210 torque hub, 10 torque hub -20, Torque hub removal -20 – Snorkel LX41 Electric-sn4022+ User Manual

Page 58: Figure 2-17: torque hub assembly -20, 10 t

Torque Hub

Section 2 - Service and Repair

Page 2-20

067448-003 LX31/LX41 Electric Work Platform

2-10 T

ORQUE

H

UB

C A U T I O N

Clean all fittings before disconnecting the hose assemblies.

Plug all port holes and hose assemblies IMMEDIATELY to prevent contamination from dust and debris.

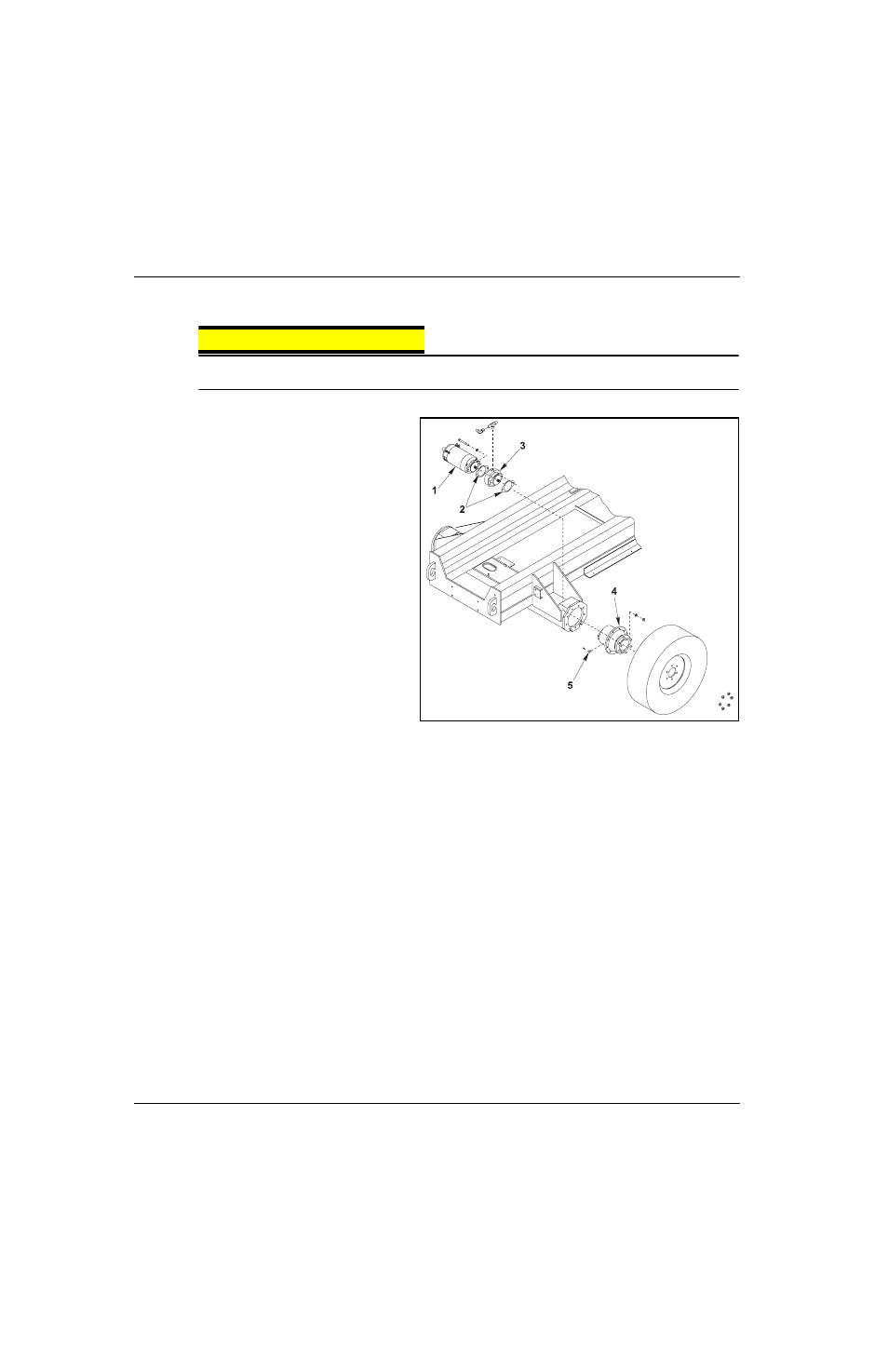

Figure 2-17: Torque Hub Assembly

T

O R Q U E

H

U B

R

E M O V A L

1. Park the work platform on firm level

ground and block the wheels to pre-

vent the work platform from rolling.

2. Disconnect battery negative terminals

or Anderson connectors (both sides

on electric model).

3. Loosen the wheel lug nuts on the

torque hub to be removed.

4. Raise the rear of the work platform

using a 2-ton jack.

5. Position two 2-ton jack stands under

the rear axle to prevent the work plat-

form from falling if the jack fails.

6. Remove the wheel nuts and wheel.

7. Disconnect hydraulic brake line from

brake.

8. Remove 90° fitting from side of torque

hub.

9. Tag and remove electric cables from drive motors.

10. Remove mounting bolts from electric motor.

11. Separate electric motor from brake. Discard gasket.

12. Separate brake from torque hub. Discard gasket.

13. Remove ½-20 nuts and washers from torque hub.

14. Remove torque hub.

IMPORTANT: Note position of 90° fitting on torque hub body. Hub must be installed with fitting in same position.

1 Motor

2. Gasket

3. Brake

4. Torque Hub

5. 90° Fitting