8 swing motor, Preparation before disassembly, Swing motor -43 – JLG 450A_AJ Series II Service Manual User Manual

Page 83: Preparation before disassembly -43, Swing motor - cutaway -43

SECTION 3 - CHASSIS & TURNTABLE

3121290

– JLG Lift –

3-43

3.8

SWING MOTOR

IF HYDRAULIC SYSTEM FLUID BECOMES OVERHEATED [IN EXCESS OF 200°F

(93.3°C)], SEALS CAN SHRINK, HARDEN, OR CRACK AND LOSE THEIR SEALING

ABILITY.

Preparation Before Disassembly

PETROLEUM-BASE SOLVENTS ARE FLAMMABLE. BE EXTREMELY CAREFUL

WHEN USING ANY SOLVENT. EVEN A SMALL EXPLOSION OR FIRE COULD CAUSE

INJURY OR DEATH.

WEAR EYE PROTECTION AND COMPLY WITH OSHA OR OTHER MAXIMUM AIR

PRESSURE REQUIREMENTS.

NEVER STEAM OR PRESSURE WASH HYDRAULIC COMPONENTS. DO NOT FORCE OR

ABUSE CLOSELY FITTED PARTS.

• Before you disassemble motor or any of its components

read this entire section. It provides important information

on parts and procedures to service motor.

• Before disconnecting and removing motor, thoroughly

clean off all outside dirt, especially from around fittings

and hose connections. Remove rust or corrosion from cou-

pling shaft.

• Remove coupling shaft connections and hose fittings and

immediately plug port holes and fluid lines.

• Remove motor from system, drain fluid, and move it to a

clean work surface.

• Clean and dry motor before disassembly.

• Keep parts separate to avoid nicks and burrs.

• Discard all seals and seal rings as they are removed from

motor. Replace all seals, seal rings and damaged or worn

parts with OEM approved service parts.

• Clean all parts except seals in clean petroleum-based sol-

vent. Dry with compressed air.

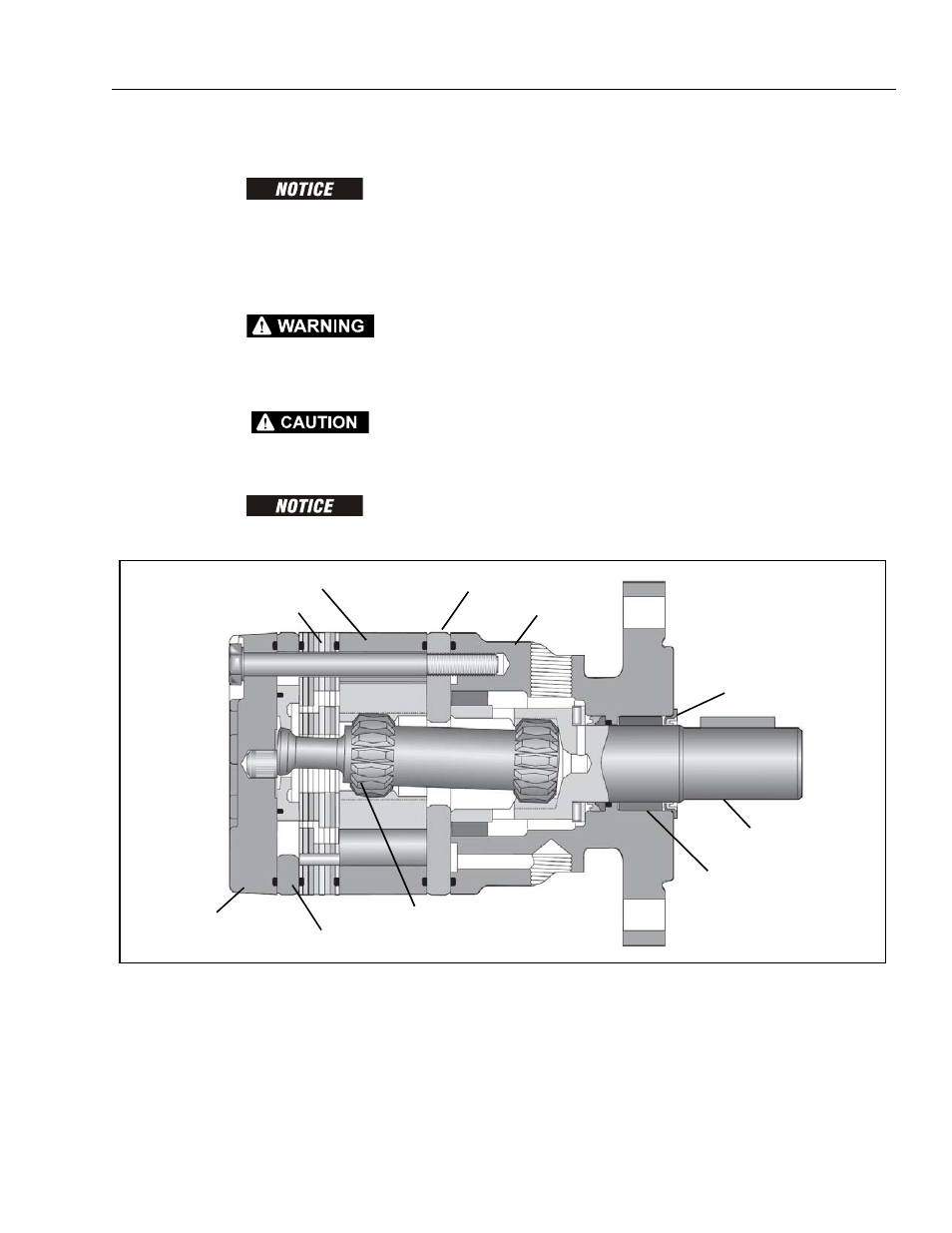

Figure 3-39. Swing Motor - Cutaway

Coupling Shaft

Outer Shaft Seal

Bearing

Housing

Matched Rotor Set

End Cover

Matched Commutator Set

Manifold

Drive Link - 12 Tooth Splines

Wear Plate