Aerovent IM-201 User Manual

Page 2

2

Aerovent IM-201

2.2 LIFTING

Aerovent fans should be lifted using slings. Note that

on AXICO fans the slings should be placed under the skids,

and spreader bars used as required. Under no circumstances

should the vane section be used for lifting.

2.3 MOUNTING

Depending on the type of fan support specified, the

fan can be floor mounted on legs, supported on a structural

frame or ceiling hung if clips or support brackets are included,

and again supported on the floor on a frame, or ceiling hung

if the fan is for vertical airflow.

2.3.1 Vibration Isolators

The fan is dynamically balanced to reduce vibration to

a low level. However, it is recommended that the fan be sup-

ported on vibration isolators. Isolators should be selected for

each installation in accordance with individual requirements.

The weight distribution between mounts is not equal

on Aerovent fans. Consult the factory for isolator selection

or mount loads. Isolators should be selected to support the

unequal load with equal deflection. A subbase can be used

to equally distribute the load to the isolators. Concrete inertia

pads are generally not required on Aerovent axial fans. When

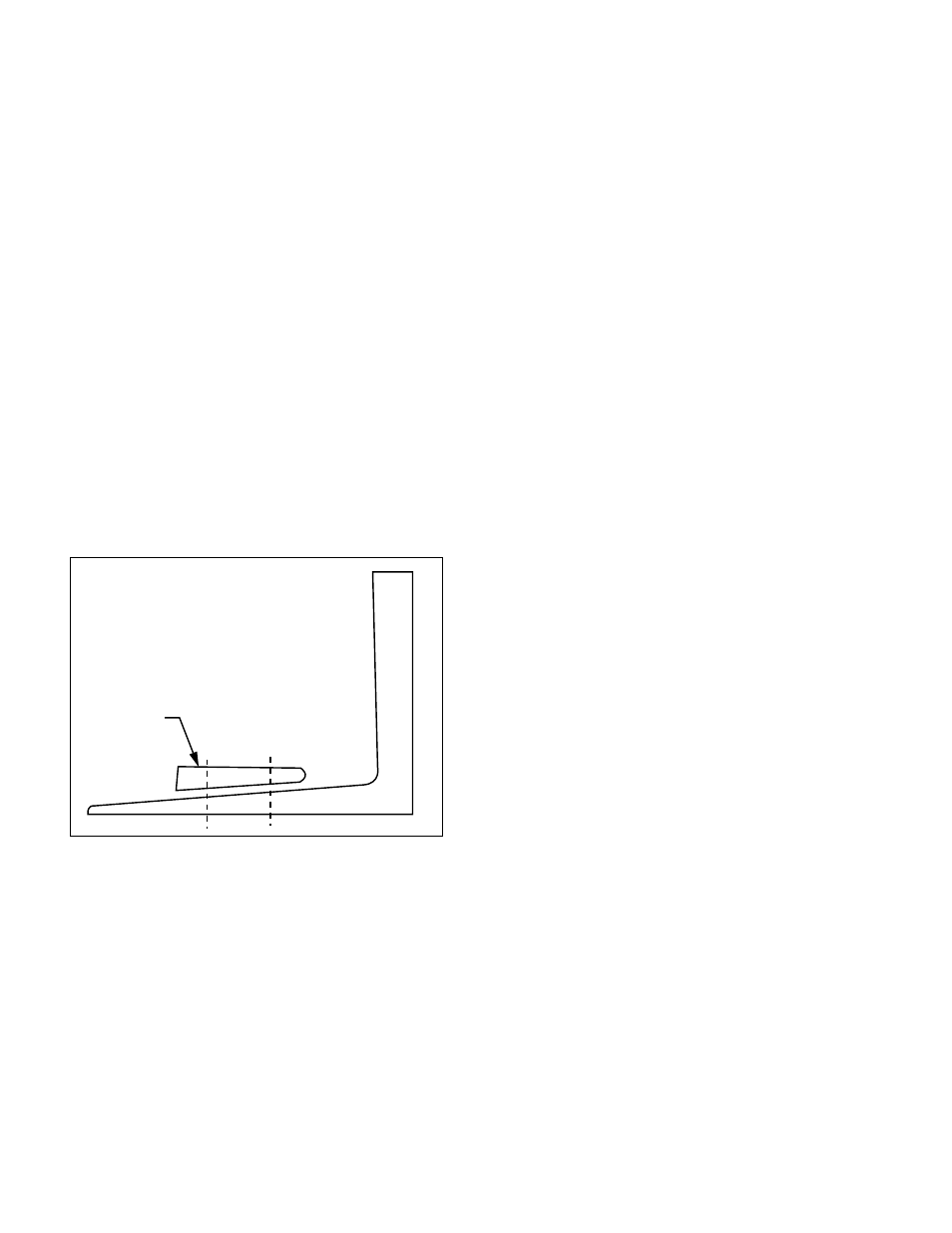

mounting isolators or tie-down bolts through the base frame

of an Arrangement 4 Type 3 fan, it is recommended that you

use a beveled washer between the base frame and the nut. See

Figure 1.

Figure 1.

2.3.2 Fan Reactions

It is essential to minimize fan movement due to start-

ing torque and air thrust force. These forces must be resisted

to maintain duct alignment and prevent damaging the flexible

connectors. Isolators must be selected with adequate stiffness

to resist these forces. Snubbers may be required in some instal-

lations to limit the fan movement.

2.4 DUCT CONNECTIONS

All fans should be closely aligned with the ductwork. A

flexible connection should be provided between the fan and

duct to prevent structure-borne noise from being transmit-

ted to the ductwork. Use band clamps and seal with Borden’s

Arabol, or equal, to insure mechanical security and prevent

leakage on all flexible connections.

NOTE: Provide a 1-inch to 2-inch gap between the fan

and duct to allow for fan movement.

2.4.1 Diffuser and Cone Connection

On AXICO fans, the standard discharge is not intend-

ed to be directly connected to the fan vane section. Support

the diffuser independently of the fan and provide a flexible

connection between the fan and the diffuser. On all Aerovent

fans, inlet cones can be directly connected and they also

become part of the load to be isolated.

2.4.2 Inlet Bell Connection

The inlet bell may be mounted in a plenum wall with a

flexible connection between the outer edge of the bell and a

hole in the partition. Provide a 2-inch to 3-inch gap to allow

for fan movement.

The inlet bell may be installed protruding into the ple-

num where space is limited. A metal ring should be installed

between the inlet bell and the case flange and a flexible con-

nection installed between the ring and the plenum wall.

2.5 ELECTRICAL

All wiring should conform to local electrical codes and

the job specification.

2.5.1 Power Connection

The motor leads terminate in the conduit box. The

leads are factory connected for the voltage specified for the

job. Motor leads for wye-delta and part-winding starts are

not connected. Rigid conduit should be run from the motor

starter to the fan with a short section of flexible conduit at the

conduit box to allow for fan movement.

Wire size and motor overloads should be sized in

accordance with the fan nameplate electrical data. The conduit

box is located on the outside of the case on all ducted, direct

driven fans. If the motor is outside the fan case, connection

will be made directly to the motor.

2.5.2 Motor Rotation

Check motor rotation by jogging the motor. The rota-

tion should be clockwise when viewed from the inlet of the

fan. Reverse any two motor leads to change rotation.

NOTE: It is important that correct motor rotation be

established on ducted fans as the rotor will not be visible after

an inlet duct is installed.

2.5.3 Electrical Data

If the fan is a variable pitch AXICO fan, it is recom-

mended that the fan not be run until the controls are opera-

tional. The fan should be started in accordance with Section

2.5.4 and the electrical data measured and compared to motor

nameplate ratings.

2.5.4 Final Check Before Putting

Fan Into Operation

1. Check for correct supply voltage and motor overloads.

2. Insure that all loose debris is removed from fan, fan

room, plenum and/or all ducts.

3. Check that motor bolts are tight and rotor is centered in

fan case with adequate blade tip clearance all- around. See

Section 6.6 for motor bolt torque data, and Section 6.7 for

minimum blade tip clearance.

4. Hand rotate and then bump the fan starter to check rota-

tion.

5. Start the fan and verify that the vibration is acceptable.

If the fan is a variable pitch AXICO, make the following

additional checks.

6. Check that the air supply pressure is correct (60 to 100

psig).

Beveled

Washer