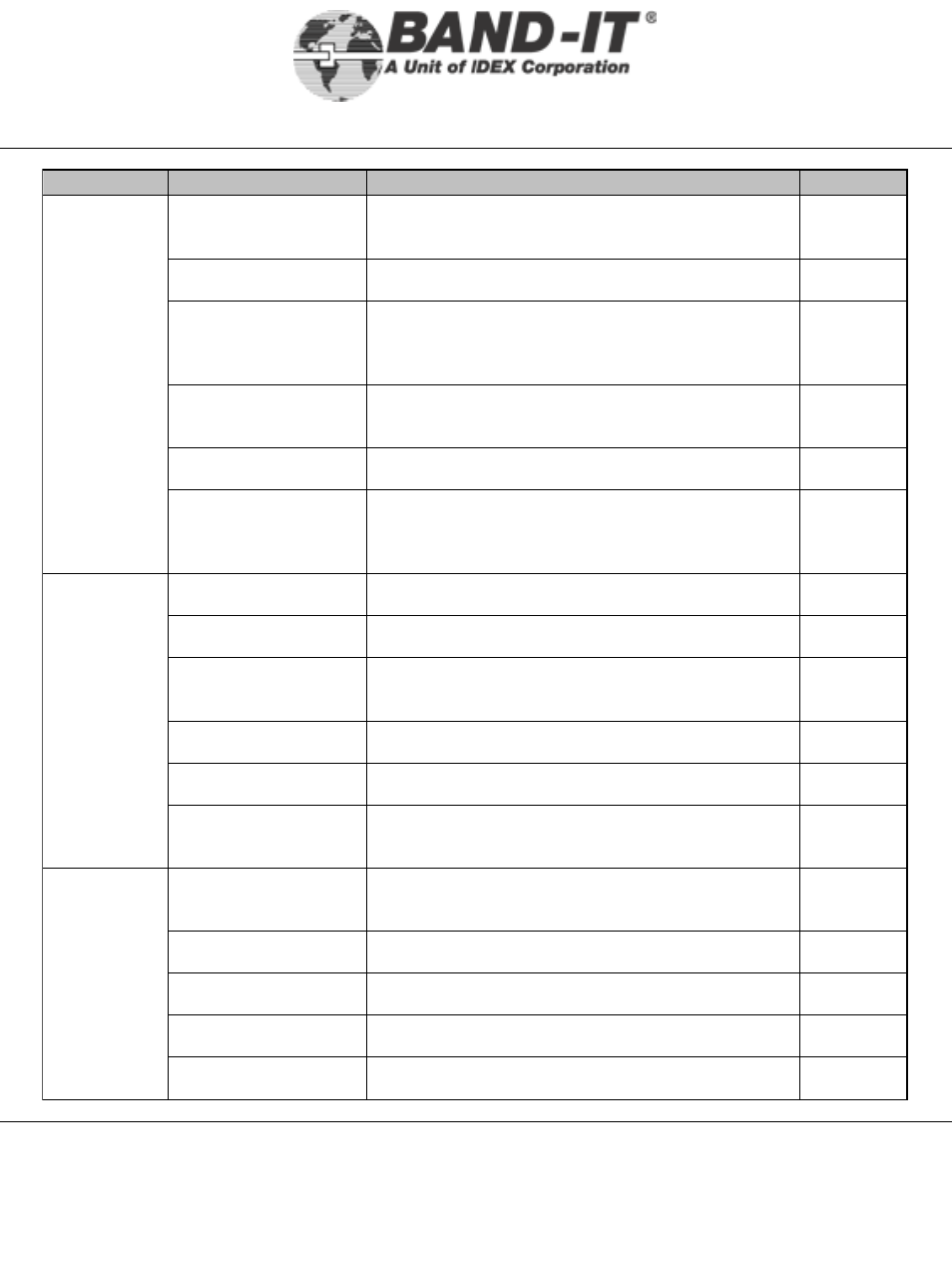

Symptom

Probable cause

Recommended Fix

Page

Linkage components

damaged, causing

interference

Remove tool left side body and verify linkage mechanism.

Remove and replace damage as required or contact BAND-

IT.

27

Cut-off cylinder seal

damaged or leaking

Remove left side tool body and verify seal integrity

*

Cut off pneumatic air leak

Verify Coiled Hose Assembly is free of air leaks. Remove

handle cover and inspect for leaks on gray anodized valve

assembly and red valve assembly. Inspect for leaks in

pneumatic system.

*

Water or oil in pneumatic

lines.

Purge pneumatic lines and red four way valve assembly.

Install a desiccant air dryer or similar equipment which meets

tool requirements).

4

Screws holding Cutter Knife

Pin too long or loose

Verify proper length screws and Cutter Knife Pin seated

properly.

23

Coiled hose line is reversed

(i.e. cut off pressure is

actually going to tension

cylinder.

Verify coiled hose air line from right side of control module

enters bottom fitting on tool.

4,5,7

Improper tool use

Verify operator properly trained and familiar with tool manual.

5,7,8,14

Tension setting too low

Adjust Air Controller Module's tension setting per instructions.

4

Improper buckle location or

application

Locate buckle on smallest radius area. Buckle must be

supported underneath during application. Contact BAND-IT

for application verification / recommendation.

15

Tool cuts clamp tail before

reaching full tension.

Verify timing. If required remove right side handle and adjust

Timing Valve. Replace if damaged.

28

Worn Cutter Knife/ Cutter

Blade

Remove and replace Cutter Knife and Cutter Blade. Refer to

maintenance schedule.

17

Air leaks when trigger is not

activated

Listen for air leaks. Check red valve, Air lines, and replace as

required. No air leaks allowed. Remove and replace as

required or contact BAND-IT.

Contact BAND-

IT for

assistance

Control Module air pressure

valve is in "off" position.

Rotate Control Module valve to open position. Verify gauges

read air pressure.

5

Pinched coil hose line

Loosen fitting on coiled hose assembly where it enters tool

body.

4,7

Kinked or pinched air line

Remove right side handle and inspect air lines. Remove and

replace as required.

28

Tension piston interference

with hanger screw holes.

Loosen Hanger Screw on top of tool. Thread engagement

cannot exceed .125 in.

11

Quick disconnect fittings

not positively engaged.

Disconnect and firmly reconnect.

5,8

Tool will not

operate when

trigger is

depressed

Loose clamp

after cut-off

Tool will not cut

off clamp tail -

Continued.

Troubleshooting

Matrix