Aerovent IM-201 User Manual

Page 9

Aerovent IM-201

9

6.8 SETTING MAXIMUM PITCH ON FPAC

& FPMC FANS

If it should become necessary to adjust the maximum

blade pitch on thee fans, proceed as follows:

1. Remove vane access section as per Section 5.7.

2. Release the two lock nuts on each stud (10) to allow a

change in their position.

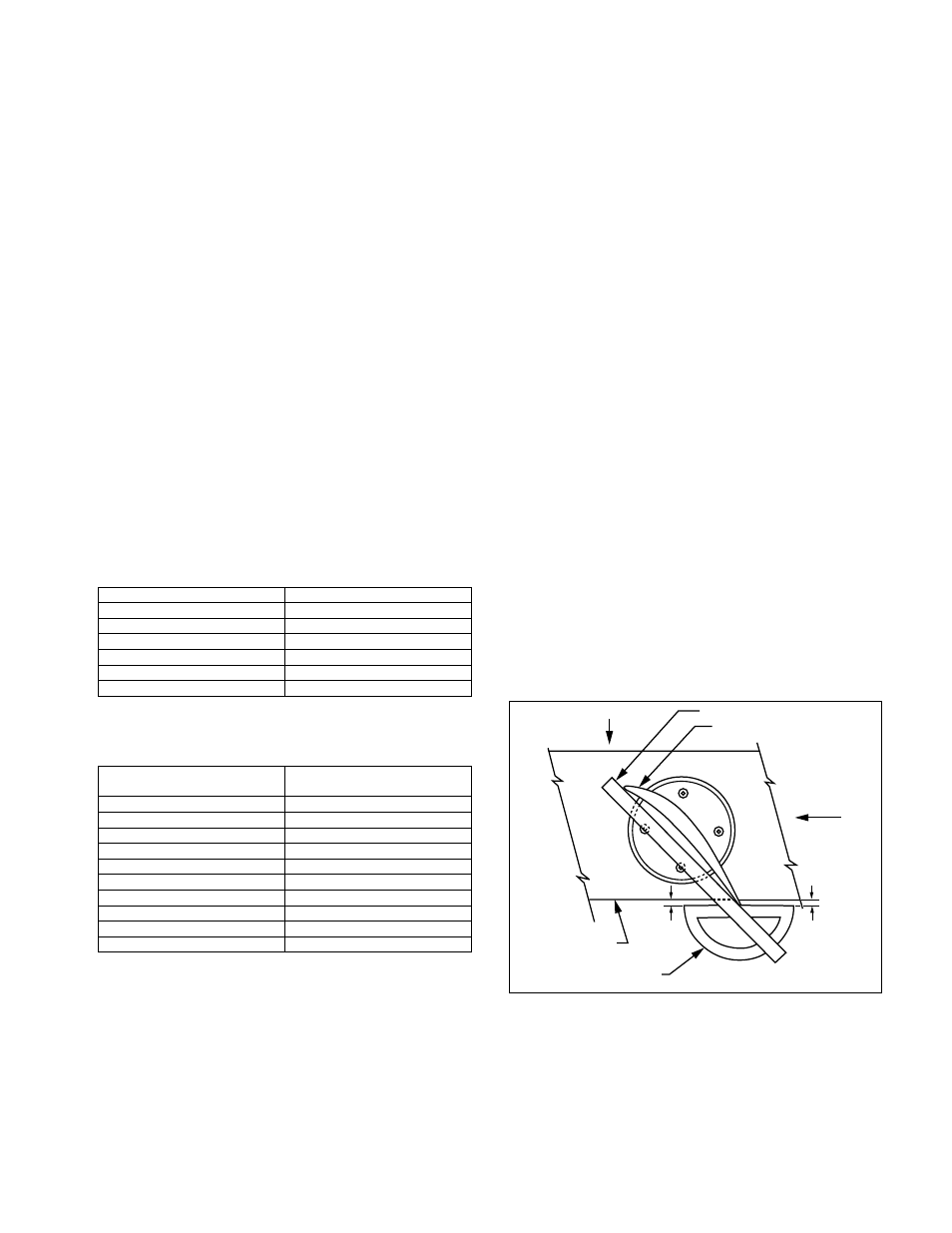

a. Set a protractor at the desired blade angle, 45°-47°, etc.

b. Bring fan to maximum pitch. Have the nuts on the studs

at same distance to start (item 21, near hub on Figure 6

in the AXICO instruction manual).

c. Check angle by placing the blade of the protractor

(scale) across the root (base) of the blade. When the

proper angle is found, the base of the protractor should

be parallel to the edge of the fairing. See Figure 5.

d. Adjust by turning stop nut (#21). Be sure that both

springs are compressed solid at the same time or the

spider will hang up on the hub.

NOTE: The fairing is scribed with a line that represents the

maximum blade angle that was set at the factory. This mark

can be used as a reference to check the angle. Factory blade

angle is indicated on nameplate.

CAUTION: Do not set maximum pitch stops at a blade angle

higher than 55°.

6. Tighten each locking nut.

7. Reassemble the vane access section.

6.9 MINIMUM PITCH SETTING

Aerovent AXICO fans may have minimum pitch set-

ting accomplished by use of two extended bolts in the dia-

phragm cover. This may be used to prevent the flow of any

system from going below a certain specified minimum.

Size 125 and larger have minimum pitch stops as stan-

dard set, if not otherwise specified, to 0 flow. Consult factory

for specific details on specific fans.

Figure 5.

Protractor Blade Scale

Base of Blade

Rotation

Airflow

Protractor Base

Fairing Edge

=

=

c. Replace the nuts on the studs, maintaining the position

recorded when they were removed. Tighten each jamb

nut to 24 ft-lbs.

6.5 ROTOR INSTALLATION

If the rotor has been removed from the shaft, obvious-

ly it must be put back in place prior to attaching the diaphragm

cover to hub cover as described above. To install the rotor on

the shaft, proceed as follows:

1. Clean fan shaft with solvent and apply a film of grease.

Locate key in keyway.

2. Slide rotor on fan shaft.

NOTE: It may be necessary to use a bar and a

1

∕

2

"-13 UNC

stud threaded into the motor shaft with a nut to pull the

rotor on the shaft.

3. Clean bolt and shaft threads and prime with Loctite grade

T primer. Blow out internal threads with air and allow to

air dry 5 minutes. Apply Loctite 242 to threads.

4. Install washer and bolt and torque to 50 ft-lbs for

1

∕

2

" bolt;

15 ft-lbs for

3

∕

8

" bolt.

5. Proceed with remainder of assembly depending on fan

type per Section 6.4.

6.6 MOTOR BOLT TORQUE

Motor bolts should be torqued to the following speci-

fications. Remember that it is not possible to check a torqued

bolt unless it is loosened first, as torque must be applied evenly

until the desired torque is reached. To tighten further after

a given torque value has been reached requires much more

torque to get the nut started than will be required to keep

tightening it, so the desired final torque must be reached in

one movement. All bolts are grade 5.

6.7 MINIMUM BLADE TIP CLEARANCE

The following dimension is the minimum clearance

between the tip of any blade and the fan case.

BOLT SIZE

TORQUE (FT-LBS)

5

⁄

16

-18

13

3

⁄

16

-16

27.5

1

⁄

2

-13

75

5

⁄

8

-11

150

3

⁄

4

-10

240

7

⁄

8

-9

380

FAN SIZE

MIN. TIP

CLEARANCE (IN.)

071

.030

080

.030

090

.034

100

.038

112

.043

125

.049

140

.055

160

.063

180

.072

200

.080