Attaching hopper – MBW CG200 User Manual

Page 21

19

ATTACHING HOPPER:

1. Position the hopper unit level on

the ground. Back off the three hopĆ

per joining nuts. (Two on main unit,

one on hopper.)

2. Lower the Main unit so that the joinĆ

ing studs and mating slots are

approximately the same height

and back the Main unit up to the

Hopper unit at an angle.

3. Continue backing until the rear stud begins to engage. Cut the front wheel hard

right and continue backing until front studs engage. Tighten the nuts.

4. When using a hopper without the Side Drive Unit, flip the Side Drive Unit switch

to Detached". (Transfers auto-height control to center cylinder.)

5. With hoppers (24" and wider) using the Side Drive Unit, flip the Side Drive Unit

switch to Attached". (Transfers auto-height control to side drive unit cylinder.)

6. When not using the Side Drive Unit or the optional right rear drive wheel, the

Rear Drive switches (left or right) must be off. If the Rear Drive switch is left on,

the machine will not move.

7. When using the Side Drive Unit or the optional right rear drive wheel, the Rear

Drive switch (left or right) may be in one of two positions:

1. ON: drive is on and drives with the

front wheel.

2. OFF: drive is off and free wheels.

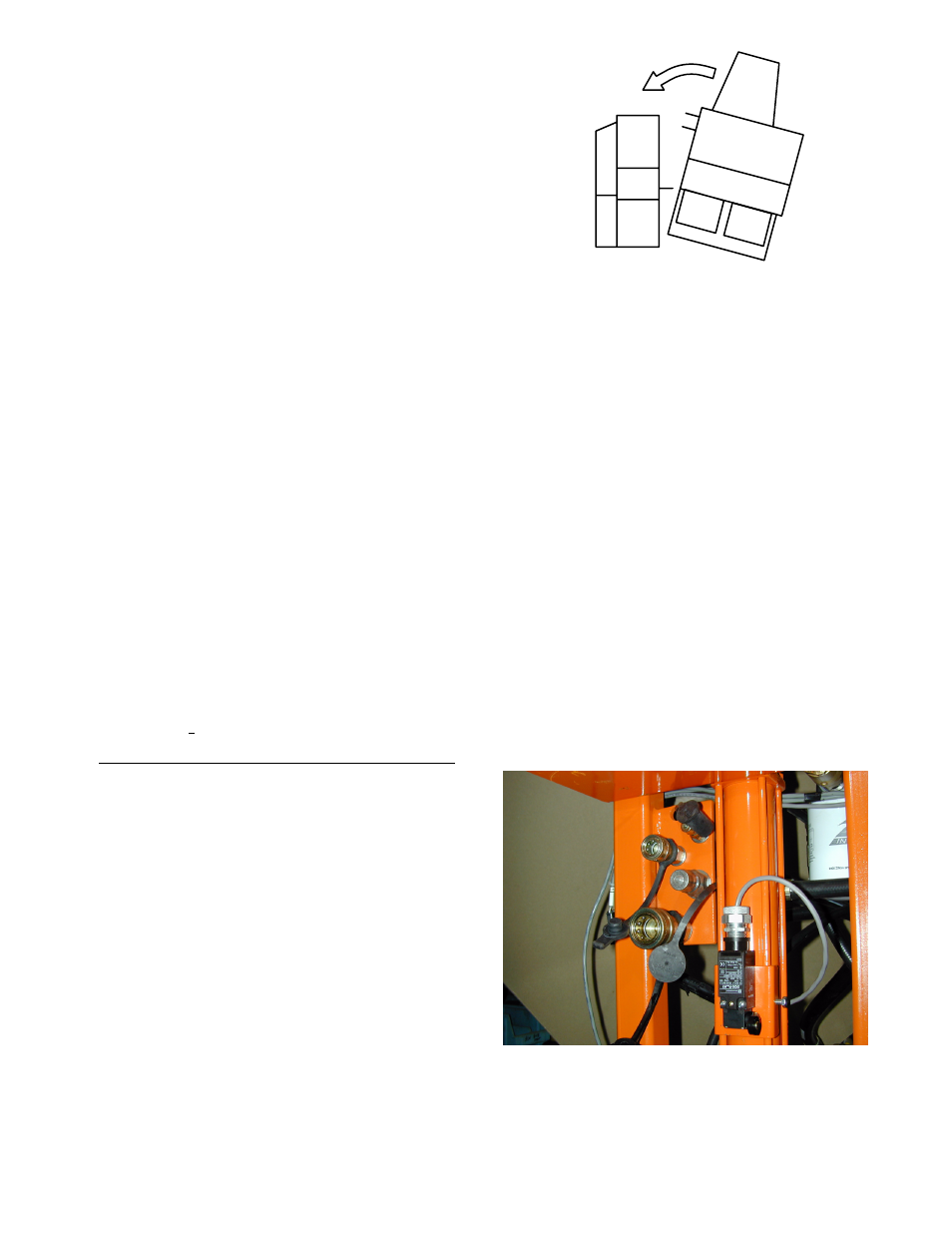

8. Connect hydraulic hoses as reĆ

quired.

NOTE: with the 12" hopper attached

S The side drive unit switch must be

switched to the detached position.

S The left drive wheel must be switch

off.

S The #3 or unused vibrator must be

turned off completely

S If either the left drive wheel or unĆ

used vibrator is switched on" the

hydraulic system will dead head (a

restricted flow of hydraulic fluid that

will kill the engine).