0 axico fan blade adjustment – Aerovent IM-201 User Manual

Page 3

Aerovent IM-201

3

7. Set controller at a low set point for minimum pitch (3 psig

branch pressure to the positioner) for direct acting.

8. Verify once again that the vibration is acceptable.

9. Increase the set point for maximum pitch and measure

motor current. Check that full load current does not

exceed motor nameplate data. Also verify that the vibra-

tion level at full pitch is acceptable.

10. Verify that blade pitch changes smoothly throughout

the full range as the controller set point is moved. If the

AXICO fan has an electric operator, follow the same pro-

cedure except of course varying the signal input circuit to

the Honeywell electric opener.

3.0 AXICO FAN BLADE ADJUSTMENT

3.1 FPAC FAN

The FPAC fan has a pneumatic diaphragm incorpo-

rated in the hub to operate the blade pitch changing mecha-

nism. Air is supplied to the diaphragm through a rotary union

connected to a valve positioner mounted n the vane section.

The positioner is mechanically connected to the diaphragm by

a flexible cable.

3.1.1 Positioner — Function

The function of the positioner is to modulate the air

pressure to the diaphragm in response to the control pressure.

By means of the mechanical feedback it can sense the blade

pitch and thus satisfy the control set point. The positioner will

provide linear response to the control pressure.

The positioner is factory set to operate in the direct act-

ing mode. This means that a decreasing control pressure will

cause a decrease in blade pitch and less airflow.

3.1.2 General Description of How It Works

The pilot positioner is a single acting, singe-stage,

force-balance type control device. Mounted on an AXICO

fan, and cable-connected to the rotor operating mechanism, it

uses an auxiliary air supply and a feedback cam controlled by

the cable to position the rotor mechanism in accordance with

the 3-15 psig air signal from the controller.

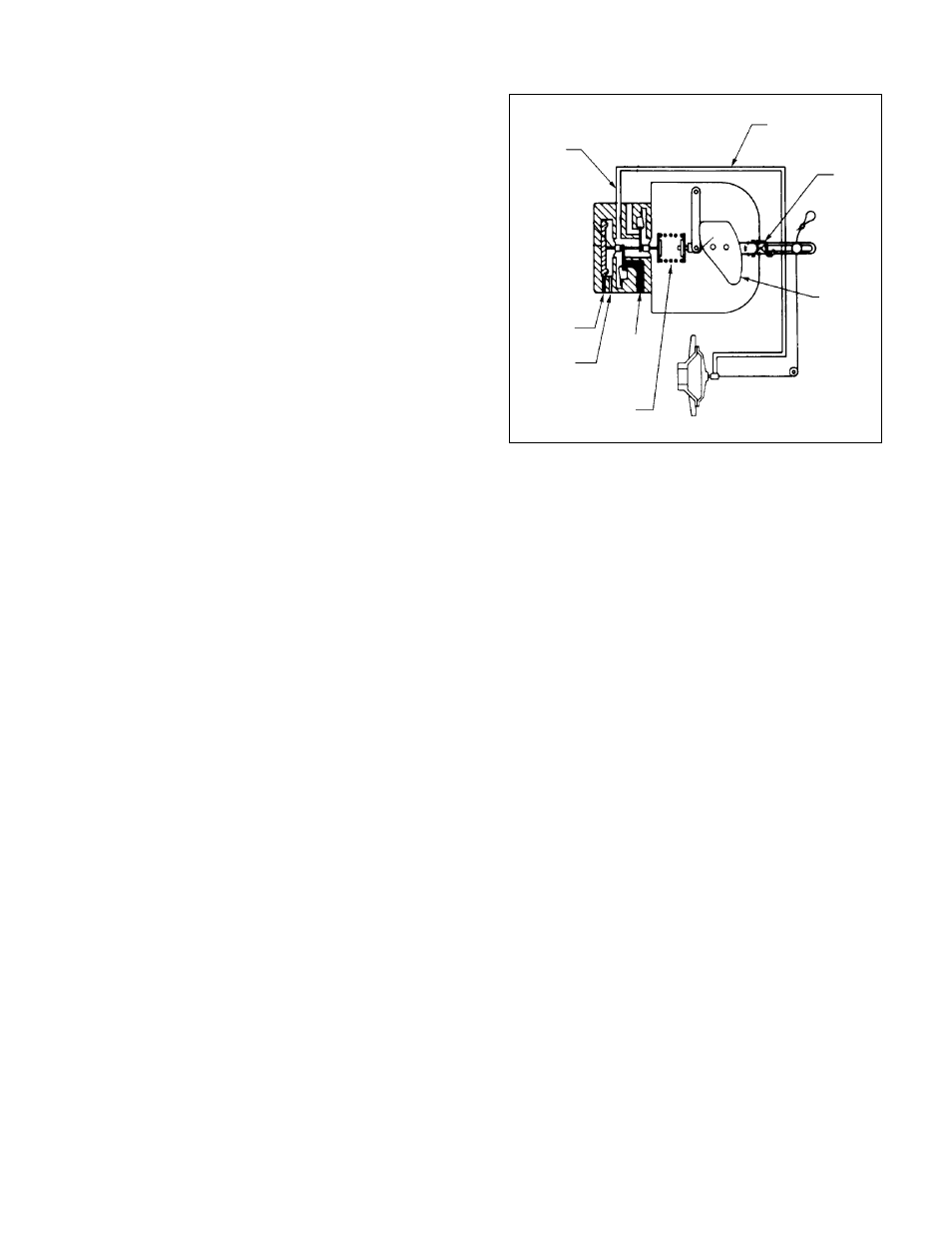

Figure 2 is a schematic diagram of this system.

Remember that the feedback spring maintains upward pres-

sure on the positioner arm at all times, and this keeps the

cable in tension. Since the positioner is direct acting, a 3 psig

instrument gauge pressure results in 0 psig valve gauge pres-

sure or minimum pitch position. When the instrument gauge

indicates 15 psig, this results in maximum valve pressure and

thus maximum pitch. The tendency of the fan blades is to go

to minimum pitch, so that, when the diaphragm pressure is

reduced, the spider will move towards the rotor, pulling the

positioner arm down and compressing the feedback spring.

3.1.3 Positioner Connections

There are three

1

∕

4

" NPT ports on the positioner. The

top port is connected to the diaphragm on the fan rotor.

The middle port should be field connected to the controller

(branch line). The bottom port should be field connected to

main air supply.

Supply air should be clean and dry instru-

ment air. Moisture or dirt in the supply air will cause

the pilot on the positioner to malfunction after repeated

exposure. The supply pressure to the positioner should be

regulated as required to achieve full pitch. The supply pressure

needed is a function of fan speed and size.

3.1.4 Positioner Calibration and Adjustment

The positioner is factory calibrated and no further

adjustment is normally required. The calibration can be eas-

ily checked and corrected if normal fan control cannot be

achieved. The positioner must be adjusted if replaced or the

cable is removed from the lever arm.

To adjust the positioner, proceed as follows:

1. With fan off, disconnect the air line on the positioner to

the fan rotor and connect this line to a

1

∕

4

" NPT pressure

regulator.

2. Check that the cable is in alignment with the hole where

it enters the stator vane core. If not, adjust the positioner

on the mounting bracket (not the pin in the slotted arm),

keeping the positioner horizontal with respect to the case.

3. Adjust the pressure regulator to supply full line pressure

to the fan diaphragm. Loosen the cable clamp on the

positioner arm and pull cable tight. Mark the cable where

it protrudes through the stator case. This is the maximum

pitch position. Reduce the pressure to the diaphragm to

zero and start the fan while maintaining tension on the

cable by pulling upward on the cable. The fan will now be

in the minimum pitch position.

Mark the cable again in the minimum pitch position. Turn

off the fan.

WARNING: Do not release cable tension while fan is in

operation. Wait until fan has come to a complete stop.

NOTE: The blades may not fully return to the minimum

pitch position unless fan is operating.

4. Adjust the pressure to the diaphragm to move the cable

midway between the two reference marks. Measure care-

fully and maintain this position. Remove the side cover

plate on the positioner. Grasp the positioner arm and move

it to align the line engraved on the cam with the centerline

of the cam roller (see Figure 2). Tighten the cable clamp.

NOTE: The positioner is now mechanically adjusted at

mid-range with the fan blade pitch mechanism at the mid

position.

Zero

Return

Spring

Valve Air

Operating

Air To

Diaphragm

(Top Port)

Feedback

Cam

Feedback

Spring

Controller

Input Signal

Air (Middle

Port)

Vent

Main Air

Supply

(Bottom

Port)

Fan Rotor

Figure 2. Schematic of Pilot Positioner and

Direct Acting FPAC Fan