Begin pouring – MBW CG200 User Manual

Page 35

33

BEGIN POURING:

1. Make sure the Height Sensor

switch is flipped to the POUR posiĆ

tion.

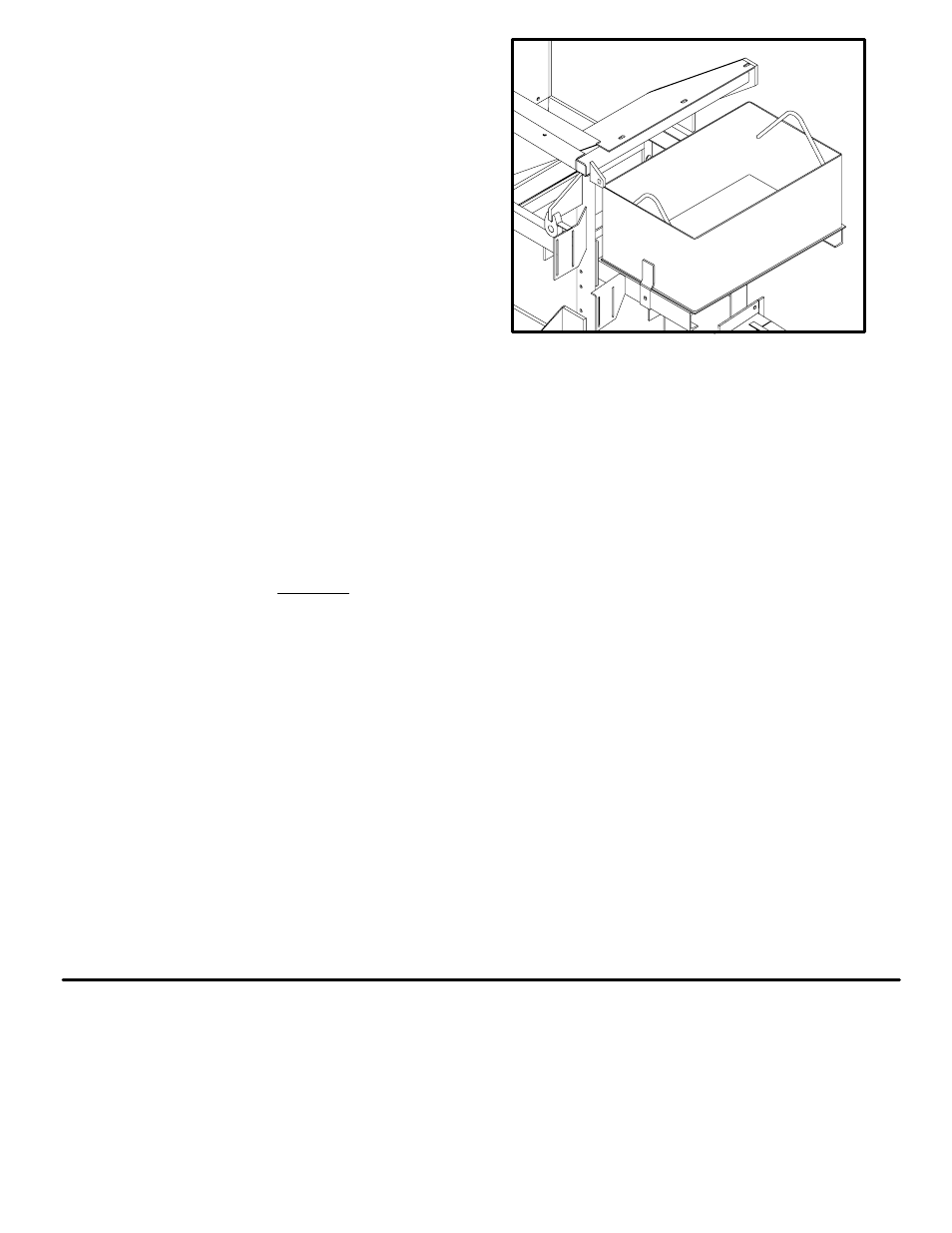

2. First Pour: Fill weight box (above

mold) with concrete.

3. Spray hopper area and mold inside

and outside with form oil. Fill hopĆ

per to within 8" to 10" of the top with

standard slip form paver concrete

mixture. (See operating hints for

concrete mix, page 36.)

4. Proceed with pour. Adjust vibrator potentiometers as required to fill mold and

aid flow of concrete into curb area. Lower slump concrete will require higher

vibrator settings to fill the form. Generally, start with vibrators set between 5

and 6.

5. If the engine is lugging or the exhaust is exceptionally black, check the position

of the vibrator pots. It is recommended that all three vibrator pots be set at

approximately the same position. Unused vibrators should be turned off. This

reduces the hydraulic load on the engine.

6. The three main manual operator functions while pouring are

1. Adjusting vibrator speed.

2. Adjusting travel speed.

3. adjust the pitch of mold from front to back by rising or lowering the front

cylinder. Use the black mark on the front steering sensor wand as a reference

mark.

4. The above three settings will be determined by the concrete mix.

7. To move back of curb away from the stringline move the steering sensor closer

to the stringline.

8. To move back of curb closer to the stringline move the steering sensor away

from the stringline.

9. To change top of curb height, use the height trim knob. Move clockwise (+) to

raise the curb and counterĆclockwise (Ć) to lower the curb.

NOTE: Fewer adjustments are better than many.