Automatic sensor set-up – MBW CG200 User Manual

Page 29

27

AUTOMATIC SENSOR SET-UP:

1. Install sensors. (See INSTALLING SENSORS", page 22.)

2. Drive Paver to string line. Left side of curb mold should be about 18" to 24" from

the string line. (6" to 12" for curb only). Bottom edge of mold (or mold edge

bars) should be about 0" to 1/4" above grade level. Front wheel should point

straight forward.

3. Manually level machine right-left. Adjust rear height to be slightly above front

height for grading. Adjust front height to be slightly above rear height for pourĆ

ing. This will ensure proper mold angle to provide pressure on concrete exiting

the form.

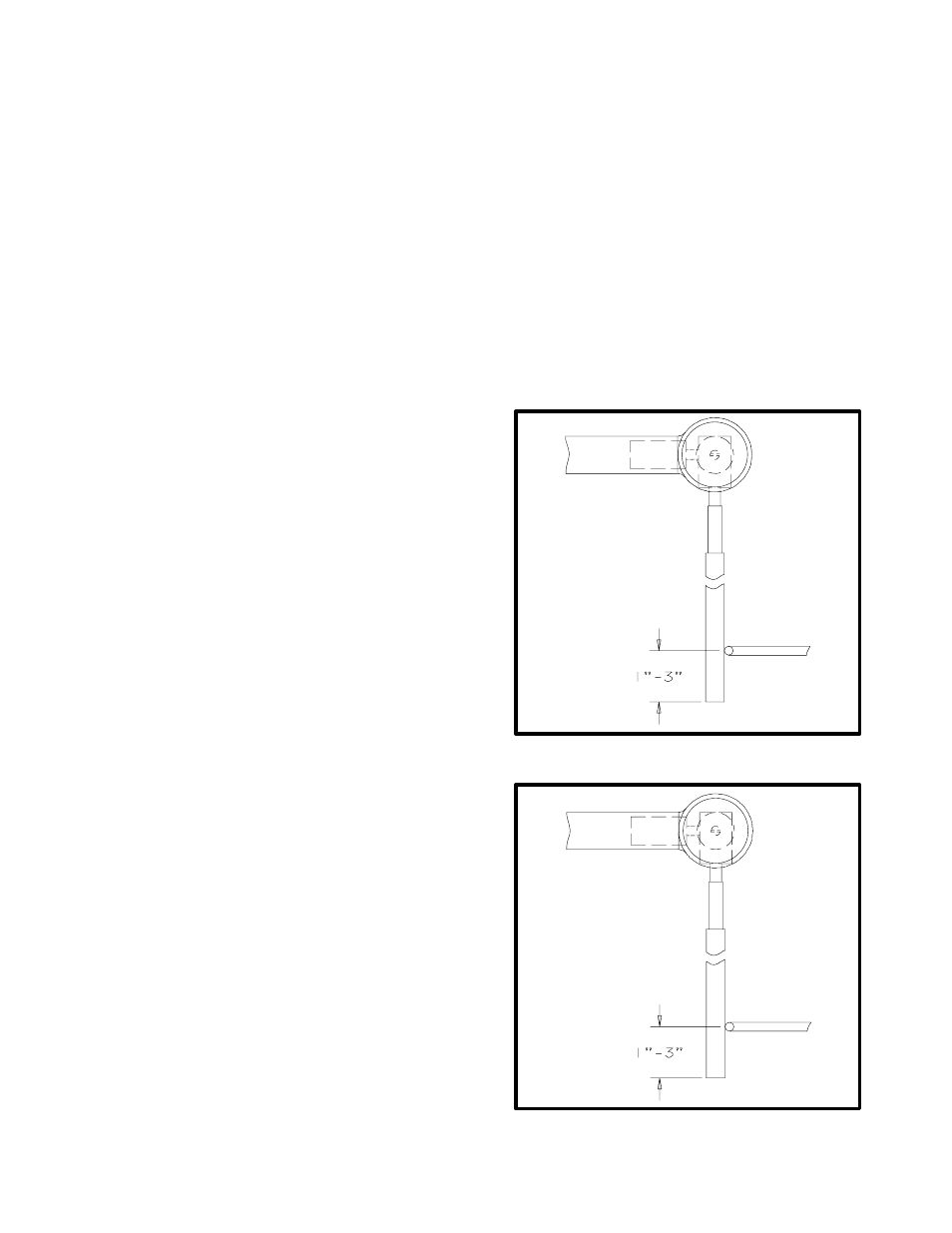

4. Front steering sensor: Install senĆ

sor with potentiometer shaft facing

backward. Adjust sensor head horĆ

izontally so that it is directly above

the string line. Install wand hangĆ

ing straight down with wand weight

to the inside. Adjust sensor vertiĆ

cally until string line is approxiĆ

mately 1" to 3" above the end of

wand. Adjust sensor potentiomeĆ

ter shaft so that screw driver slot is

horizontal. Tighten wand counter

balance weight to secure wand to

sensor.

5. Rear steering sensor: Follow steps

as listed for the front sensor.

Note: 12" molds incorporate a slidĆ

ing rear steering sensor bracket.

This allows the paver to turn a very

tight radius, while in automatic

mode. Slide the bracket towards

the rear of the mold to turn a tight

radius and to the front for a larger

radius.

Note: Only one height sensor can be used at a time. Front (grade) or rear (pour).

Only one steering sensor can be used at a time. Front or rear.