Wheel installation, Wheel installation -2, Wheel lug nut tightening sequence -2 – JLG 450A_AJ Series II Service Manual User Manual

Page 42: Wheel torque chart -2

SECTION 3 - CHASSIS & TURNTABLE

3-2

– JLG Lift –

3121290

Wheel Installation

WHEEL NUTS MUST BE INSTALLED AND MAINTAINED AT PROPER TORQUE TO

PREVENT LOOSE WHEELS, BROKEN STUDS, AND DANGEROUS SEPARATION OF

WHEEL FROM AXLE. USE ONLY NUTS MATCHED TO CONE ANGLE OF WHEEL.

Tighten lug nuts to proper torque to prevent wheels from

coming loose. Use a torque wrench to tighten fasteners. If you

do not have a torque wrench, tighten fasteners with a lug

wrench, then immediately have a service garage or dealer

tighten lug nuts to proper torque.

OVER-TIGHTENING WILL BREAK STUDS OR PERMANENTLY DEFORM MOUNT-

ING STUD HOLES IN WHEELS.

1.

Start all nuts by hand to prevent cross threading. DO

NOT use a lubricant on threads or nuts.

2.

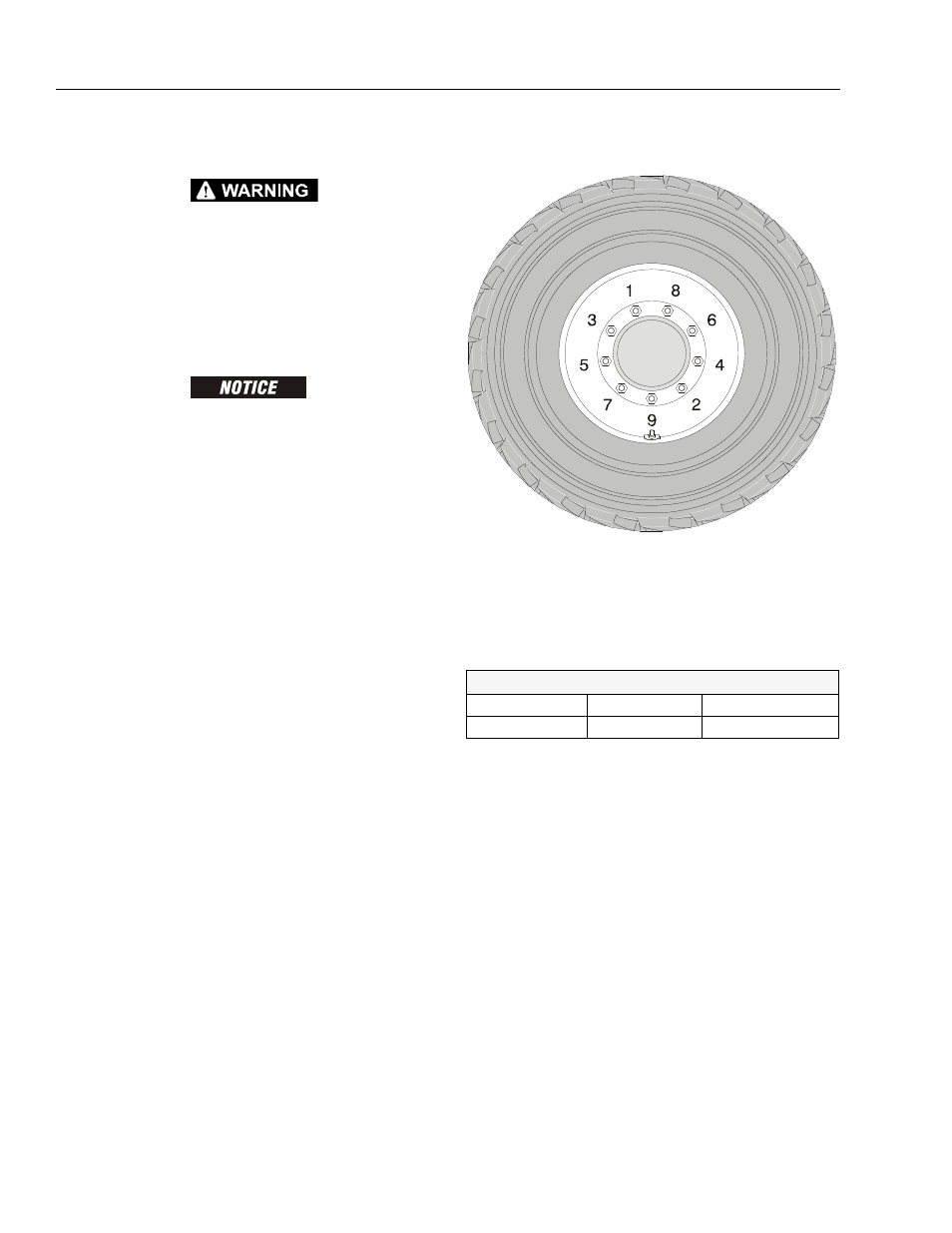

Tighten nuts in the following sequence:

Figure 3-1. Wheel Lug Nut Tightening Sequence

3.

Torque wheel nuts after first 50 hours of operation and

after each wheel removal. Check torque every 3 months

or 150 hours of operation.

Table 3-1. Wheel Torque Chart

TORQUE SEQUENCE

1st Stage

2nd Stage

3rd Stage

40 ft-lb (55 Nm)

100 ft-lb (130 Nm)

170 ft-lb (255 Nm)