Npt mounting – APG IRU-9400 user manual User Manual

Page 8

IRU Series

Rev. B1 3/10

8

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • [email protected]

4. Always mount above the highest anticipated target level by at least the

published minimum blanking distance. If a target enters into the blanking

area, error in the detection will occur. It is always advisable to allow for

sufficient headroom to ensure that the target does not enter the blanking

area.

5. Generally it is advisable to mount the sensor away from any vessel fill

spouts. However, if heavy foam is expected, it is often helpful to mount the

sensor near a fill spout where the foam is being dispersed.

6. Avoid mounting the sensor in the direct center of a tank with a significantly

domed top. A domed top can act as parabolic dish, amplifying small

undesired signals that may be present inside the tank.

7. Avoid mounting the sensor in close proximity to tank walls, especially

on tanks with corrugated walls or in applications where product buildup on

the tank walls may occur.

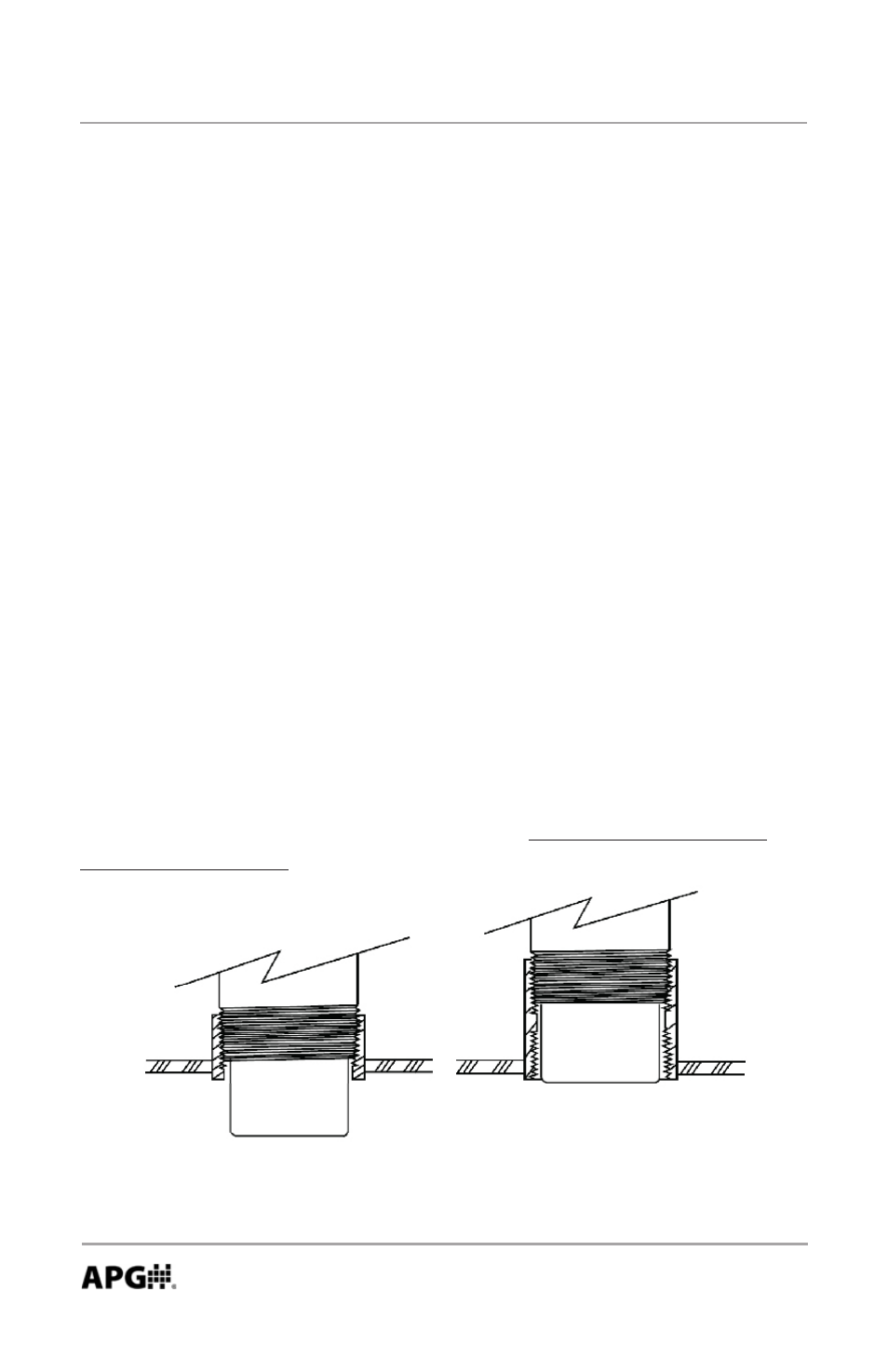

BEST GOOD

NPT Mounting

A half-coupler is preferable to a full-coupler to help ensure that the sensor face

extends below the mounting fixture. The coupler must be aligned so that the

sensor face is perpendicular to the target surface. Thread the sensor into the

coupler only hand tight.