0 maintenance – Aerovent IM-201 User Manual

Page 6

6

Aerovent IM-201

5.0 MAINTENANCE

5.1 GENERAL

Aerovent fans are a quality product designed and

manufactured for minimum maintenance and long operating

life. They should provide years of trouble-free service if the

following maintenance procedures are followed.

Aerovent fans are balanced at the factory to the fol-

lowing standards. NEMA has set standards for motor balance

which are also shown. Bearing life and lubrication require-

ments are based on the NEMA standard. The more stringent

Aerovent standards allow for normal build-up of dirt on

rotors; use, evaporation and/or shifting of lubricants; and

normal wear. If a fan appears to be out of balance, it is wise

to clean and grease before attempting to balance as this may

resolve the situation in the simplest manner.

In the event that the fan does not require dynamic bal-

ancing, balancing weights should be added as described in this

text.

Balance weights should be located only between the

blade hole openings and on the front and rear of the hub fair-

ing. See Figure 4.

Balance weights should not exceed the weight (in

grams) listed in Figure 4.

5.2 MOTOR LUBRICATION

Motor bearings do not require initial lubrication unless

the fan has been in storage over six months. If this is the case,

the motor should be lubricated initially.

Lubricate motor bearings with grease gun at the follow-

ing intervals and numbers of strokes:

NOTE: Normal amount of grease delivered by a hand car-

tridge type grease gun.

Use only the following lubricants or their equal:

Chevron SR-2

A.F. No.2

Precision No. 2

Shell Gadus S2 V100 2

Starfak H, M and No. 2

Mobilith AW2

Mobil Grease #77

The grease fittings must be clean to prevent contamination.

The fittings are located as follows:

CAUTION: Do not over lubricate bearings or use a grease

other than specified.

5.3 AXICO FAN LUBRICATION

5.3.1 Rotor

Rotor lubrication is described in Section 5.6 under

Routine Maintenance.

5.3.2 AXICO FPMC Lubrication

In addition to the above in Section 5.3.1, all FPMC

rotors have a thrust bearing in the hub cover. The grease lead

to this bearing is on the outside of the vane section. Grease

as per Section 5.2 should be applied, one stroke once a month

of fan usage.

The FPMC unit with handwheel adjustment has a

grease fitting on the jack inside the vane section in addition

to the thrust bearing. Unless the pitch is changed frequently,

there is no reason to lubricate this more often than as part of

the two-year maintenance procedure.

The FPMC unit with external electric operator requires

lubrication with SAE 30 motor oil at the pivot joints on the

linkage every six months. The actuator requires no lubrica-

tion.

5.4 AIR LEAKS ON AXICO FPAC FANS

If, during the monthly check, an AXICO FPAC fan is

found to be acting erratically, and if the problem is not in the

external control (indicated by a constant varying 3 to 15 psig

input signal), then check for air leaks.

Listen with your ear close to the positioner. If there

is an erratic sound of air escaping when the fan is at maxi-

mum pitch, replace the pilot on the positioner (part number

F10046301).

If the pressure to the diaphragm will not hold at the

same level as main air pressure when the control pressure is

15 psig, inspect for an air leak between the positioner and

the rotor. Shut the fan off, but maintain pressure to the dia-

phragm, and proceed as in Section 5.7 to remove the access

door to the vane section. Check the air line, the diaphragm

cover bolts, and the rotary union for leaks (turn fan by hand

to detect rotary union leaks).

If the rotary union is removed or replaced with a new

one, use Loctite Stainless Steel PST on the threads going into

the diaphragm cover.

5.5 SIX-MONTH INSPECTION

AND MAINTENANCE

The motor bearings may require lubrication depending

on motor size per Section 5.2.

The FPMC fan linkage should be lubricated per Section

5.3.2.

5.6 ANNUAL AND TWO-YEAR MAINTENANCE

A minor inspection of the AXICO rotor is required

every two years, but recommended each year for continuous

duty fans or fans operating with dirty or contaminated air.

Remove the access panel of the vane section as described in

Section 5.7 and inspect the blade links to be sure the spherical

bearings are not binding, and apply an aerosol lubricant such

as CRC or WD-40.

Grease blade shaft bearings by applying grease through

the fitting in the bearing housing until excess grease comes

past the seal. Wipe away excess.

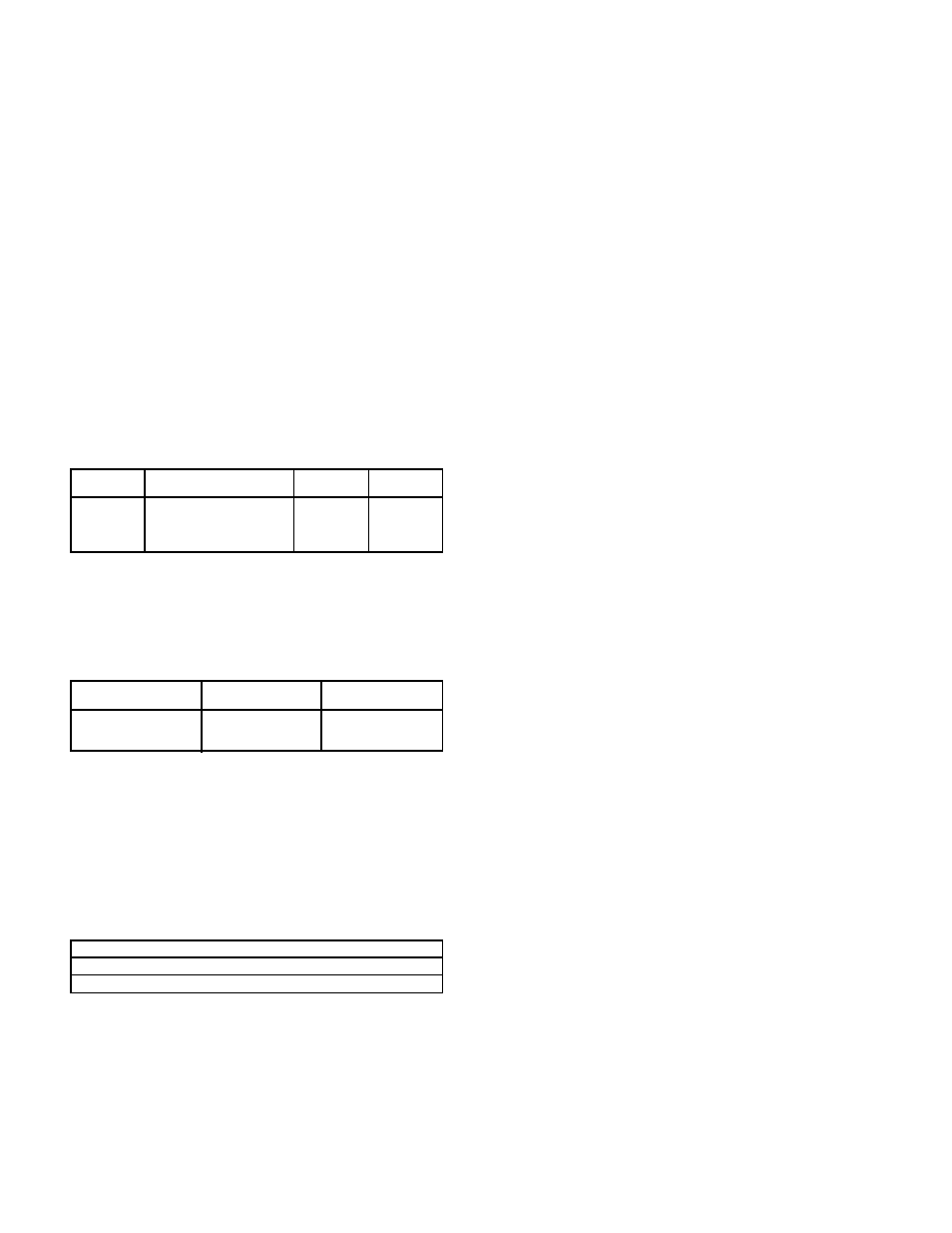

RPM

AEROVENT

SHUT-

MILS

STANDARD

DOWN

ALARM

3600

0.6 Mils Peak/Peak

2.20

1.42

1800

0.8 Mils Peak/Peak

4.40

2.84

1200

1.2 Mils Peak/Peak

6.70

4.26

900

1.6 Mils Peak/Peak

8.90

5.60

HORSEPOWER

PERIOD

STROKES

(SEE NOTE)

5 to 7

1

⁄

2

12 Month

1

10 to 40

6 to 12 Month

3

50 to 150

6 Month

3

TYPE FAN

LOCATION

Arrangement 4, Type 2

Fan case adjacent to conduit box

Arrangement 4, Type 3

End of motor base