24 lubrication, 4 lubrication -9, Grease fittings -9 torque hubs -9 – Snorkel LX41 Electric-sn4022+ User Manual

Page 47: Figure 2-3: lubrication points -9

Section 2 - Service and Repair

Lubrication

067448-003 LX31/LX41 Electric Work Platform

Page 2-9

2-4 L

UBRICATION

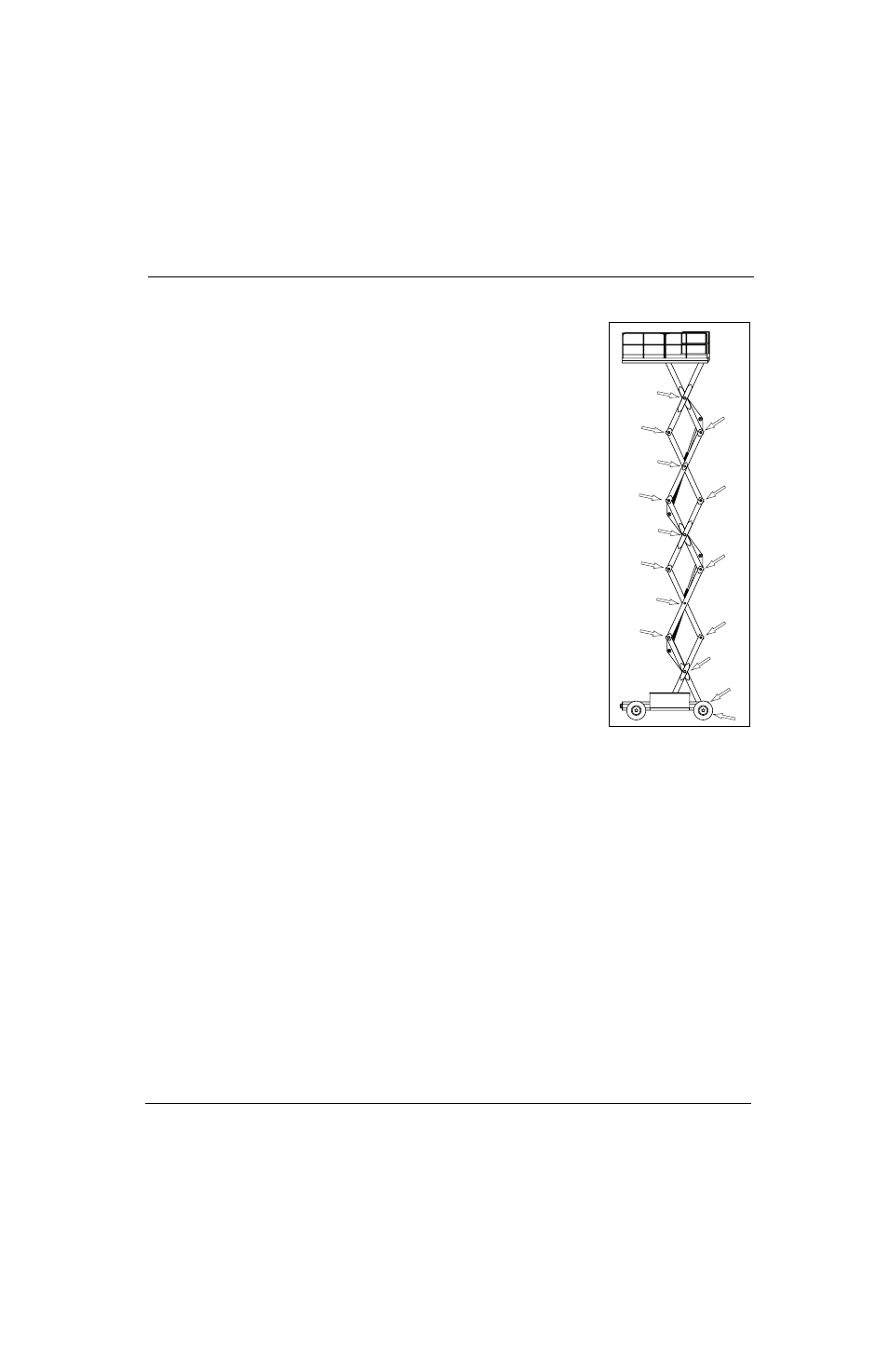

Figure 2-3: Lubrication Points

Refer to “Preventative Maintenance Check List” on page 2-7 for lubrication

intervals and Figure 2-3 for location of items that require lubrication service.

Refer to the appropriate sections for lubrication information on the steering

linkage, torque hubs, hydraulic fluid and filter.

G

R E A S E

F

I T T I N G S

Grease fittings at;

• the pivot points on the elevating assembly and

• the top and bottom of the steering pivots next to the front wheels.

Wipe each grease fitting before and after applying grease. Using multipur-

pose grease in a grease gun. Pump the grease into the fitting until grease

just begins to appear at the edges of the pivot and wipe off any excess

grease.

T

O R Q U E

H

U B S

NOTE:

Change oil in torque hubs after the first 50 hours of operation. Change every

1000 hours thereafter.

1. Remove the torque hub (refer to “Torque Hub Removal” on page 2-20).

2. Remove the drain plug from the underside of the torque hub.

3. Drain the oil from the unit.

4. Replace the drain plug.

5. Remove the fill plug from the top of the torque hub.

6. Using 90 weight gear lube with EP additive, fill the torque hub through the top plug hole in the rear cover

until oil comes out of the 90° fitting on the side. Plug the 90° fitting.

7. Replace the fill plug.

8. Install the torque hub (refer to “Torque Hub Installation” on page 2-21).