Stand pipe mounting, Stilling pipe mounting – APG IRU-9400 user manual User Manual

Page 9

Rev. B1, 3/10

IRU Series

9

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • [email protected]

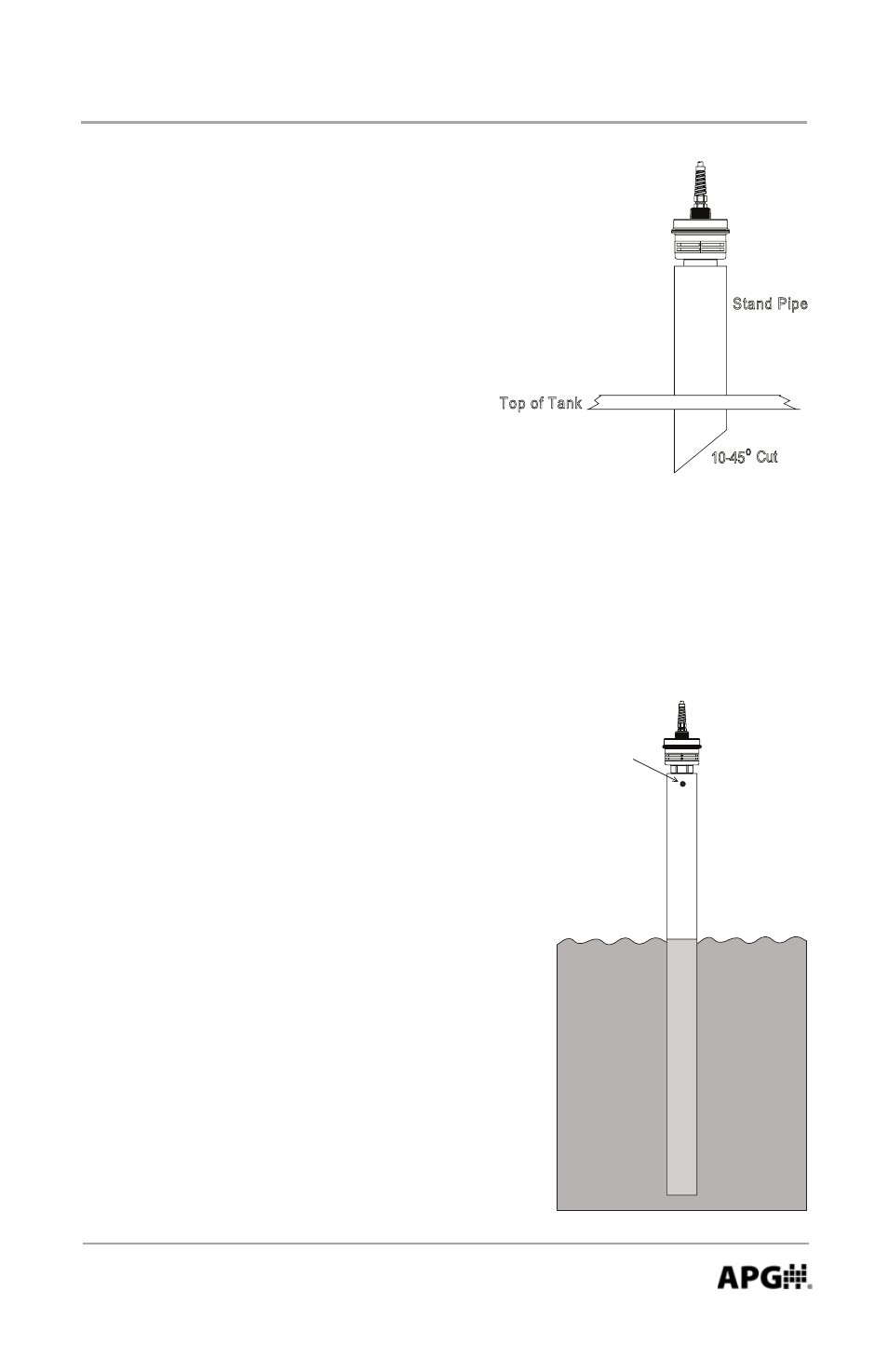

Stand Pipe Mounting

Stand pipes are used to provide headroom

at the top of a tank when the target is

expected to come closer to the sensor

than the minimum blanking distance.

It’s very critical that the stand pipe be

installed perpendicular to the target. This

is especially important on longer range

applications. The pipe must have smooth

walls (no joints) and no burs or obstructions.

If possible, cut the end of the pipe at a 10°-

45° angle (see drawing). Use the largest

diameter pipe and shortest length possible. As a general rule, the diameter of the

pipe should be 1/2 the length. The pipe ID must remain the same through it’s

entire length.

Stilling Pipe Mounting

Stilling pipes provide access to difficult

areas and help eliminate problems with

foam. The pipe must have smooth walls (no

burs or joints). Because the sound waves

will concentrate and propagate down the

inside walls of the tube, any irregularities

on the tube walls may produce echo returns

and cause false readings. Stilling pipes are

limited to liquid targets that will not leave

heavy deposits on the tube walls. Because

the sound waves are confined inside the

pipe, it is usually necessary to greatly

reduce the sensors sensitivity and pulses

settings. A vent hole must be provided at

the top of the pipe. Be sure to keep the

vent hole inside of the blanking area.

Top of Tank

Stand Pipe

10-45

o

Cut

(when possible)

Vent Hole